Header of ultra supercritical unit boiler in above 620 DEG C

A technology of ultra-supercritical units and headers, which is applied in the direction of boiler drums/box headers, etc., and can solve problems such as failure to meet boiler automatic adjustment performance requirements and low operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

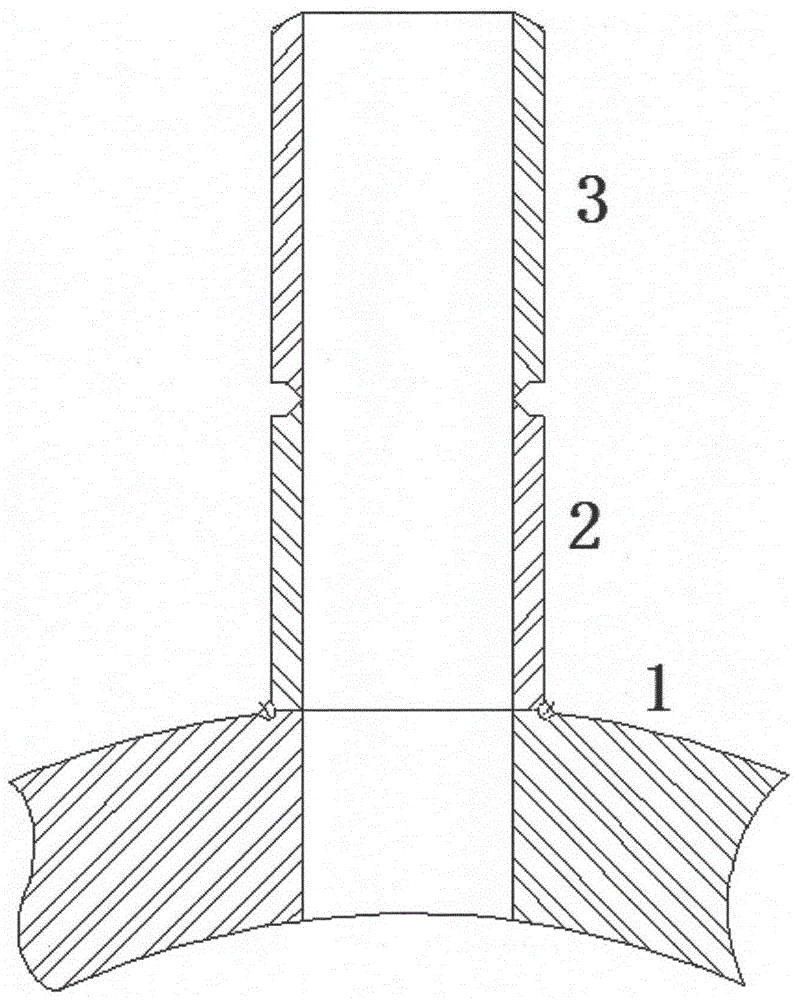

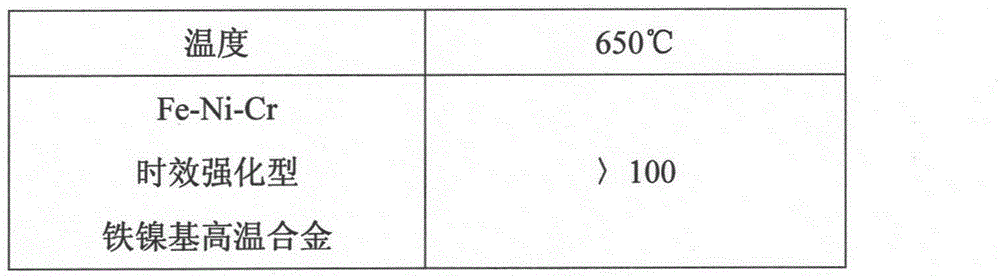

[0013] The invention provides a new type of superheater or reheater outlet header applied to super-supercritical unit boiler superheater or reheater with steam parameters exceeding 620°C. The material uses Fe-Ni-Cr aging-strengthened iron-nickel-based superalloy large-diameter tube and small caliber tube. Such as figure 1 As shown, including the outlet header of the final superheater or the outlet header 1 of the final reheater, the material is Fe-Ni-Cr aging-strengthened iron-nickel-based superalloy large-diameter tube; the header base 2 is made of Fe -Ni-Cr aging-strengthened iron-nickel-based superalloy small-diameter tube; final stage superheater or final reheater tube 3, the material is high-temperature-resistant austenitic stainless steel small-diameter tube, and the component size is calculated according to the design para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com