Aerosol cooling filtration unit and low-temperature cigarette

A technology of filter unit and low-temperature cigarettes, which is applied in the fields of tobacco, smoker’s articles, applications, etc., and can solve the problems such as the unsmooth circulation of smoke, and achieve the effect of maintaining smooth flow of smoke, unobstructed longitudinal passage, and stable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The aerosol cooling filter unit of this embodiment adopts silicone resin polymethyl silicone resin to form a hollow tube by injection molding according to a conventional injection molding process. The air pressure drop generated by the hollow tube along the longitudinally extending channel is 0 Pa / mm, Further cutting to form small sections of 25 mm can obtain a cooling filter unit that can effectively reduce the temperature of the airflow.

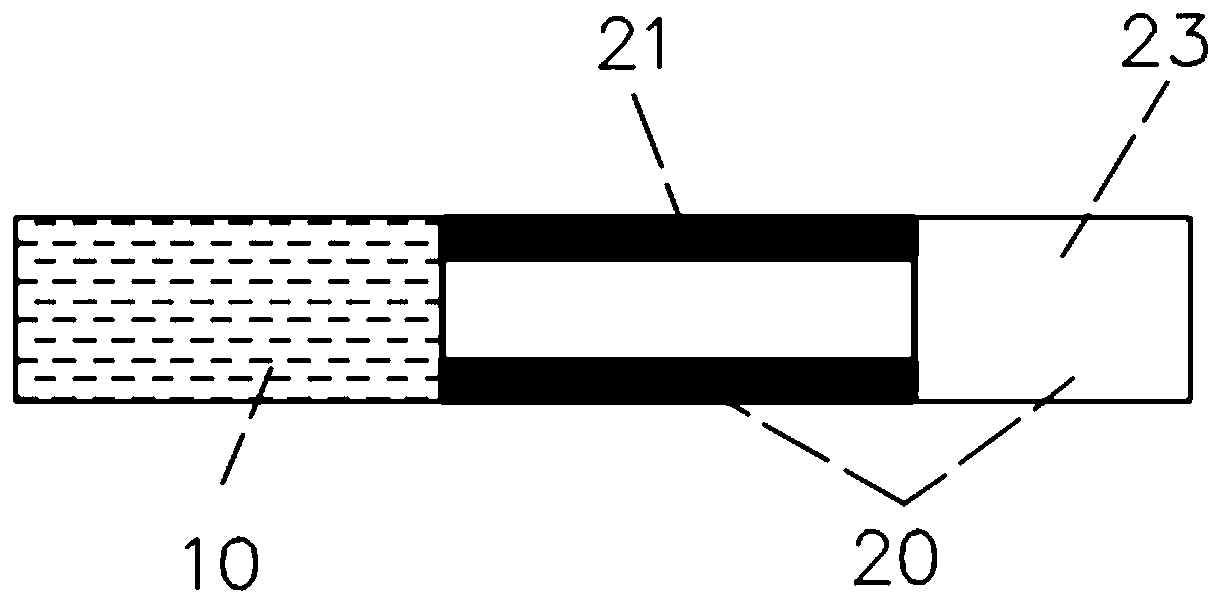

[0035] The low-temperature filter unit of this embodiment is used to prepare low-temperature cigarettes with binary filters according to the existing technology, such as figure 1 As shown, the low-temperature cigarette of this embodiment includes an aerosol generating section 10 and a filter section 20, and the filter section 20 further includes an upstream filter section 21 and a mouth-end filter section 23, and the upstream filter section 21 is the cooling filter section of this embodiment. unit.

[0036] The upstream filter sect...

Embodiment 2

[0041] The aerosol cooling filter unit of this embodiment uses silicone rubber methyl vinyl silicone rubber to make a silicone rubber sheet according to a conventional process, and the silicone rubber sheet is embossed or folded or gathered to form a uniform strip with multiple channels in the longitudinal direction Rod, cut the rod to obtain a cylinder with a porous cut surface and a length of 144mm, or cut the silicone rubber sheet into a cylinder with a width of 144mm, and then gather it to form a cylinder with a longitudinal multi-channel structure, that is, to obtain this embodiment. Example aerosol cooling filter unit.

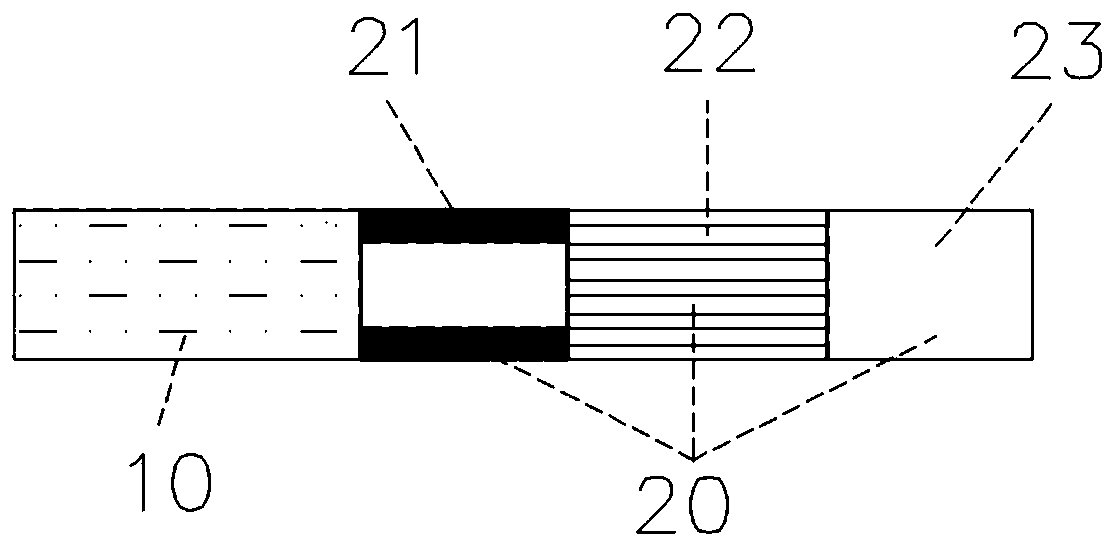

[0042] After measurement, the air pressure drop produced by the cooling filter unit along the longitudinally extending channel is 0.4 Pa / mm, and then further cut to form a small section with a length of 6mm, and the small section is prepared according to the existing technology. Three-element filter low-temperature cigarettes, such as figure 2 shown. T...

Embodiment 3

[0047] The aerosol cooling filter unit of the present embodiment is specifically as follows, take a roll paper material with a width of 106mm, evenly smear, spray, and print fluid organic silicone resin polyaryl silicone resin on the roll paper material, and then use it at 50 ~ Dry and solidify at 100°C to prepare a silicone composite film. The silicone composite film is embossed or folded or gathered to form a continuous cylindrical strip with multiple longitudinal channels and uniformity. The cylindrical strip is cut to obtain a porous cut surface and a length of A cylinder of 144 mm can also be formed by cutting the organosilicon composite film into a width of 144 mm, and then gathering to form a cylinder with a longitudinal multi-channel structure, that is, the aerosol cooling filter unit of this embodiment is obtained.

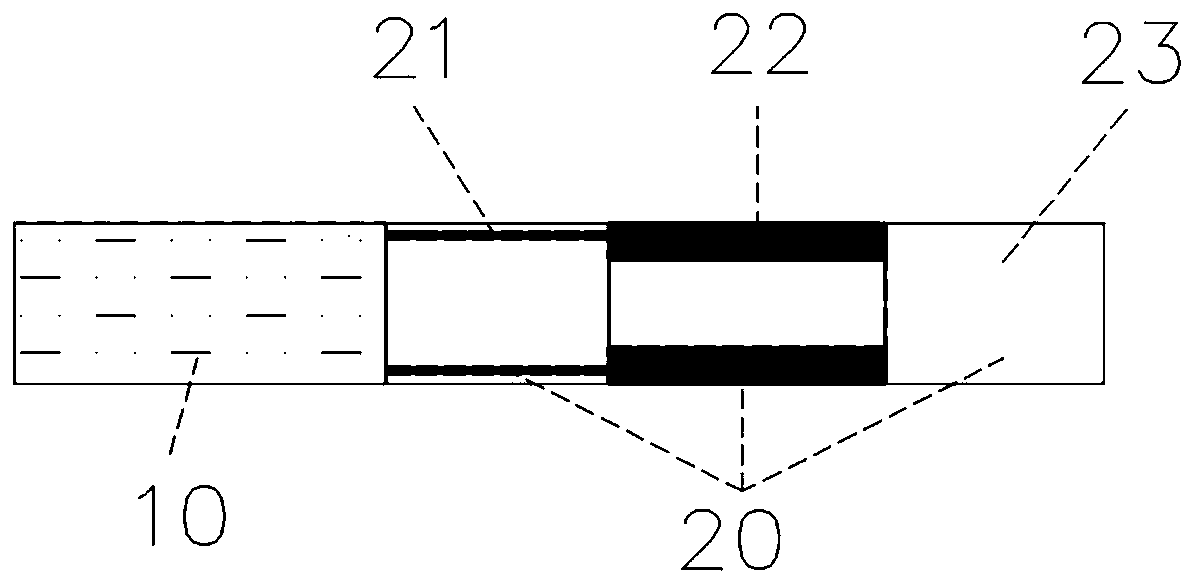

[0048] After measurement, the air pressure drop produced by the cooling filter unit along the longitudinally extending channel is 0.5 Pa / mm, and then furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com