High-purity tellurium dioxide preparation method and device

A tellurium dioxide preparation device technology, applied in the direction of binary selenium/tellurium compound, selenium/tellurium oxide/hydroxide, etc., can solve the problems of affecting the environment, insufficient product purity, nitric acid residue, etc., to improve efficiency, The effect of guaranteeing purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

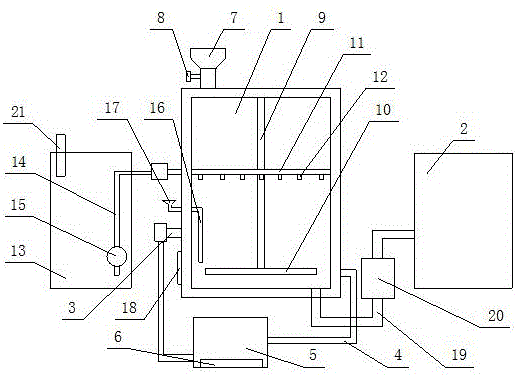

[0016] Embodiment 1: as figure 1 Shown, a kind of preparation method of high-purity tellurium dioxide comprises the following steps:

[0017] a, oxidation reaction, adopt hydrogen peroxide to oxidize 4N tellurium powder, accurately control the addition amount and the addition rate of hydrogen peroxide with flow pump 15, the liquid-solid ratio control of hydrogen peroxide and 4N tellurium powder in reaction tank 1 is 2.5-3.5:1, the concentration of hydrogen peroxide Control between 10%-25%;

[0018] b. Purification, add a purifying agent at a dose of 2g / L to the solution obtained after the oxidation reaction. The purifying agent is an organic flocculant. After adding the purifying agent, stir thoroughly, then stand still, and filter the sediment through a pipeline filter after standing ;

[0019] c. Concentrate and crystallize, send the purified solution into the concentration tank, the concentration tank adopts electric heating, and conduct high-temperature distillation on t...

Embodiment 2

[0022] Embodiment 2: Same as the above embodiment 1, wherein the reaction tank 1 is provided with a hydrogen peroxide concentration detection sensor, and the hydrogen peroxide concentration detection sensor is wirelessly connected to the flow pump 15 .

Embodiment 3

[0023] Embodiment 3: Same as the above embodiment 1, wherein a liquid level sensor is provided at the lower part of the hydrogen peroxide storage tank 13, and a liquid replenishment pipe 21 is provided at the top of the hydrogen peroxide storage tank 13.

[0024] The present invention precisely controls the dosage of hydrogen peroxide through the flow pump 1513, so that 4N tellurium powder is oxidized in hydrogen peroxide with a concentration of 10%-25%, without causing local overoxidation and ensuring the quality of the product. During the oxidation process, the stirring rod 9 Drive the stirring blade 10 to stir, so that the 4N tellurium powder is fully contacted with hydrogen peroxide. After the oxidation is completed, add the organic flocculant through the addition funnel 17 in a dose of 2g / L, then stir, and let stand to make the iron, copper, nickel, zinc, etc. The oxides of impurities are polymerized and precipitated, filtered through the pipeline filter, and discharged th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com