Device and method for promoting double-tower double-cycle wet desulfurization system to remove fine particulate matters and sulfur trioxide acid mist

A wet desulfurization and fine particle technology, applied in the field of dust removal, can solve the problems of difficult operation and complicated device, and achieve the effect of promoting removal, simple process and improving removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

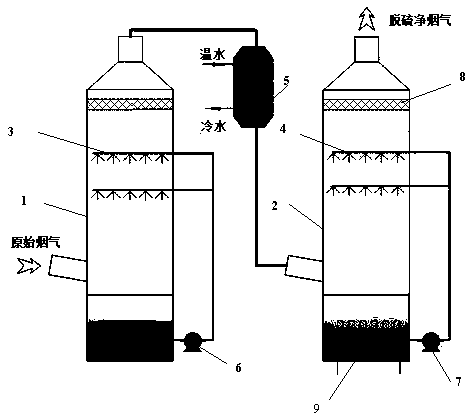

[0021] like figure 1 As shown, a double-tower double-circulation wet desulfurization device of the present invention promotes the efficient removal of fine particles and sulfuric acid mist in flue gas, mainly including pre-washing tower 1, desulfurization tower 2, flue gas heat exchanger 5, The pre-washing tower circulation pump 6 arranged on the outside of the pre-washing tower 1 and the desulfurization tower circulating pump 7 arranged on the outside of the desulfurization tower 2 are provided with a pre-washing tower liquid storage tank, a pre-washing tower, and a pre-washing tower in sequence from bottom to top. The tower inlet, pre-scrubber spraying device 3, demister and pre-scrubbing tower outlet, and the pre-scrubbing tower liquid tank, pre-scrubbing tower circulation pump 6 and pre-scrubbing tower spraying device 3 are sequentially connected through pipelines to form a pre-washing cycle circuit; the desulfurization tower is provided with a desulfurization tower liquid...

Embodiment 2

[0024] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 350Nm 3 / h, supplemented by an aerosol generator, SO 3 Add appropriate amount of coal-fired fly ash, SO 3 , water vapor, so that the concentration of fine particles in the coal-fired flue gas is 48.4 mg / Nm 3 , the mass concentration of fine particulate matter is 15.2mg / Nm 3 , the fine particle number concentration is 3.6×10 6 1 / cm, SO 3 The concentration is 60 mg / Nm 3 . The system adopts the device and its removal method described in Example 1. The wet desulfurization tower adopts a spray tower with a tower diameter of 219mm and a tower height of 5250mm, and a high-efficiency demister is installed on the top of the spray tower. The dust-laden flue gas with a temperature of 120°C first enters the pre-washing tower and reacts with the pre-washing liquid at a temperature of 50°C to reduce the temperature of the flue gas to 55°C, increase the humidity to 95%, and the SO in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com