Plasma treatment method

A plasma and reactive gas technology, applied in the field of plasma treatment, can solve problems such as poor results and poor plasma stability, and achieve the effects of improving stability, ensuring continuous ignition, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned in the background, in the existing plasma treatment process, the stability of the plasma is relatively poor, which easily leads to poor results of the plasma treatment.

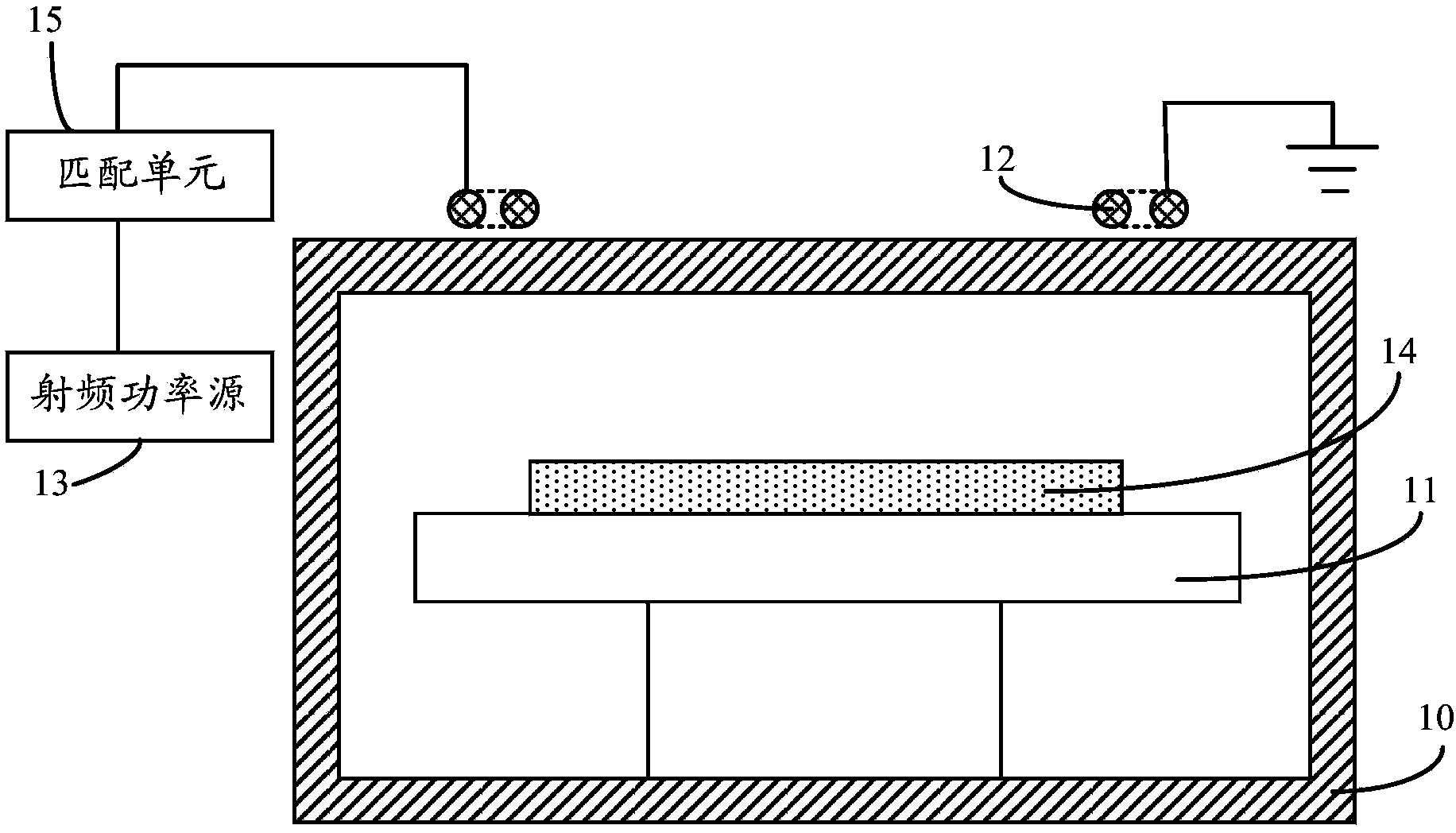

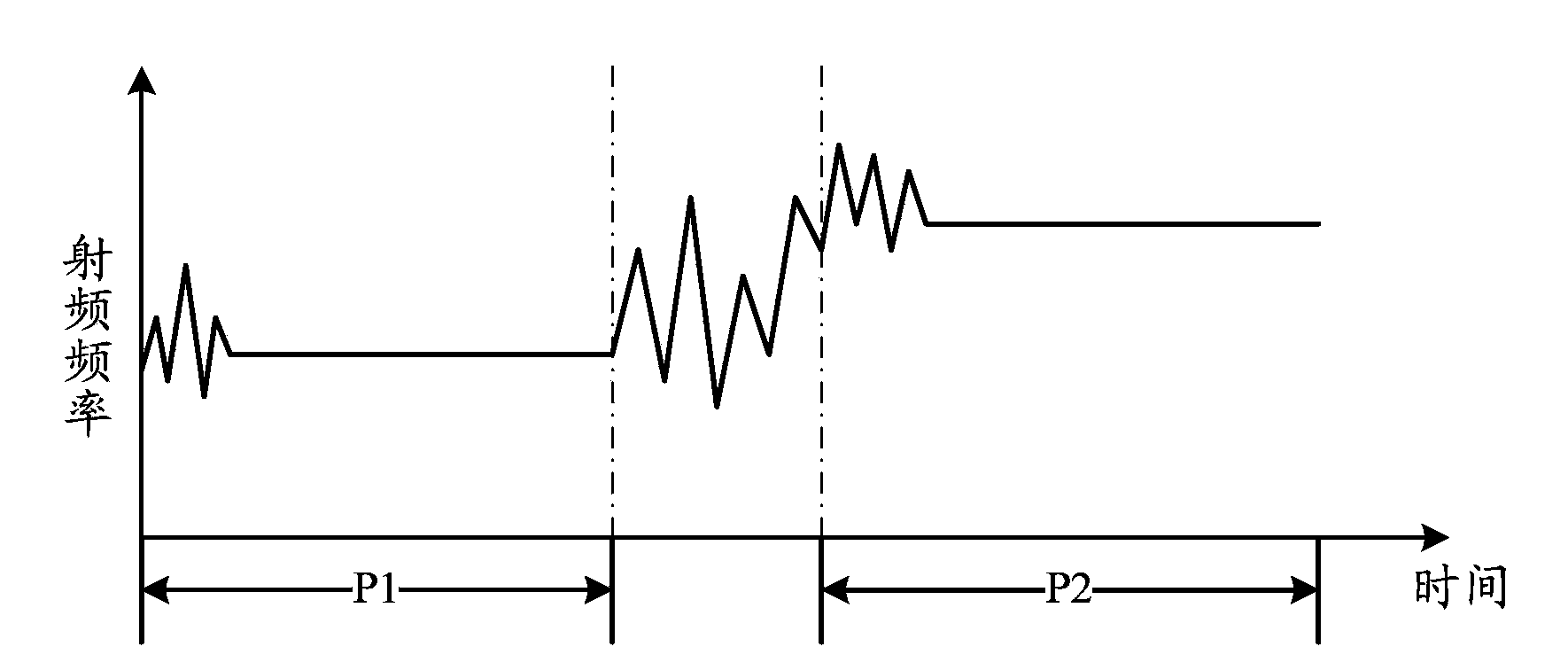

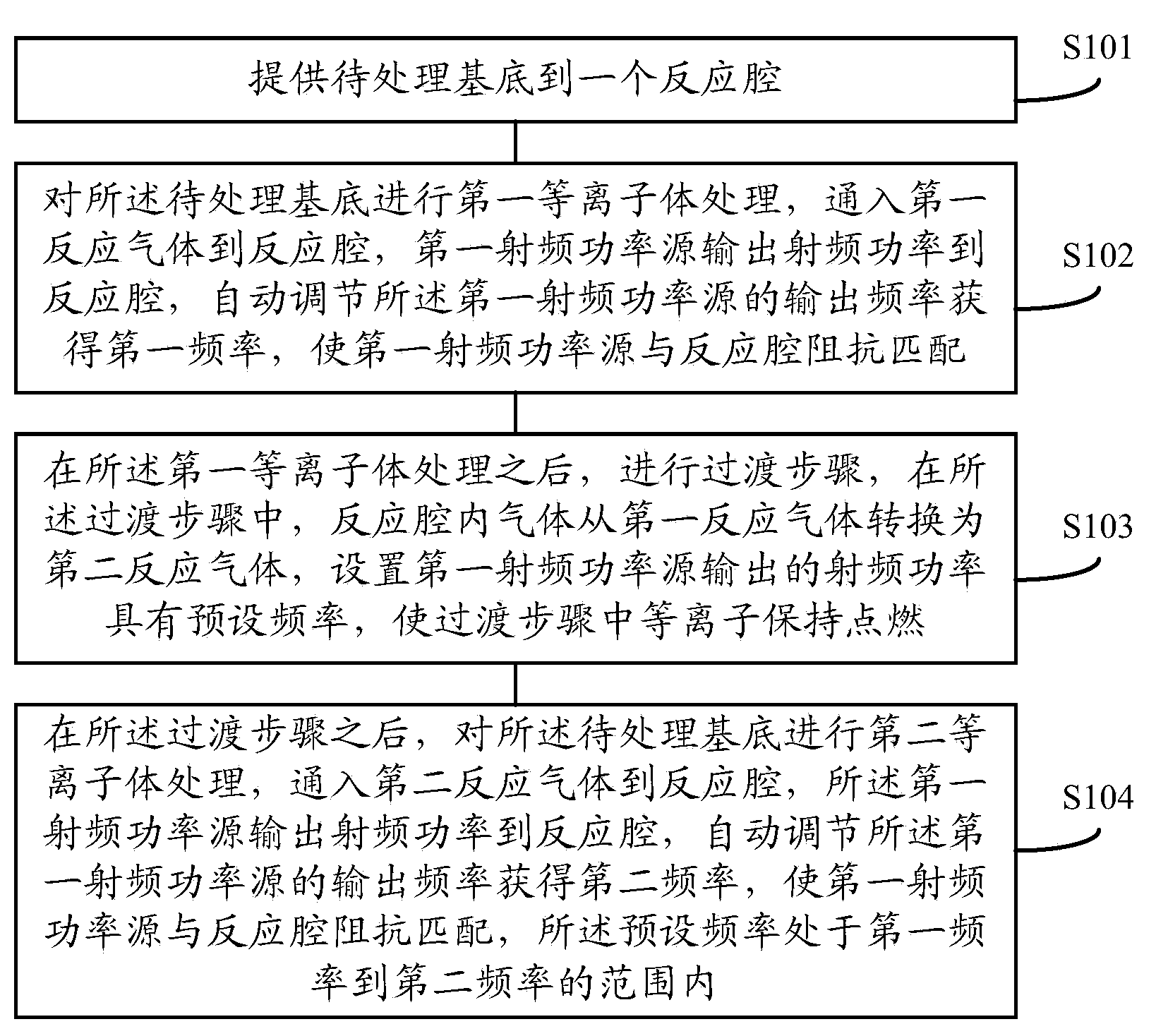

[0029] Please continue to refer figure 1 , in the existing plasma processing device, the power supply 13 provides radio frequency power to the inductively coupled coil 12 arranged on the top of the reaction chamber 10 through the matching unit 15, and the inductively coupled coil 12 causes the plasma to be generated in the reaction chamber 10, so The plasma in the reaction chamber 10 is the load of the power supply 13 . With the progress of the plasma treatment process, it is often necessary to perform multiple continuous process steps. For two adjacent process steps, the frequency of the pulse signal output by the power supply 13 needs to change, and the gas composition in the reaction chamber 10, The gas pressure will also change with the change of the process, thus causing the impedanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com