Radiant waste-heat steam generator for tunnel brick kiln

A waste heat steam, tunnel-type technology, applied in steam generation, steam generation devices, waste heat treatment, etc., can solve the problems of wasting high-temperature heat, unfavorable continuous production of brick kilns, and slow cooling speed, so as to improve cooling speed and increase economic income , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

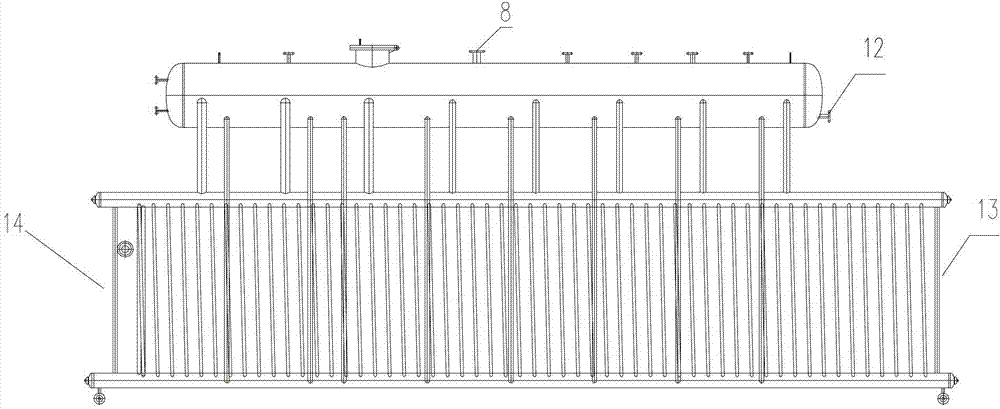

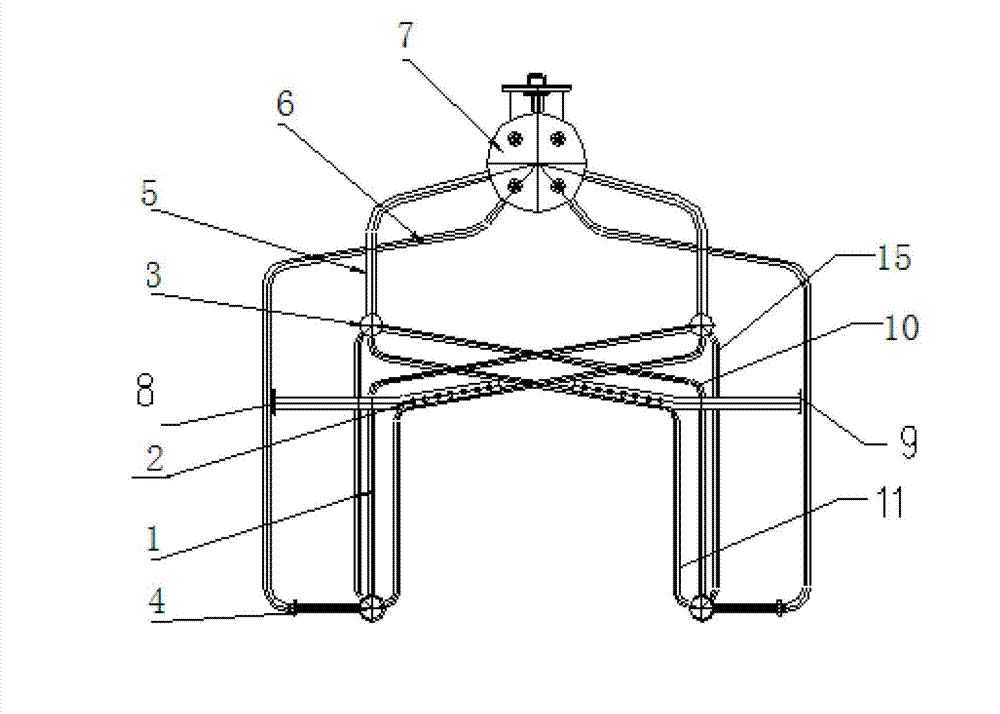

[0011] Such as figure 1 Shown in , 2: a tunnel-type brick kiln radiant waste heat steam generator, composed of radiant evaporation tube bundle 1, radiant superheated tube bundle 2, rising header pipe 3, descending header pipe 4, rising pipe 5, descending pipe 6 and The steam accumulator 7 forms. A plurality of radiant evaporating tube bundles and a plurality of radiant superheating tube bundles form a heat exchange surface, and the radiant evaporating tube bundles and radiant superheating tube bundles are arranged alternately. The inlet and outlet of the inlet and outlet are respectively connected to one end of the ascending header pipe and the descending header pipe, and the other end of the ascending header pipe and the descending header pipe are connected to the steam collector to form a circulation loop of the water system; the radiant superheated tube bundle The inlet is connected to the steam outlet 8 of the steam collector, and the outlet 9 of the radiant superheated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com