Garbage treating method

A garbage treatment and garbage technology, applied in the direction of solid waste removal, etc., can solve problems such as hindering urban development, difficulty, and complex chemical components of waste gas, and achieve the effect of improving steam utilization and reducing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

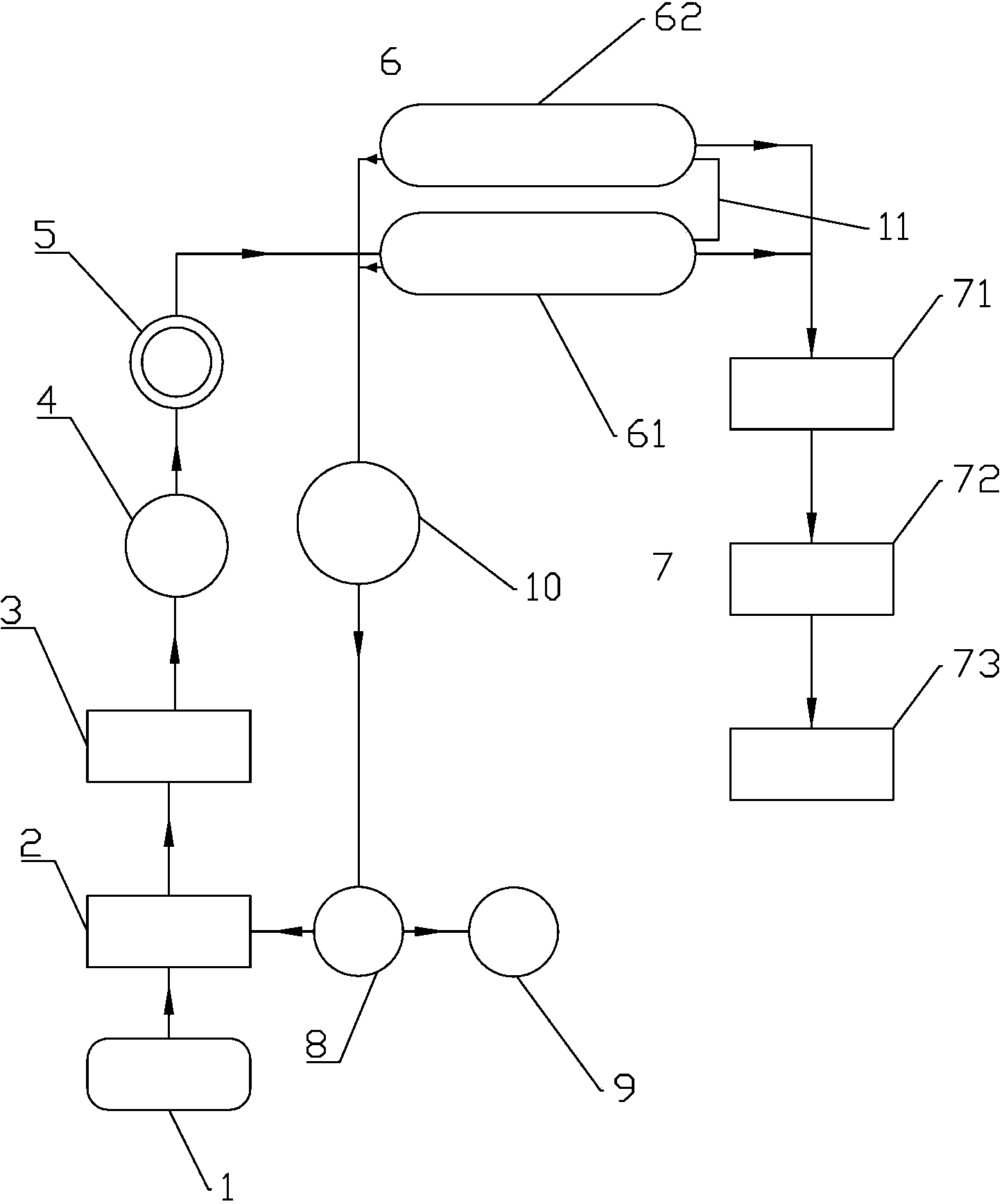

[0036] Such as figure 1 , a garbage treatment system, the water source 1 is connected to the water quality treatment device 2, the water quality treatment device 2 is connected to the water supply tank 3, the water supply tank 3 is connected to the steam boiler 4, the steam boiler 4 is connected to the steam heat accumulator 5, and the steam heat accumulator 5 is connected to the steam reactor 61 in the steam reactor group 6, the steam reactor group 6 is connected to the screening device 7, and the screening device 7 is composed of an organic fiber screening device 71, a metal screening device 72, and a non-metallic screening device 73 connected in sequence, The steam reactor group 6 is composed of steam reactors 61 and 62 interconnected by pipelines.

[0037] The steam reactor group 6 is also connected to the collector 10, the collector 10 is connected to the steam cooling device 8, the steam cooling device 8 is connected to the water quality treatment device 2, and the steam...

Embodiment 2

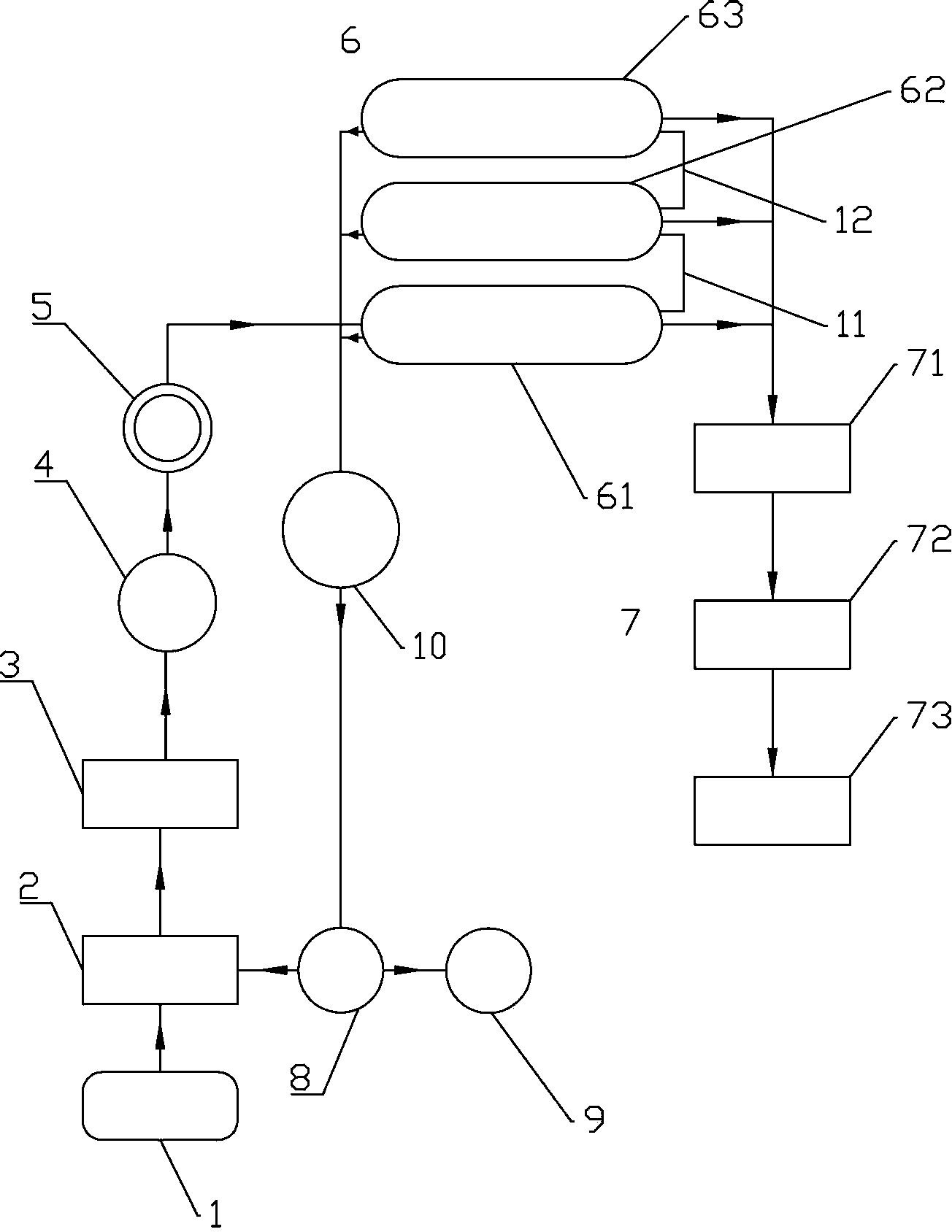

[0041] Such as figure 2 , a garbage treatment system, the water source 1 is connected to the water quality treatment device 2, the water quality treatment device 2 is connected to the water supply tank 3, the water supply tank 3 is connected to the steam boiler 4, the steam boiler 4 is connected to the steam heat accumulator 5, and the steam heat accumulator 5 is connected to the steam reactor 61 in the steam reactor group 6, the steam reactor group 6 is connected to the screening device 7, and the screening device 7 is composed of an organic fiber screening device 71, a metal screening device 72, and a non-metallic screening device 73 connected in sequence, The steam reactor group 6 is composed of steam reactors 61, 62, 63 interconnected by pipelines.

[0042] The steam reactor group 6 is also connected to the collector 10, the collector 10 is connected to the steam cooling device 8, the steam cooling device 8 is connected to the water quality treatment device 2, and the ste...

Embodiment 3

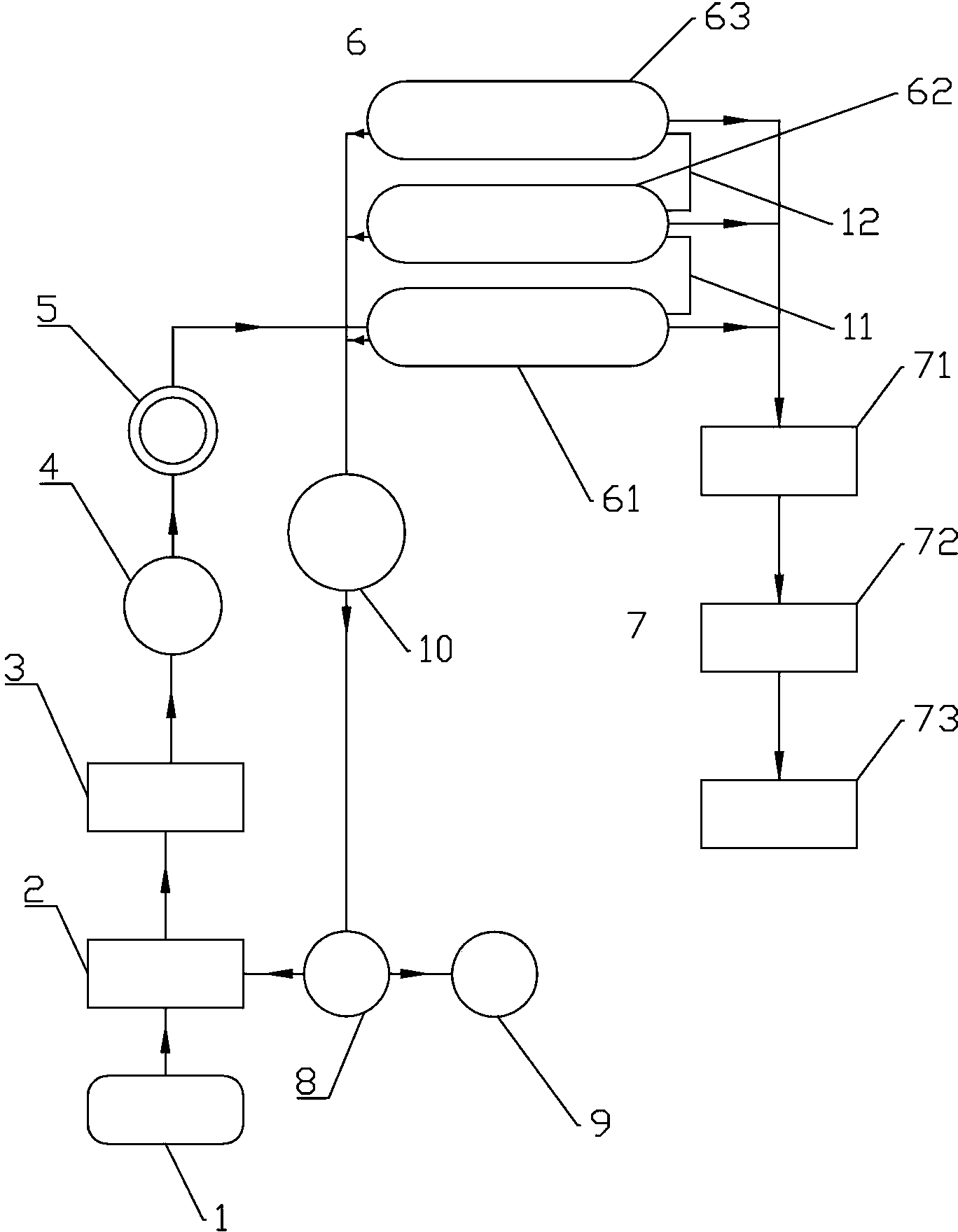

[0046] Such as image 3 , a garbage treatment system, the water source 1 is connected to the water quality treatment device 2, the water quality treatment device 2 is connected to the water supply tank 3, the water supply tank 3 is connected to the steam boiler 4, the steam boiler 4 is connected to the steam heat accumulator 5, and the steam heat accumulator 5 is connected to the steam reactor 61 in the steam reactor group 6, the steam reactor group 6 is connected to the screening device 7, and the screening device 7 is composed of an organic fiber screening device 71, a metal screening device 72, and a non-metallic screening device 73 connected in sequence, The steam reactor group 6 is composed of steam reactors 61, 62, 63 interconnected by pipelines.

[0047] The steam reactor group 6 is also connected to the collector 10, the collector 10 is connected to the steam cooling device 8, the steam cooling device 8 is connected to the water quality treatment device 2, and the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com