Waste heat comprehensive utilization device during the production process of fumaric acid

A production process, fumaric acid technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of heat and water waste, steam pressure fluctuation, unstable consumption, etc., to save energy and production costs, the effect of improving the cooling effect and efficiency of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

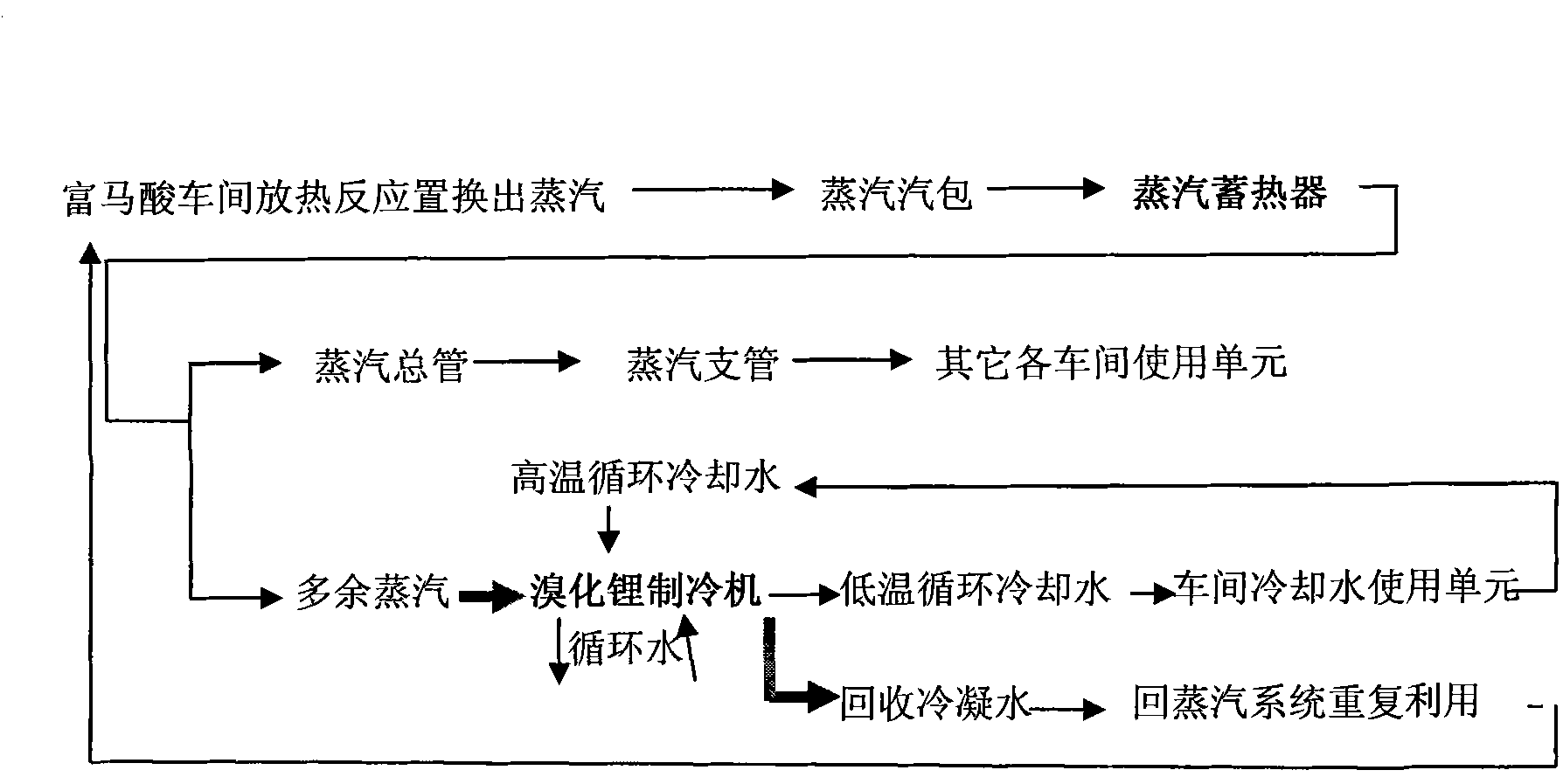

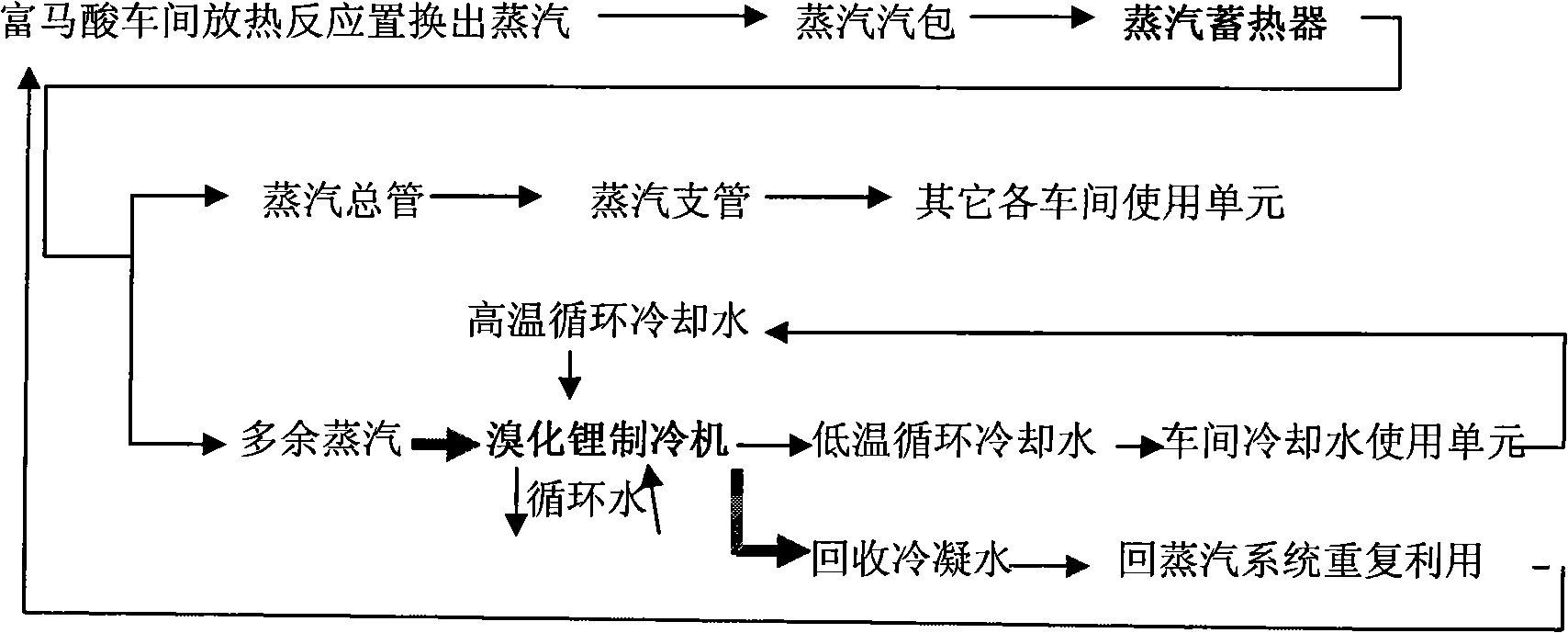

[0008] Fumaric acid production process waste heat comprehensive utilization device, including the steam drum connected with the exothermic reaction displacement steam of the fumaric acid workshop, the steam main pipe and steam branch pipe connected with other steam use workshops of fumaric acid production, and the steam drum pipe connection A steam accumulator, the main steam pipe is connected to the steam accumulator, and another pipeline of the steam accumulator is connected to the lithium bromide refrigerator.

[0009] There are three sets of pipelines entering and leaving the lithium bromide refrigerator: the steam condensate of the lithium bromide refrigerator is connected to the steam system circulation through the recovery pipe; the low-temperature circulating cooling water of the lithium bromide refrigerator is connected to each workshop by the pipeline, and the high-temperature circulating cooling water generated is connected to the lithium bromide Refrigerator; the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com