Header of 620-DEG C steam parameter ultra supercritical unit boiler

A technology of ultra-supercritical units and steam parameters, which is applied in the direction of boiler drum/box header, etc., and can solve the problems of unsatisfactory operation safety and reliability of the boiler outlet header

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

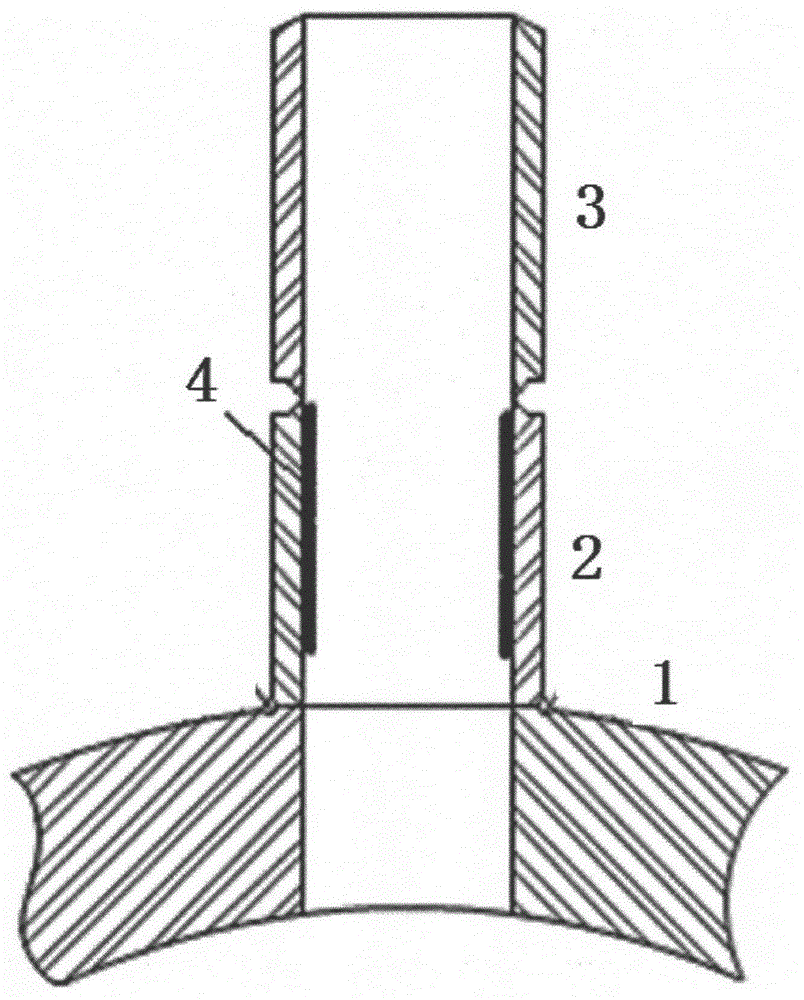

[0015] The invention provides a new type of superheater outlet header or reheater outlet header used in an ultra-supercritical unit with steam parameters exceeding 620°C. The material uses 9Cr-3W-3Co large-diameter pipes and small-diameter pipes. Such as figure 1 As shown, including the outlet header of the final superheater or the outlet header 1 of the final reheater, the material is 9Cr-3W-3Co large-diameter tube; the header base 2 is made of 9Cr-3W-3Co small-diameter tube, The inner diameter of the header pipe seat 2 is greater than 35mm, and the inner wall of the header pipe seat 2 is surfacing welded with nickel-based alloy 4 except for the area 15-20mm away from the outlet header of the final superheater or the outlet header 1 of the final reheater. ; The tube 3 of the final stage superheater or final stage reheater is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com