Header of ultra supercritical boiler unit at 700 DEG C

An ultra-supercritical unit and header technology, which is used in the components of steam boilers, boiler drum/box headers, steam boilers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

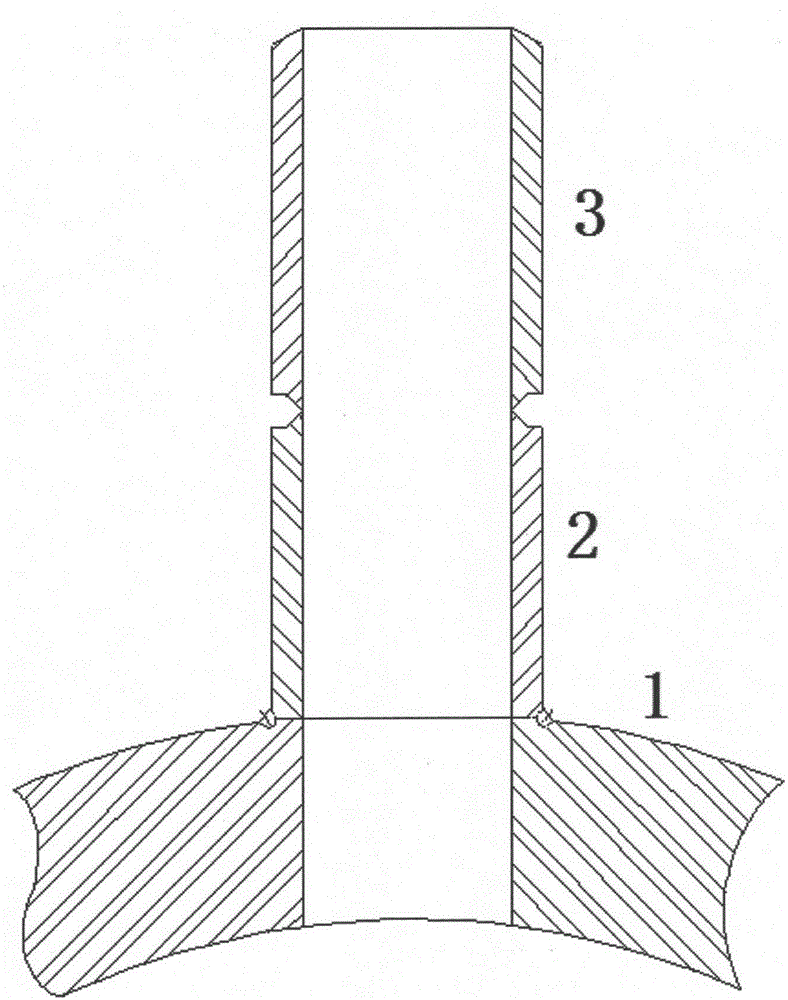

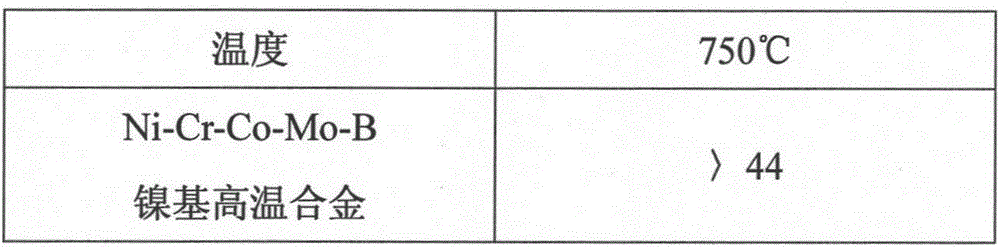

[0013] The invention provides a new superheater outlet header or reheater outlet header for ultra-supercritical units with steam parameters of 700°C. The material is Ni-Cr-Co-Mo-B iron-nickel-based superalloy large-diameter tube and small bore tubing. Such as figure 1 As shown, including the outlet header of the final superheater or the outlet header 1 of the final reheater, the material is Ni-Cr-Co-Mo-B nickel-based superalloy large-diameter tube; the header pipe seat 2, the material is Ni -Cr-Co-Mo-B nickel-based superalloy small-diameter pipe; Cr-Ni-W-Cu high-temperature-resistant austenitic stainless steel small-diameter steel pipe 3, the component size is calculated according to the design parameters.

[0014] One end of the header socket 2 of the outlet header of the final superheater or outlet header 1 of the final reheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com