Heating surface of high-temperature high-pressure natural circulating dry coke quenching residual heat boiler

A waste heat boiler and natural circulation technology, which is used in coke ovens, coke cooling, petroleum industry, etc., can solve problems such as affecting the safety of boilers, water circulation failures, and no slag condensing pipes, so as to improve the safety of water circulation and ensure operation. Safety, effect of simplifying pipeline structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings and embodiments.

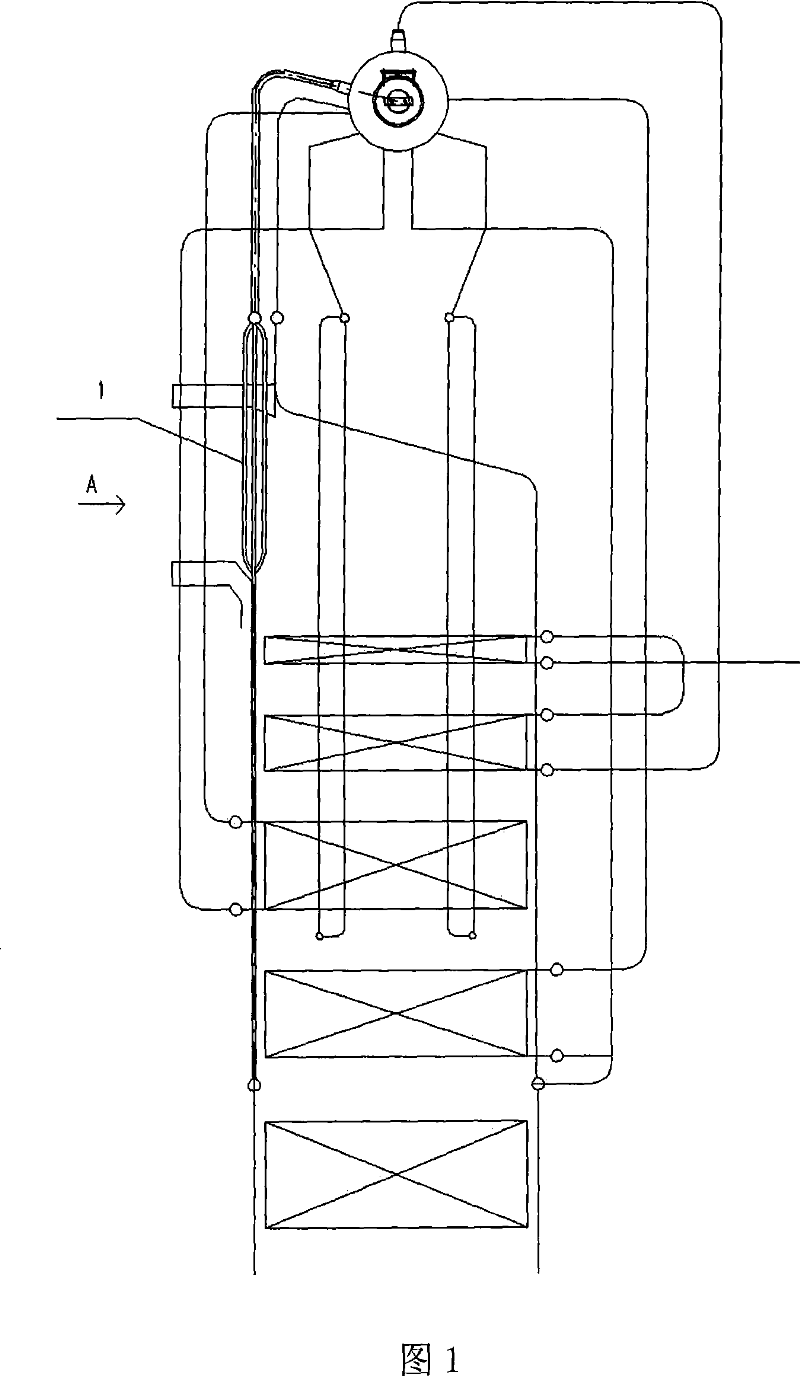

[0016] As shown in Figure 1, the heating surface of the high-temperature and high-pressure natural circulation dry quenching waste heat boiler of the present invention is formed by the tube bundle of the front wall water-cooled wall at the inlet of the boiler to form a slag tube 1 and lead to the boiler ceiling for Improve the heat absorption of the water wall of the front wall and the safety of the water circulation of the water wall of the front wall. The slag tube 1 in the combustion chamber at the inlet of the waste heat boiler is made of a metal spraying anti-wear tube.

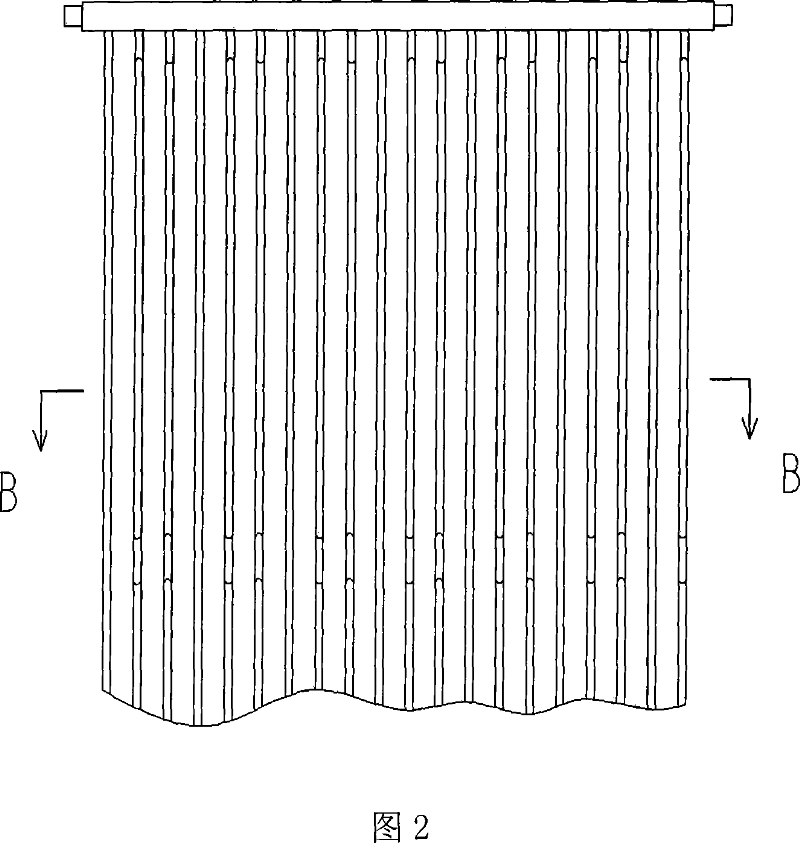

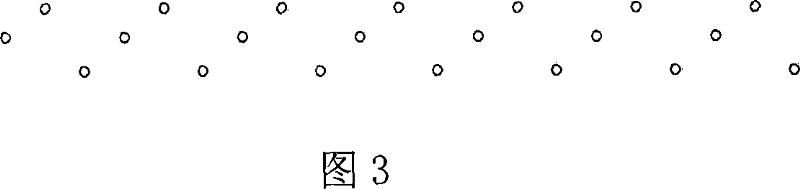

[0017] As shown in Figures 2 and 3, the slag tube 1 of the present invention is arranged in staggered rows. Generally, the number of rows is not more than 5 rows. 1 / d, s 2 / d) Larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com