Coal gas, converter steam and sintering waste heat combined power generation device and waste heat utilization method

A combined power generation and steam technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of poor system stability, large investment, and high operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

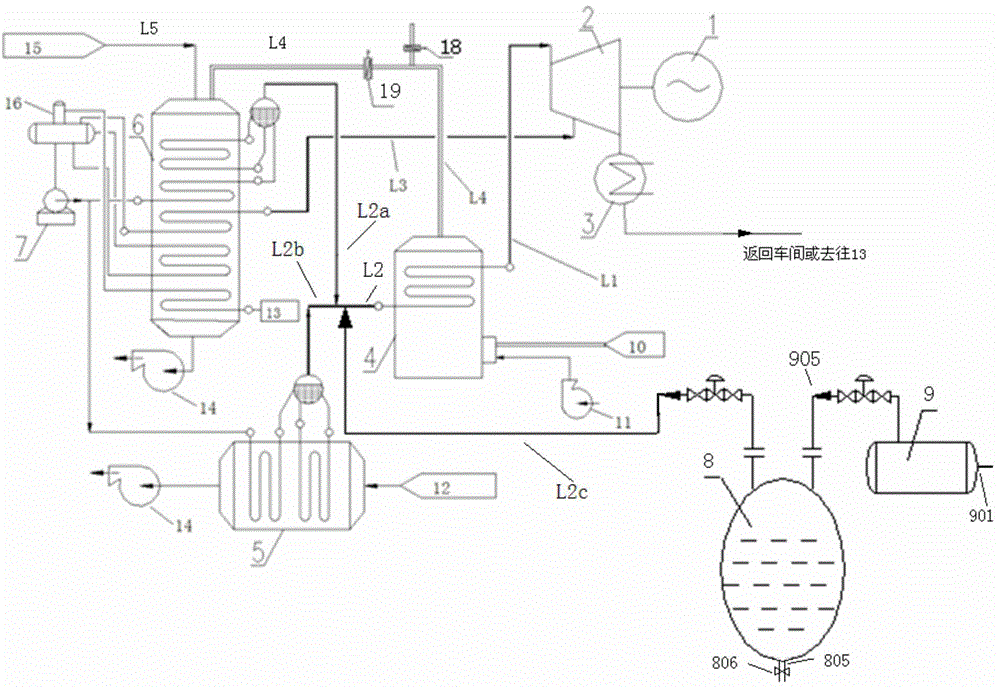

Embodiment 1

[0231] device such as figure 1 shown in . A coal gas, converter steam and sintering waste heat combined power generation device, the device includes a generator 1, a steam turbine 2, a condenser 3, a superheated afterburning furnace 4, a sintering smoke exhaust pipe waste heat boiler 5, an annular cooler waste heat boiler 6, a refinery A steel converter steam drum 9 and a converter steam regenerator 8 connected to the steelmaking converter steam drum 9 . Wherein: the low-parameter superheated steam outlet 60402 of the waste heat boiler 6 of the annular cooler is connected to the steam inlet 202 of the steam turbine. The high-parameter saturated steam output pipe L2a of the annular cooler waste heat boiler 6, the high-parameter saturated steam output pipe L2b of the sintered exhaust pipe waste heat boiler 5, and the high-parameter saturated steam output pipe L2c of the converter steam accumulator 8 are connected to the superheated afterburning The steam inlet 402 of the furna...

Embodiment 2

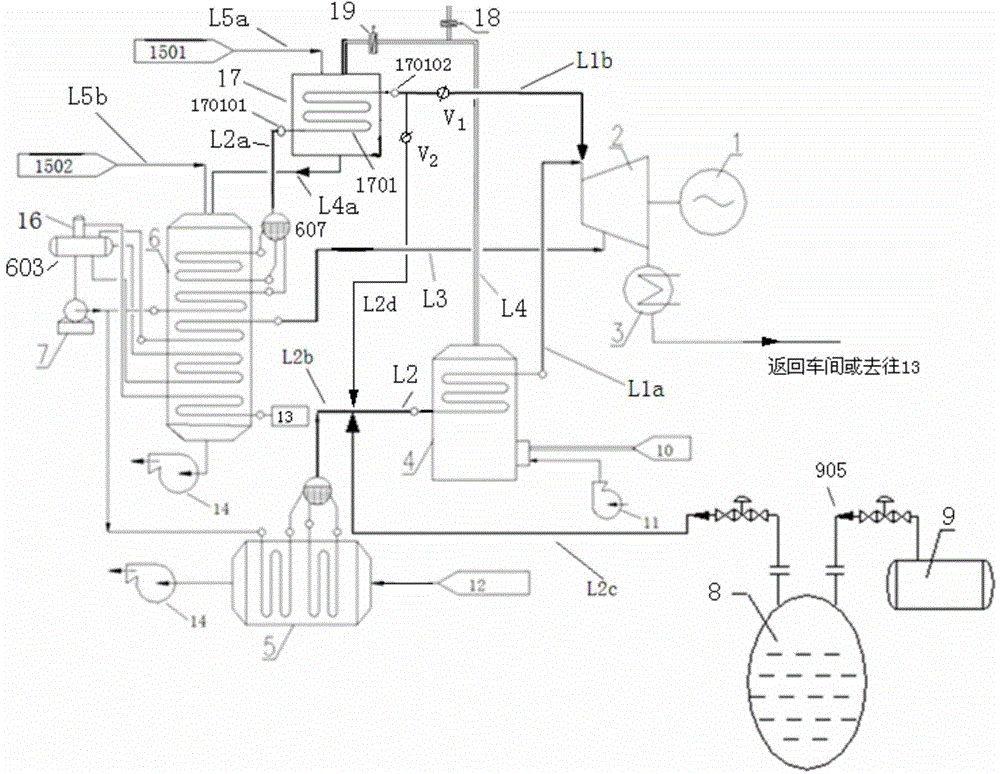

[0250] Such as figure 2 shown in . A coal gas, converter steam and sintering waste heat combined power generation device, the device includes a generator 1, a steam turbine 2, a condenser 3, a superheated afterburning furnace 4, a sintering exhaust pipe waste heat boiler 5, and a ring with an external superheating device 17 Cold machine waste heat boiler 6, steelmaking converter steam drum 9 and converter steam heat accumulator 8 connected with steelmaking converter steam drum 9. Wherein: the low-parameter superheated steam outlet 60402 of the waste heat boiler 6 of the annular cooler is connected to the steam inlet 202 of the steam turbine. The high-parameter saturated steam output pipe L2a of the waste heat boiler 6 of the annular cooler is connected to the inlet 170101 of the superheater 1701 of the external superheater 17, and is connected to the main steam inlet 201 or It is connected to the saturated steam inlet 402 of the superheated afterburning furnace through the ...

Embodiment 3

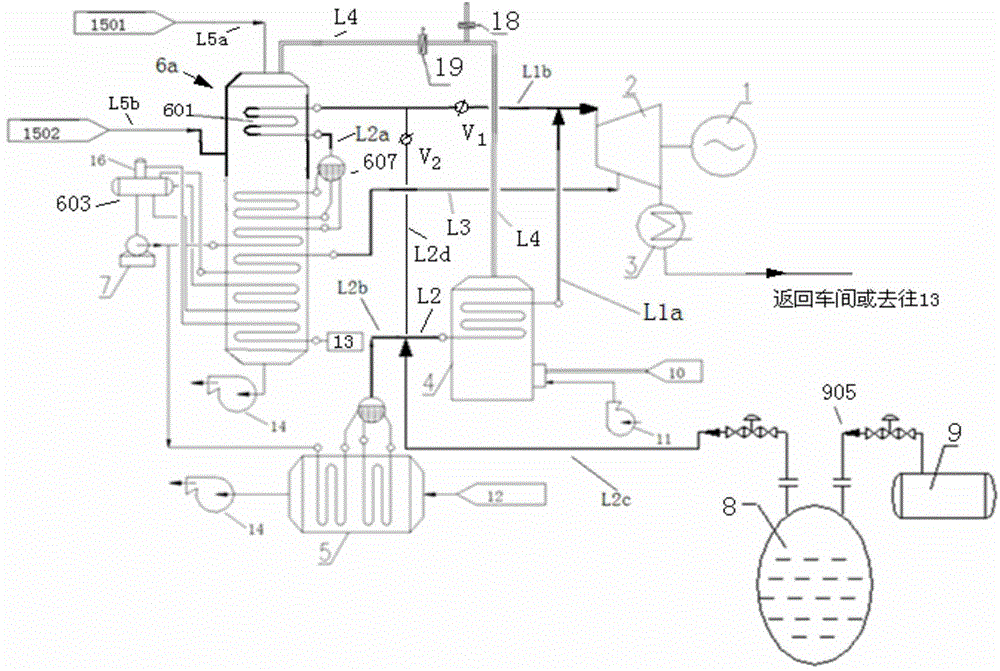

[0269] Such as image 3 shown in . A coal gas, converter steam and sintering waste heat combined power generation device, the device includes a generator 1, a steam turbine 2, a condenser 3, a superheated post-combustion furnace 4, a sintering exhaust pipe waste heat boiler 5, and a ring cooling system with a built-in superheater 610 Machine waste heat boiler 6, steelmaking converter steam drum 9 and converter steam heat accumulator 8 connected with steelmaking converter steam drum 9. Wherein: the low-parameter superheated steam outlet 60402 of the waste heat boiler 6 of the annular cooler is connected to the steam inlet 202 of the steam turbine. The high-parameter saturated steam output pipe L2a of the waste heat boiler 6 of the ring cooler is connected to the inlet 61001 of the built-in superheater 610 of the waste heat boiler of the ring cooler, and the outlet 61002 of the superheater 610 of the waste heat boiler of the ring cooler passes through the superheated steam pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com