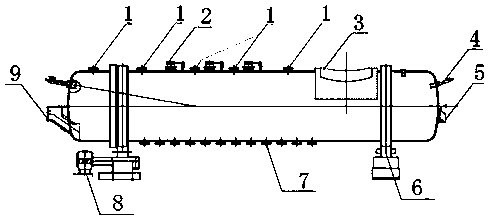

Top and bottom composite blowing molten bath smelting technology and device

A top-bottom combined blowing and molten pool smelting technology, which is applied in the direction of rotary drum furnace, crucible furnace, furnace, etc., can solve the problems of aggravating coking in the flue, easy bonding of the feeding port and the flue port, and melt splashing, etc., to achieve Relieving the coking condition, reducing the flue gas temperature, and reducing the effect of melt splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The smelting temperature is 1200°C; the flux is quartz stone, and its addition amount is 8% of the total weight of copper ore; the gas supplied to the bottom is oxygen and air, and the concentration of the mixed gas is 75%, and its addition amount is 120Nm3O2 per ton of copper ore; The gas supplied to the top is oxygen, and the amount added is 20Nm3O2 per ton of copper ore;

[0038] Processing results: the top-bottom compound blowing smelting furnace processed a mixed charge of 70t / h (dry basis), and the mixed charge contained 22.5% copper; the smelting output copper matte was 21t / h, containing 70% copper, and the smelting slag was 38t / h, containing copper 2.4%. The direct copper recovery rate in the smelting process is about 93%.

Embodiment 2

[0040] The smelting temperature is 1220°C; the flux is quartz stone, and its addition amount is 8% of the total weight of copper ore; the gas supplied to the bottom is oxygen and air, and the concentration of the mixed gas is 73%, and its addition amount is 110Nm3O2 per ton of copper ore; The gas supplied to the top is oxygen, and the amount added is 30Nm3O2 per ton of copper ore;

[0041] Processing results: the top-bottom composite blowing smelting furnace processes a mixed charge of 200t / h (dry basis), and the mixed charge contains 22.3% copper; the smelting output copper matte is 56t / h, containing 75% copper, and the smelting slag is 110t / h, containing copper 1.9%. The direct copper recovery rate in the smelting process is about 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com