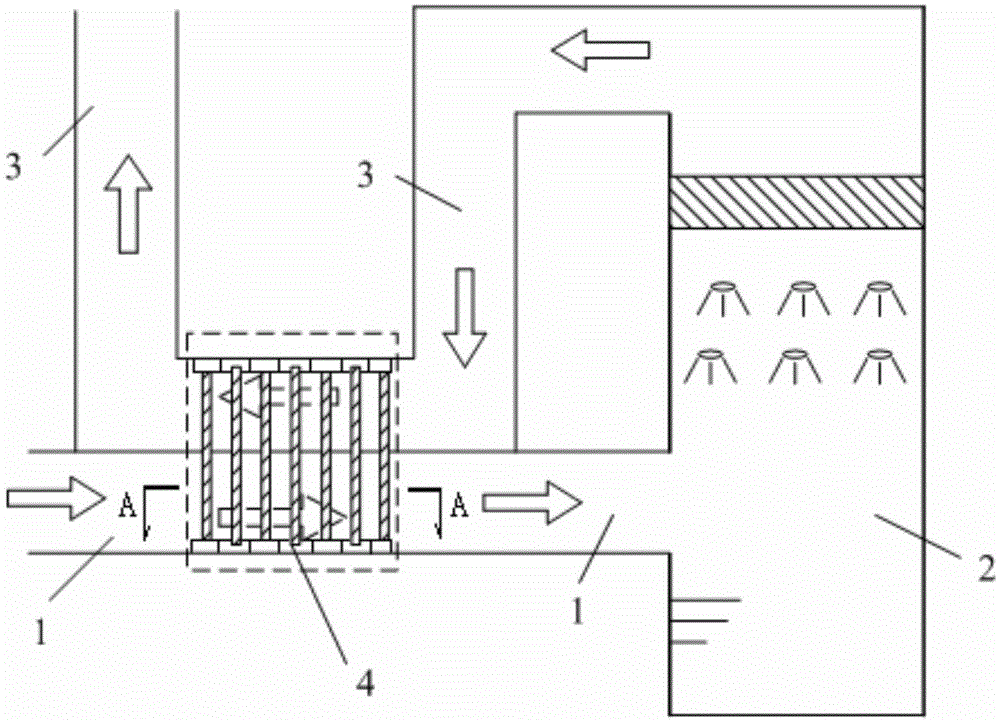

Integrated heat exchange device for wet desulphurization system

A technology of wet desulfurization and heat exchange device, applied in the field of environmental protection and wet flue gas desulfurization, can solve the problems of increasing medium circulation pipes, affecting the effect of desulfurization, increasing the amount of installation and construction, etc., to promote diffusion, improve work performance, The effect of reducing investment and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

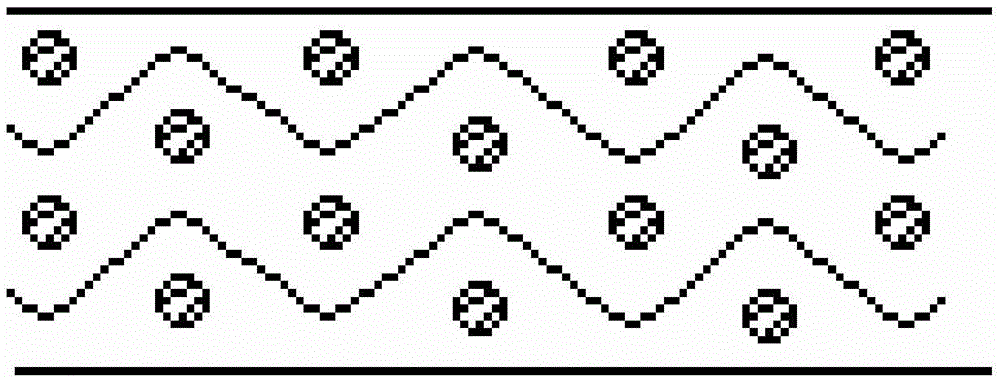

[0026] First, a brief introduction to the working principle of the heat pipe.

[0027] Heat pipe technology was previously widely used in aerospace, military and other industries. Since being introduced into the radiator manufacturing industry, people have changed the design thinking of traditional radiators and got rid of the need to rely solely on high-air-volume motors for better heat dissipation. The single heat dissipation mode and the use of heat pipe technology enable the radiator to achieve satisfactory results even with a low-speed, low-volume motor, so that the noise problem that plagues air-cooled heat dissipation can be well solved, and it has opened up a new world in the heat dissipation industry. It is now common on the radiator of the cpu.

[0028] From a thermodynamic point of view, why does a heat pipe have such a good thermal conductivity? The heat absorption and heat release of objects are relative. Whenever there is a temperature difference, the phenomenon of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com