Flue gas waste heat utilization system of thermal power plant

A flue gas waste heat and thermal power plant technology, applied in the field of thermal power plants, can solve problems such as increased exhaust heat loss, changes in design coal types, untimely soot blowing of boilers, etc., to reduce power consumption, improve economy and feasibility, Effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

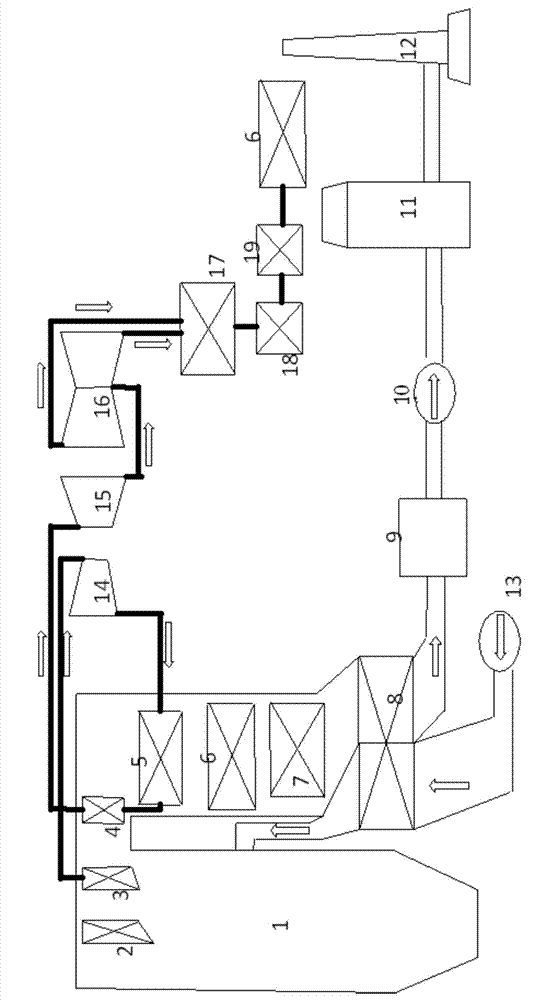

[0021] figure 1 Shown is a schematic structural diagram of a thermal power plant power generation system in the prior art. Fuel such as pulverized coal is carried into the furnace 1 by the primary air, and the air is delivered to the air preheater 8 through the blower 13 (the air is called air supply, and the air supply The wind includes secondary air, burn-off air, etc. Both the secondary air and the burn-off air enter the furnace after being heated by the air preheater (the two are at different positions at the entrance of the furnace), and are preheated in the air preheater 8 After heating, it enters the furnace 1 of the boiler. The pulverized coal in the furnace is burned up under the oxidation of the secondary air and the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com