Pressurized water reactor compact steam generator

A technology for steam generators and reactors, which is applied to the primary side of steam generators, reactors, nuclear reactors, etc., and can solve problems such as size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

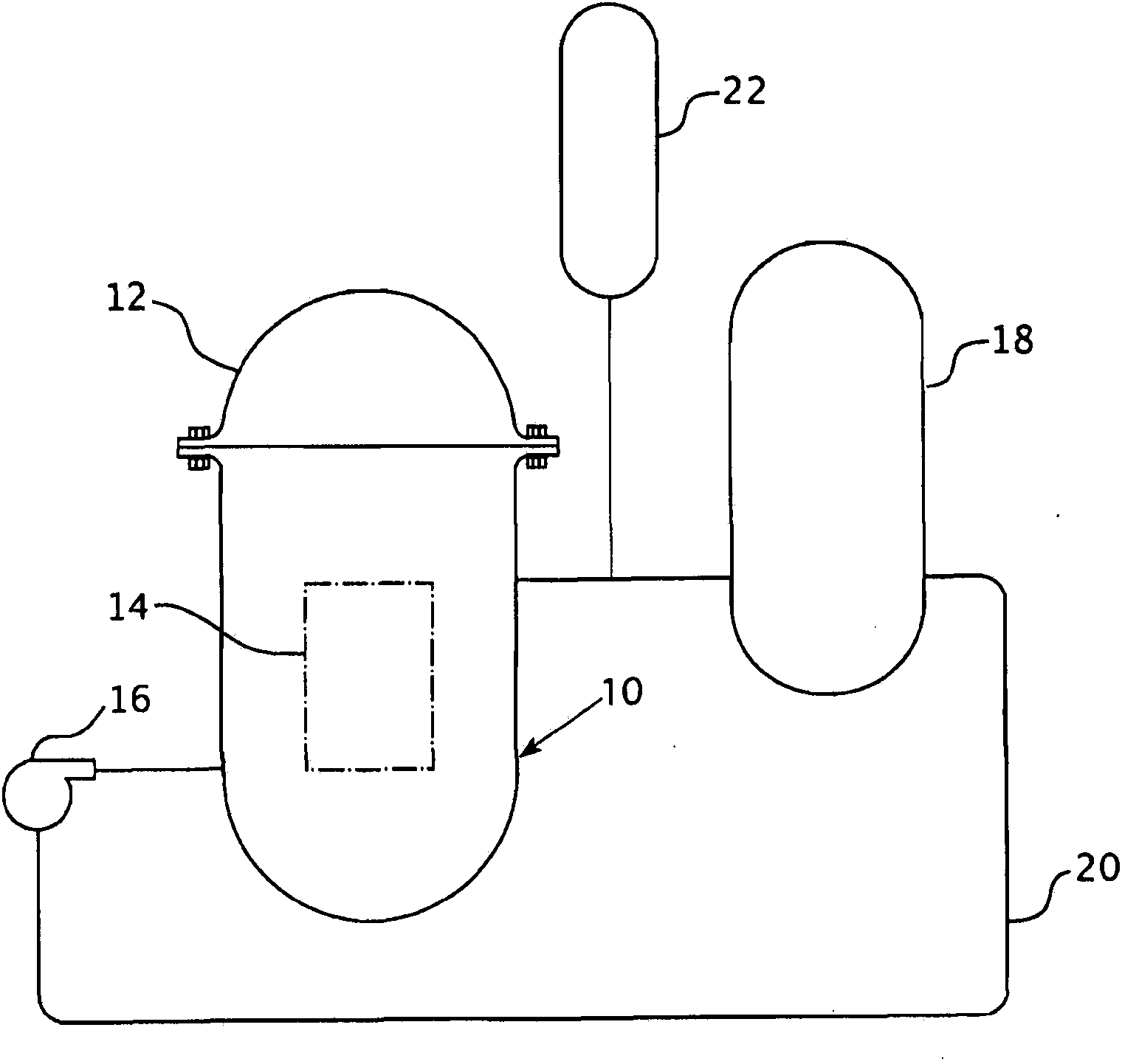

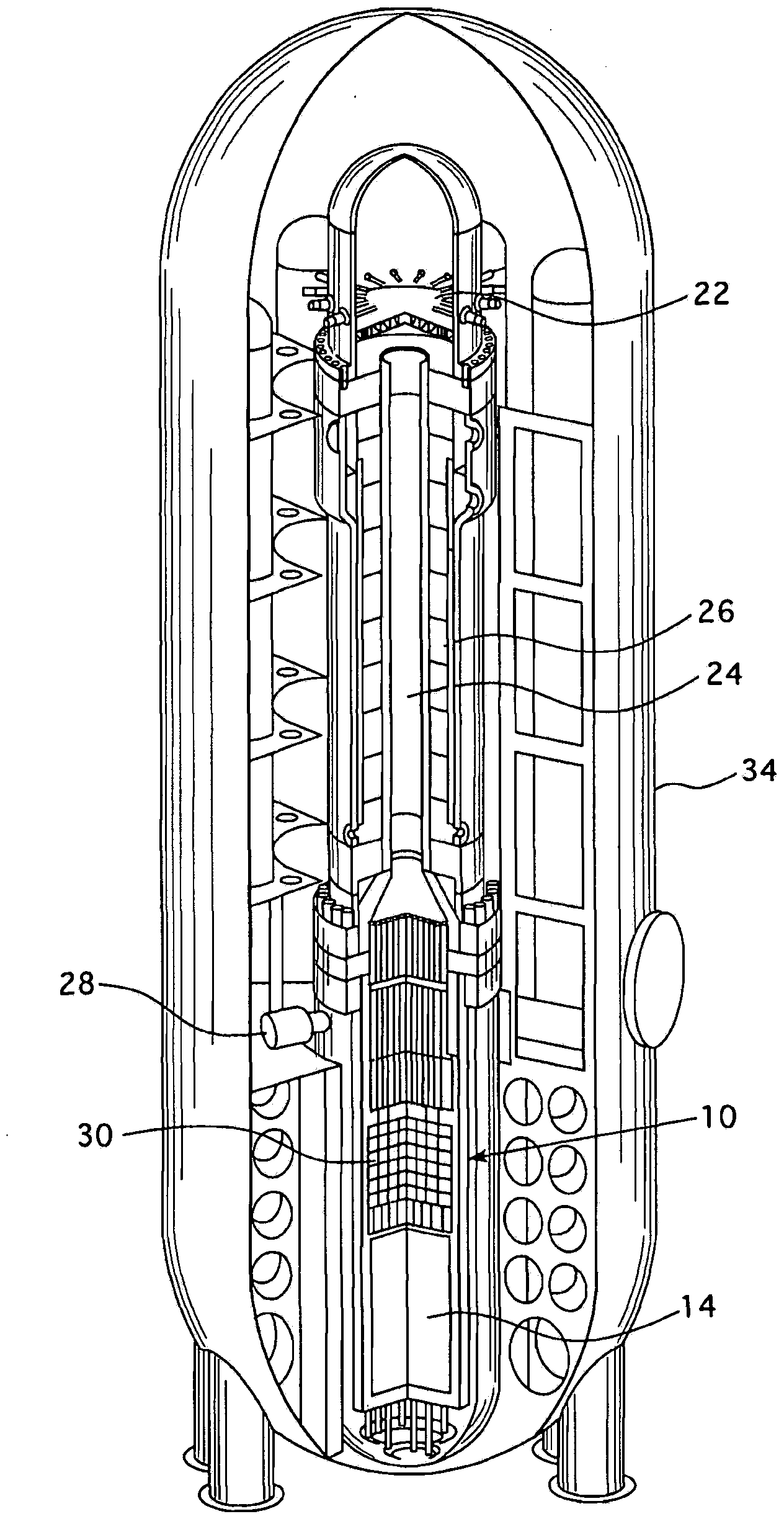

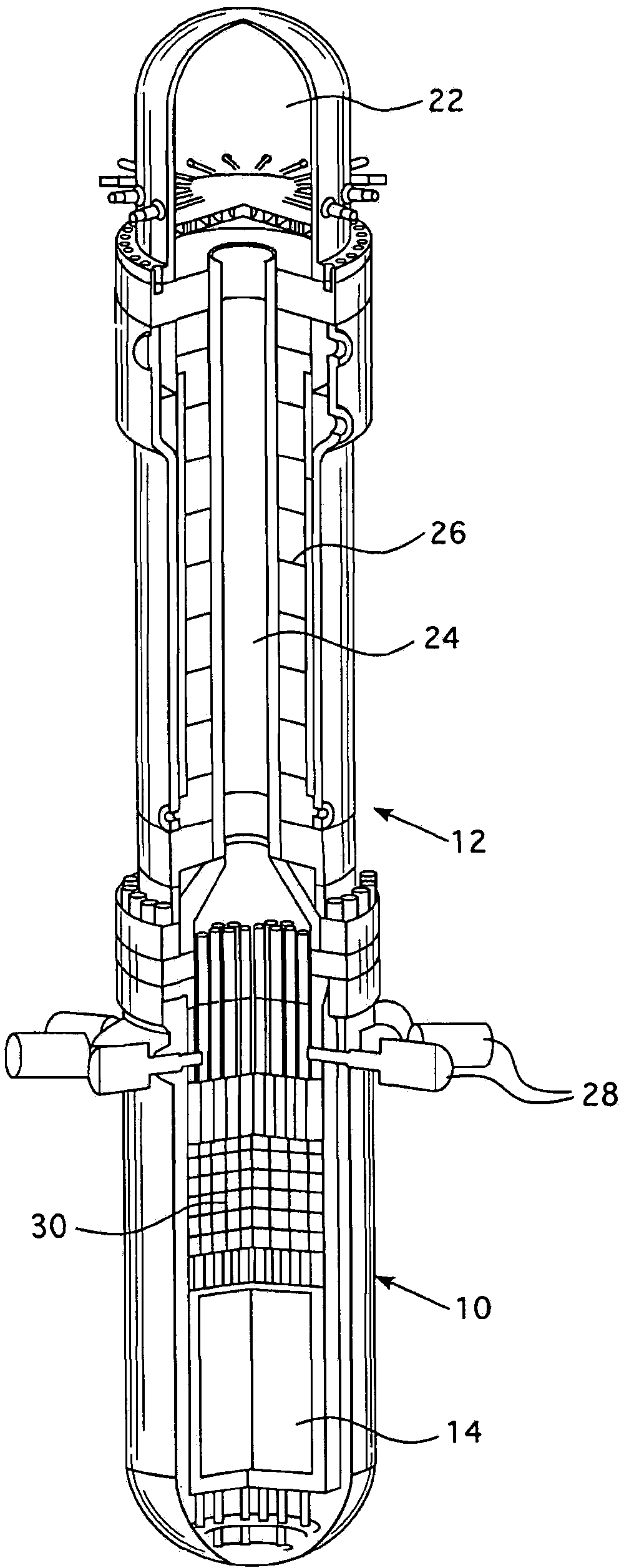

[0017] exist Figure 2-4 The embodiments of the hereafter claimed invention shown in describe a steam generator system for a pressurized water nuclear reactor employing a steam drum and recirculation loop piping external to the reactor containment vessel. The present invention changes the layout of the recirculation steam generator of a typical pressurized water nuclear reactor by relocating the functions of steam separation and feedwater preheating outside the containment vessel. Like reference numerals are used throughout the several drawings to designate corresponding parts. The steam generator system design and thermal-hydraulic conditions are selected to minimize the size of the steam generator component volume inside the containment. External vapor drum components can be isolated as needed during accident conditions and used as a secondary fluid inventory source for increased decay heat removal capability and tolerance to loss of feedwater events. The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com