Normal pressure intermittent natural gas reforming process and device

A natural gas, intermittent technology, applied in the direction of sustainable manufacturing/processing, gas fuel, chemical industry, etc., can solve the problems of low energy conversion efficiency and high calorific value of reformed gas, so as to reduce calorific value, save energy and improve conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

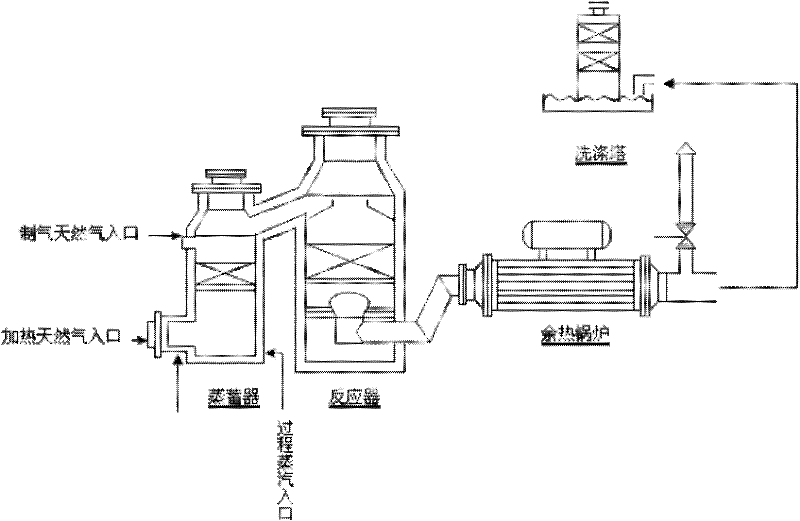

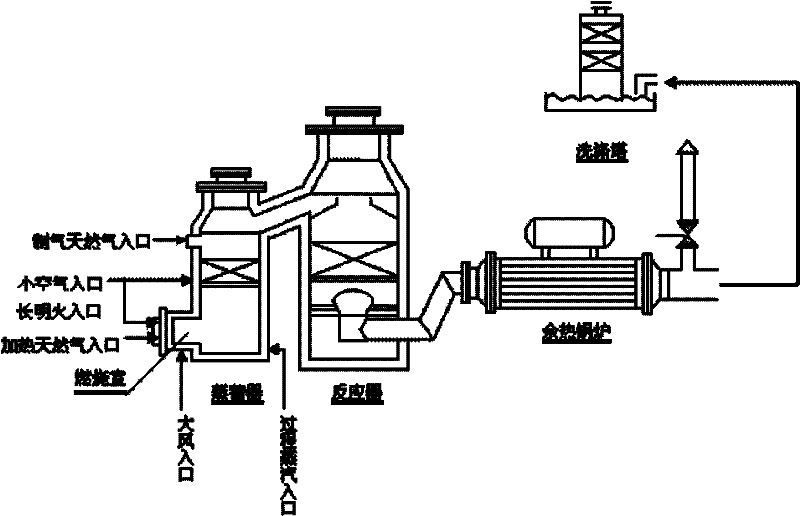

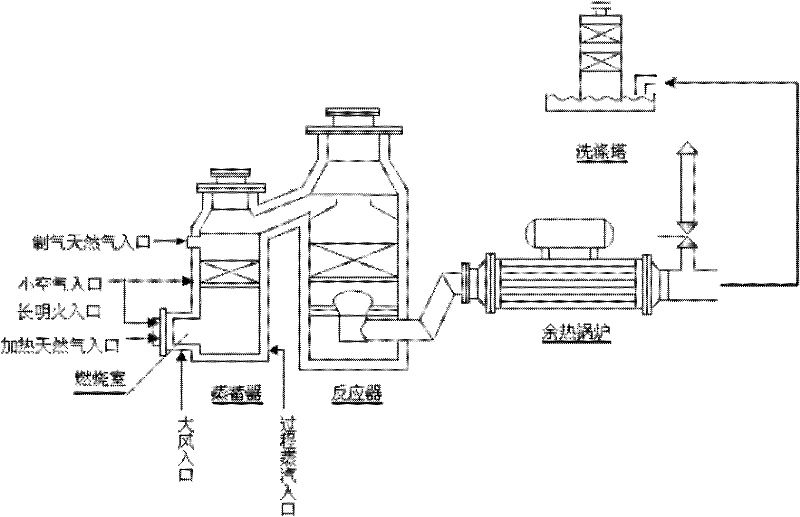

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0024] In order to improve the energy conversion efficiency of urban gas, the calorific value of the reformed gas needs to be reduced. One of the ways to reduce the calorific value is to increase a certain amount of waste gas, which can effectively reduce the calorific value of the reformed gas. And increasing the amount of waste gas can be obtained by adopting the following steps in the process flow:

[0025] 1. Increase the amount of small air

[0026] Entering a small amount of air (also called small air) at the bottom of the steam-accumulator during gas production can increase the temperature of the catalytic bed, and at the same time, the effect of small air can make the produced modified gas contain waste gas, reducing the calorific value of the modified gas. The amount of direct blending of natural gas has been increased.

[0027] 2. Add p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com