Fused salt steam generator

A steam generator and steam technology, which is applied in the direction of steam generation, steam generation method using heat carrier, steam boiler, etc., to achieve the effect of large passage space, gentle phase transition temperature, and reduced pump consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

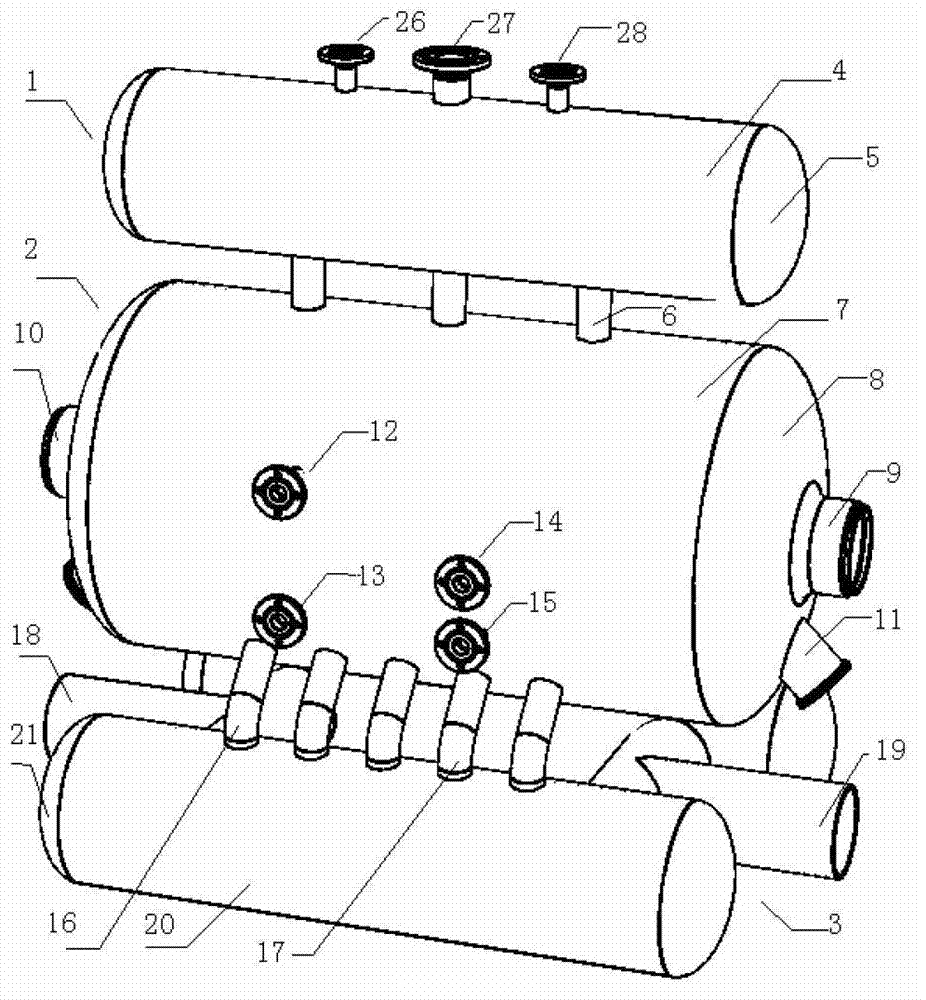

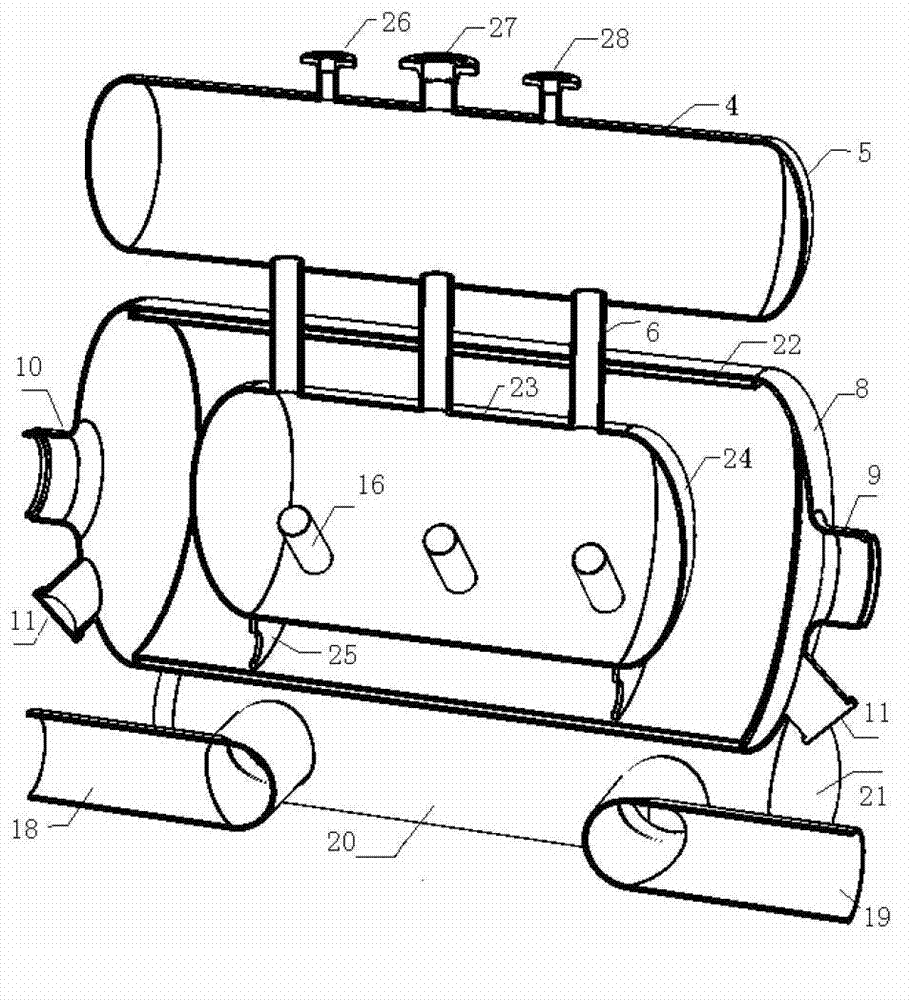

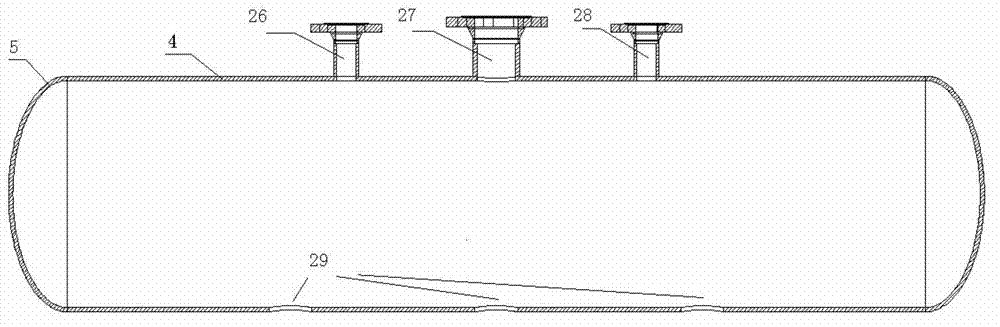

[0041] figure 1 It is a schematic isometric view of the overall structure of the present invention, figure 2 It is a sectional view of the overall structure of the present invention. The molten salt steam generator of the present invention is composed of three parts: a steam drum 1 , a steam generating tank 2 and a lower header 3 . The steam drum 1 is composed of a steam drum head 5, a steam drum shell 4, a steam outlet 27, a pressure port 26, and a safety valve port 28; the steam drum head 5 is located at both ends of the steam drum shell 4, the steam outlet 27, the The interface 26 and the safety valve interface 28 are located on the upper part of the steam drum shell 4; the pressure interface 26 and the safety valve interface 28 are located on both sides of the steam outlet 27; Solder connection. The sectional view of the steam drum str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com