Multifunctional header assembly frame

An assembly frame, multi-functional technology, applied in steam boiler accessories, workpiece clamping devices, boiler drum/box header, etc., can solve the inconvenience of the production process, the large size of the enclosed frame space, and the distance between adjacent pipes. To avoid problems such as tight gaps, to prevent dumping and ensure assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

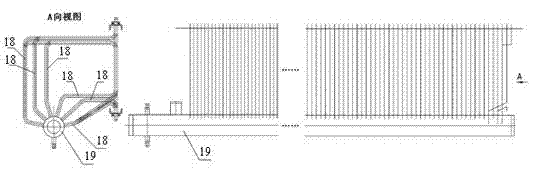

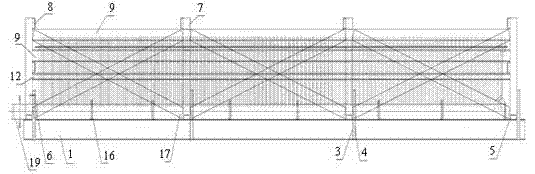

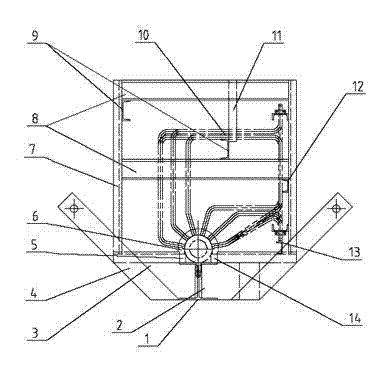

[0044] Cooperate see figure 2 , image 3 As shown, the header assembly frame of the present invention is especially suitable for the assembly of the long pipe joint 18 and the header body 19 of the special frame structure in the boiler header. The assembly frame includes lined steel and a number of handcuff plates that are arranged in conjunction with each other, and it fixes and supports the header body 19 during the assembly process; it also includes several peripheral frames arranged at intervals in the length direction of the header, and fixes the support frame during the assembly process. Some long pipe joints 18 of type structure; The said lining section steel is in the notch position opened at the bottom of said several peripheral frames.

[0045] Specifically, see Figure 2 to Figure 6 As shown, the lined steel is an H-shaped steel 1 pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com