Momordica grosvenori drying process and momordica grosvenori drying equipment

A drying process and drying equipment technology, which is applied in the fields of fruit and vegetable preservation, food preservation, food processing, etc., can solve the problems of burnt food edges, high economic costs, and small processing volume, and achieve improved structure, drying method, nutrition and aroma Does not lose, maintains the effect of color and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

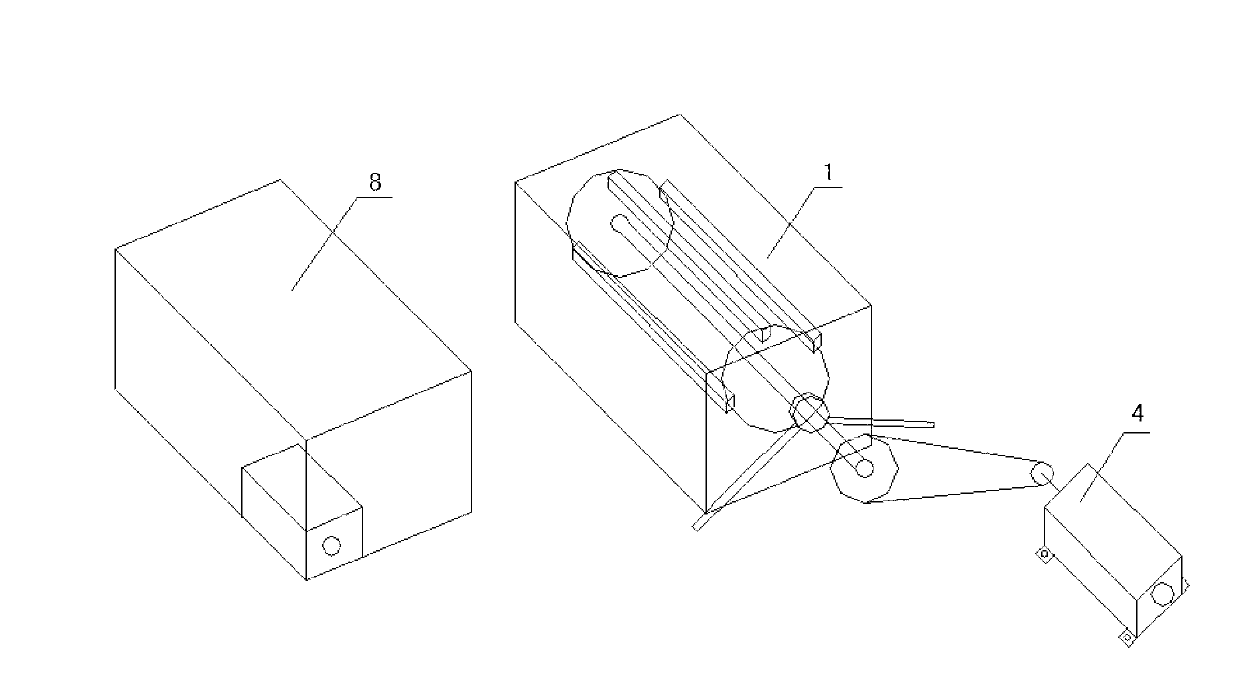

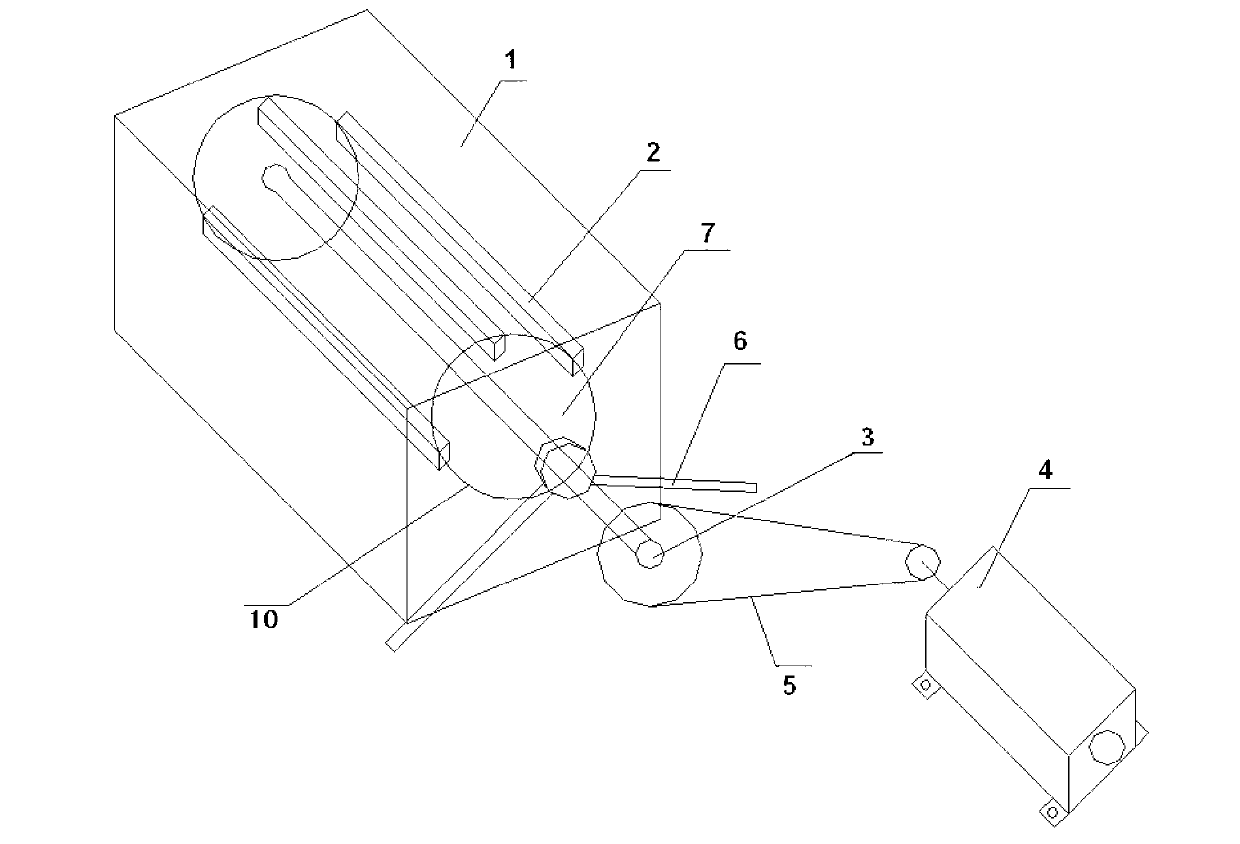

Method used

Image

Examples

Embodiment 1

[0035] (1) After washing, put a fresh Luo Han Guo into steam at 100°C for 2 to 3 minutes, then take it out and automatically lower it to normal temperature.

[0036] (2) Then make a small hole with a diameter of 1mm and a depth of 2.5cm in the center of the Luo Han Guo and the corresponding bottom, put it into a freezer at a temperature of -30~-35°C, freeze for 1.2 hours and take it out. Then put the Luo Han Guo into the material tank of the tray, set the vacuum degree in the microwave dryer to -0.078Mpa, and the temperature to 45°C, put the tray in the microwave dryer and turn on the motor, so that the motor rotates at 3-8 The speed per minute drives the tray to rotate, dehydrating and drying for 30 minutes.

[0037] (3) Then put the Luo Han Guo obtained in step 2 into the heat pump drying equipment with a temperature of 30°C and a humidity of 10%, and dry and dehydrate for 8 hours.

[0038] The improved Mangosteen process makes the processing control simple, and it is conve...

Embodiment 2

[0040] (1) Wash a fresh Luo Han Guo and put it into steam at a temperature of 95°C for 2 to 3 minutes, then take it out and automatically lower it to room temperature.

[0041] (2) Then cut the grosvenor fruit in half at the top of the pedicle, put it in a freezer at a temperature of -30~-35°C, freeze it for 1 hour and take it out, then put the grosvenor fruit into the material tank of the tray, set The vacuum degree in the microwave dryer is -0.068Mpa and the temperature is 30°C. Put the tray in the microwave dryer and turn on the motor, so that the motor drives the tray to rotate at a speed of 3-8 rpm, and dehydrate and dry for 25 minutes.

[0042] (3) Then put the Luo Han Guo obtained in step 2 into the heat pump drying equipment that has been set at a temperature of 30°C and a humidity of 10%, and dry and dehydrate for 7 hours.

[0043] In addition to possessing the advantages of Embodiment 1, the process has a drying time and drying temperature less than that of Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com