FeCrAl base alloy for nuclear reactor core and preparing method of alloy

A nuclear reactor and base alloy technology, applied in the field of iron-based alloy structural materials and special alloy materials, can solve the problems of high temperature oxidation resistance, toughness and high temperature resistance strength that cannot effectively meet the performance requirements of nuclear reactor cores, and achieve excellent high temperature oxidation Performance, prevention of hardening and embrittlement tendency, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

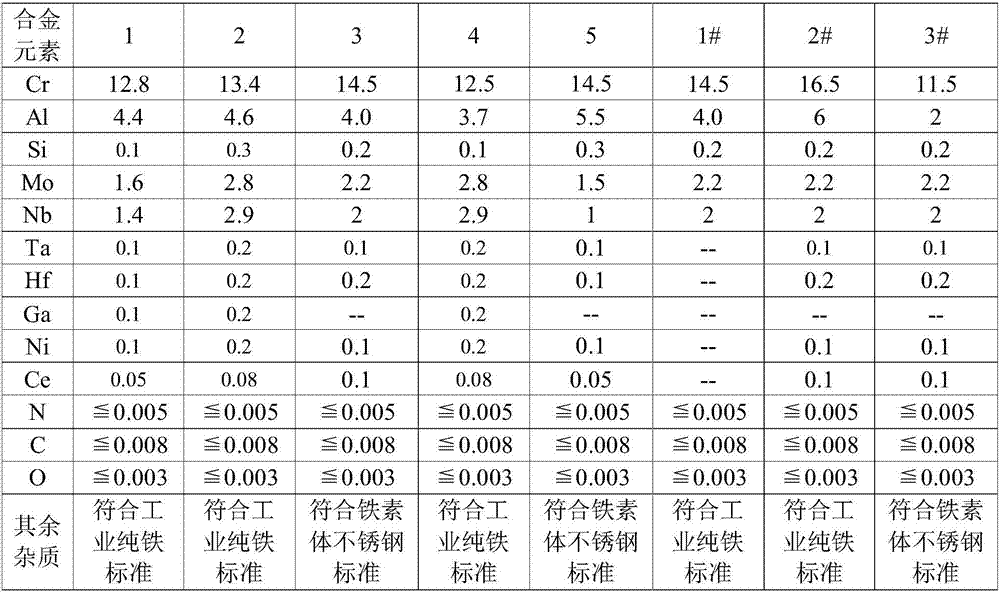

[0034] A FeCrAl-based alloy for a nuclear reactor core, the specific composition of which is shown in Table 1. In Table 1, 1 to 5 are specific proportions of the present invention, and 1# to 3# are specific proportions of alloys for comparison.

[0035] Among them, 1# is a comparative example without adding metal elements such as Ta and Hf on the basis of 3, 2# is a comparative example of increasing Cr and Al content on the basis of 3, and 3# is a comparative example of reducing Cr and Al on the basis of 3 content comparison.

[0036] Table 1

[0037]

[0038] Adopt the composition in above-mentioned table 1, adopt following method to prepare alloy, concrete preparation method is:

[0039] (1) prepare 20-30 kilograms of ingots with industrial pure iron and high-purity alloys with a purity greater than 99.9% according to the formula in Table 1;

[0040] (2) The above ingot is subjected to a high temperature homogenization annealing temperature. Annealing temperature: not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com