System and method for recovering and utilizing waste heat of smoke after wet desulphurization

A wet desulfurization, flue gas waste heat technology, applied in the direction of heat exchanger type, climate sustainability, reduction of greenhouse gases, etc., to achieve the effects of good water quality, elimination of white smoke plumes, and improved energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

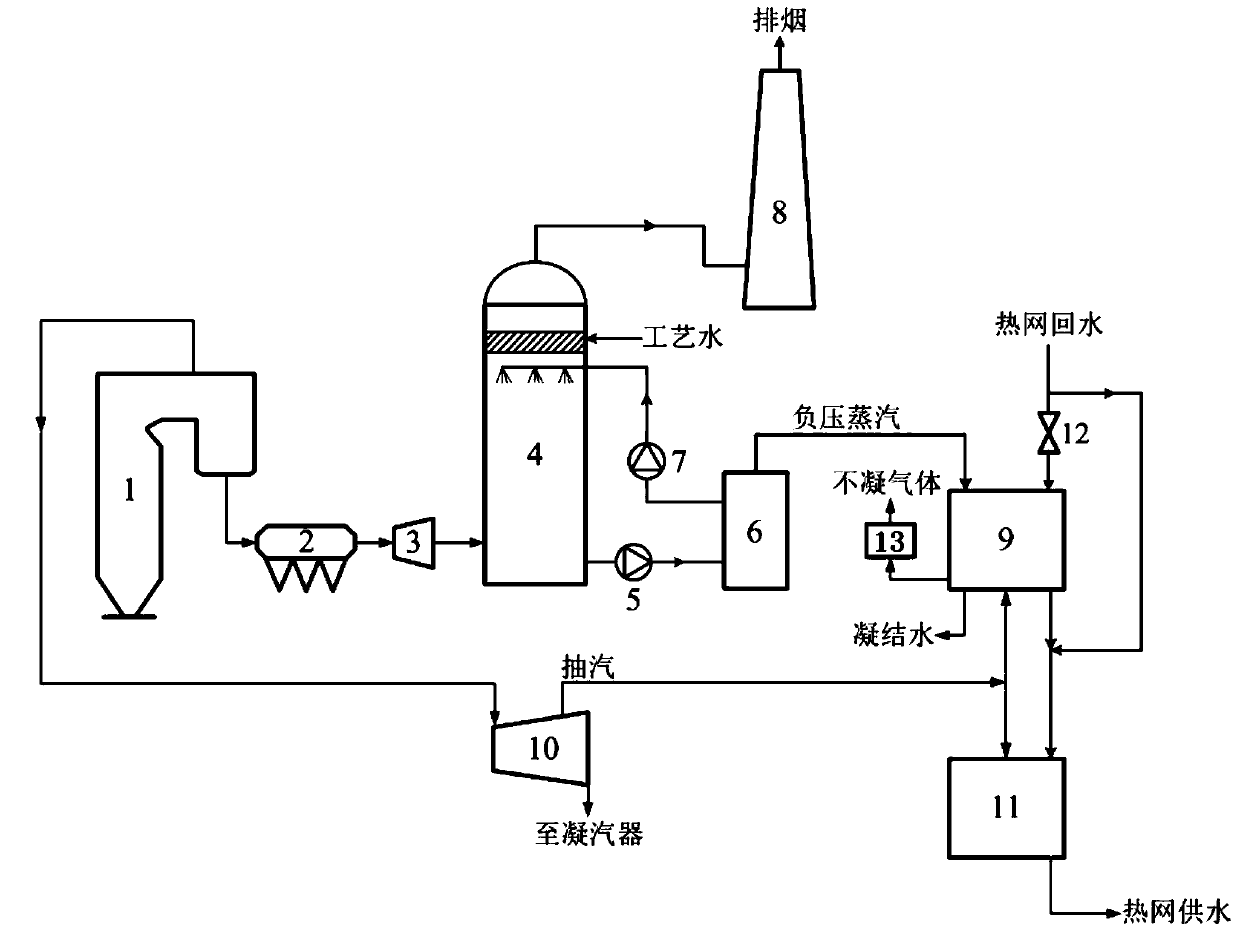

[0038] see figure 1 As shown, the present invention provides a flue gas waste heat recovery and utilization system after wet desulfurization, including a coal-fired boiler 1, a wet desulfurization tower 4, a flash tower 6, an absorption heat pump 9, a steam turbine 10 and a heat network heater 11;

[0039] The smoke outlet of the coal-fired boiler 1 is connected to the smoke inlet of the wet desulfurization tower 4;

[0040] The steam outlet of the coal-fired boiler 1 is connected to the steam inlet of the steam turbine 10;

[0041] A steam extraction port is provided in the middle of the steam turbine 10, and the steam extraction port communicates with the heat network heater 11 and the absorption heat pump 9 respectively;

[0042] The bottom outlet of the wet desulfurization tower 4 is connected to the inlet of the flash tower 6 through the first slurry pump 5, and the cold slurry outlet of the flash tower 6 is connected to the upper inlet of the wet desulfurization tower 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com