Natural circulating steam injection boiler fed with high salt-containing softened water and water circulating method

A natural circulation, high-salt technology, used in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the limitation of the application range of once-through steam injection boilers, the difficulty of meeting the water quality requirements of ordinary boilers, and the reduction of steam quality requirements, etc. problems, to achieve the effect of easy maintenance and replacement, lower processing costs, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

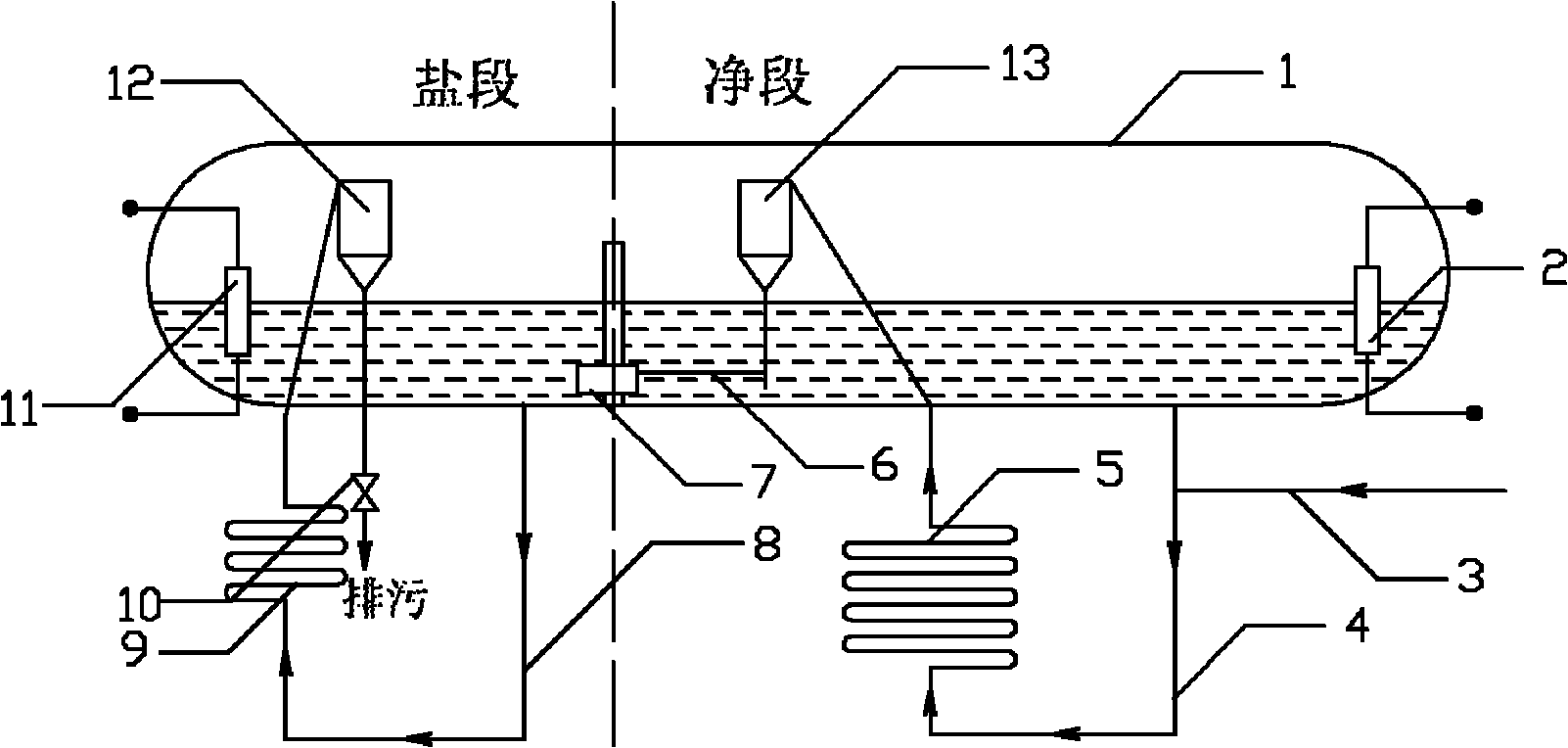

[0014] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

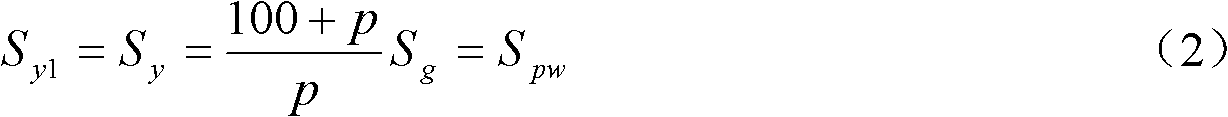

[0015] figure 1 A schematic structural diagram of a natural circulation steam injection boiler with high-salt demineralized water as feed water provided by the present invention. The boiler includes a boiler furnace, a steam drum 1, a water supply pipe 3, an economizer and a tail flue. The boiler adopts a natural Circulating drum type hydrodynamic technology and segmented evaporation technology, steam drum 1 is divided into steam drum clean section and steam drum salt section, and a clean section steam-water separation device 13 is installed in the steam drum clean section. There is a vertical descending pipe 4 in the clean section of the steam drum, the water supply pipe 3 is connected with the vertical descending pipe 4 in the clean section of the steam drum, and the vertical descending pipe in the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com