Mechanical grinding recovery method for cadmium telluride film solar cells

A technology for recycling and processing solar cells, which is applied in the direction of binary selenium/tellurium compounds, selenium/tellurium oxides/hydroxides, and improvement of process efficiency. The use value of glass slag is small, etc., to achieve high comprehensive utilization rate, improve material recovery rate and recovery effect, and ensure the effect of environmental friendliness throughout the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

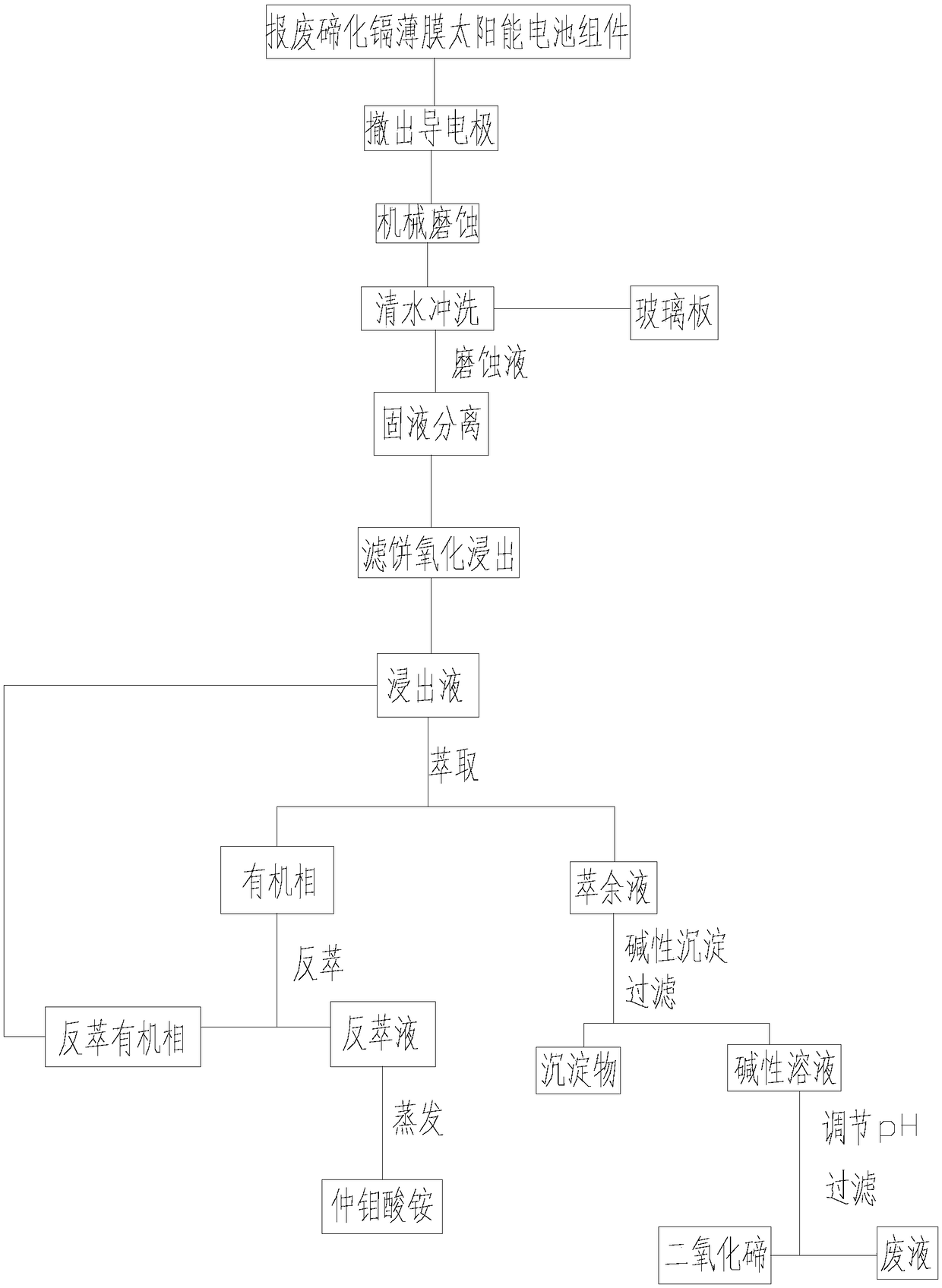

[0023] See figure 1 , The invention provides a mechanical abrasion recovery processing method for cadmium telluride thin film solar cells, including the following steps:

[0024] (1) Strip the photovoltaic film: remove the back glass and conductive electrodes of the scrapped cadmium telluride thin-film solar cell module to obtain a glass substrate with photovoltaic film, and then mechanically abrade the photovoltaic film and rinse the mechanical abrasion with water After the glass substrate, the valuable metals in the photovoltaic film layer and a small amount of solid glue all enter the water body, the washed wastewater is collected together, filtered to obtain the filter residue, and then the filter residue can be recycled thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com