Biomass gasification equipment

A gasification device and biomass technology, which is used in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of waste heat, waste and pollution caused by solid waste pollution, and achieve the effect of avoiding secondary pollution problems and reducing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

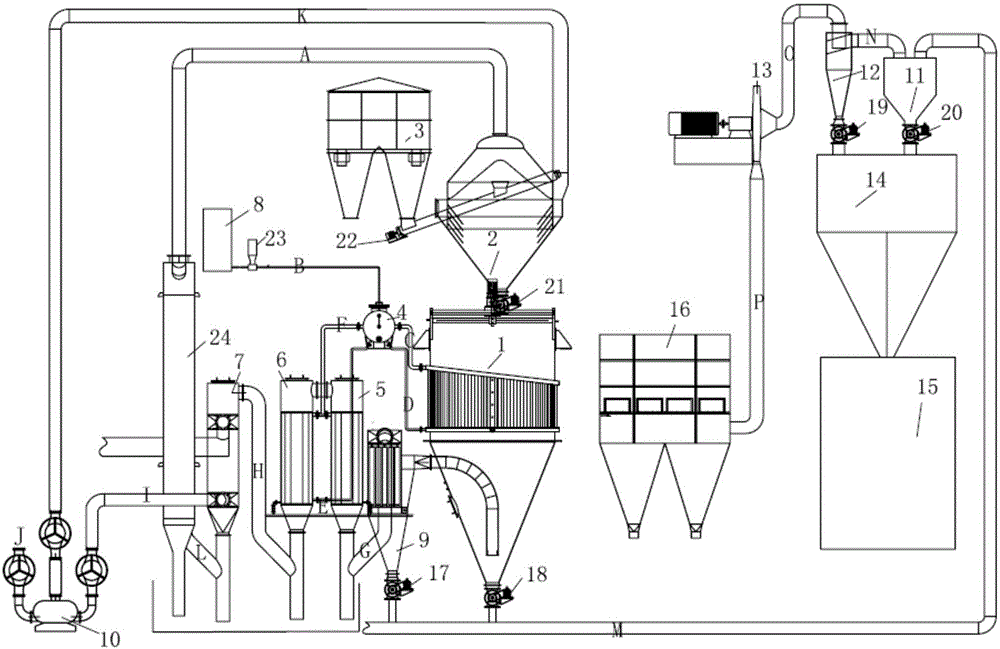

[0030] See figure 1 , figure 1 It is a schematic cross-sectional structure diagram of the biomass gasification device of the present invention. Such as figure 1 As shown, the biomass gasification device includes: a biomass gasification furnace body 1, a biomass filter 2, a biomass warehouse 3, a steam buffer tank 4, a gas-water heat exchanger (not shown), and a gas Heat exchanger 7, soft water tank 8, gold wire cloth bag dust collector 9, Roots blower 10, tar cooling intercooler 24, biomass charcoal buffer tank 11, cyclone dust collector 12, biomass charcoal bin 14 and automatic packaging System 15.

[0031] The top end of the biomass gasification furnace body 1 is connected to the bottom end of the biomass filter 2, and the top end of the biomass filter 2 is connected to the tar cooling intercooler 24 through a first pipe A. In one embodiment, the biomass gasification device further includes a first air shutter 21, which is arranged on the top of the biomass gasifier body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com