Preparation method and application of ultrathin 4N tellurium dioxide powder

A technology of tellurium dioxide and powder, which is applied in the field of tellurium dioxide preparation, can solve the problems of complex production process steps of tellurium dioxide, high energy consumption, waste of chemical reagent raw materials, etc., achieve low equipment requirements and improve quality , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

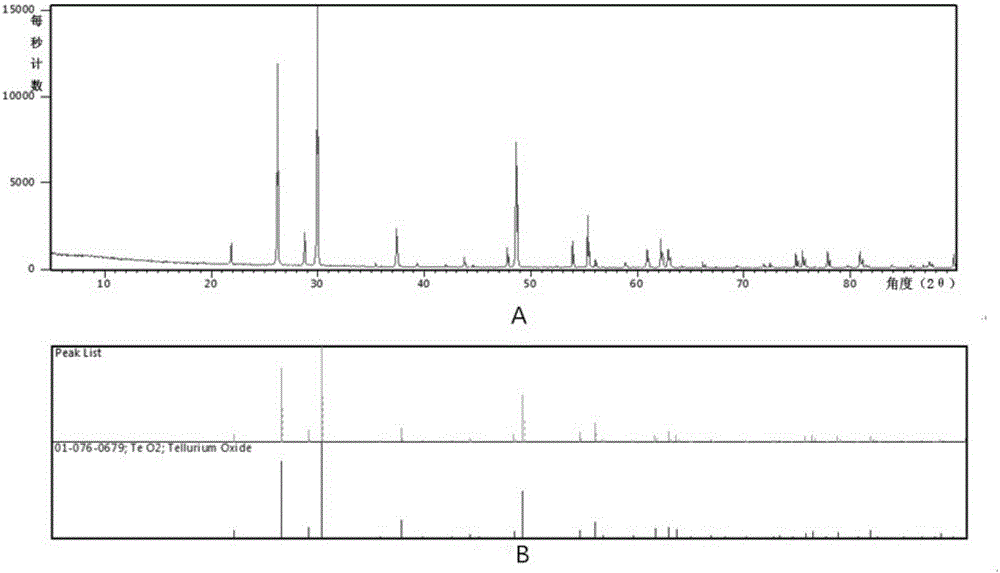

Image

Examples

Embodiment 1

[0039] Step 1: crushing the raw material tellurium ingot to a particle size of 250 μm;

[0040] Step 2: In a reaction kettle lined with polytetrafluoroethylene, add 150kg of 68wt% analytically pure nitric acid and 600kg of 36wt% analytically pure hydrochloric acid, stir evenly, and drop 150kg of the above-mentioned ground tellurium powder at 0.5kg / min at normal temperature, After the feeding is completed, continue to stir and react for 0.5h, and stop stirring after the reaction is complete and the leaching solution is light yellow;

[0041] Step 3: Pump the leachate into the plate frame with a corrosion-resistant centrifugal pump to filter;

[0042] Step 4: adding 0.2% dispersant of tellurium dioxide mass fraction to the filtrate;

[0043] Step 5: Pour the filtrate into a neutralization reactor, add deionized water to dilute it by one time, and adjust the pH to 7 with 20% ammonium hydroxide solution. Solid-liquid separation after the neutralization reaction is complete;

[...

Embodiment 2

[0049] Step 1: crush 100 kg of raw material tellurium ingots to a particle size of 200 μm, and set aside;

[0050] Step 2: In a reactor lined with polytetrafluoroethylene, add 100 wtkg of 68wt% analytically pure nitric acid and 400kg of 36% analytically pure hydrochloric acid, stir evenly, and drop 100kg of the above-mentioned ground tellurium powder at 0.3kg / min at normal temperature, After the feeding is completed, continue to stir and react for 2 hours, and stop stirring after the reaction is complete and the leaching solution is light yellow;

[0051] Step 3: Pump the leachate into the plate frame with a corrosion-resistant centrifugal pump to filter;

[0052] Step 4: adding 0.3% dispersant of tellurium dioxide mass fraction to the filtrate;

[0053] Step 5: Put the filtrate into a neutralization reaction kettle, add deionized water to dilute it by one time, and adjust the pH to 8 with 20% ammonium hydroxide. Solid-liquid separation after the neutralization reaction is c...

Embodiment 3

[0059] Step 1: crush 180 kg of raw material tellurium ingots to a particle size of 240 μm, and set aside;

[0060] Step 2: In a reaction kettle lined with polytetrafluoroethylene, add 180kg of 68wt% analytically pure nitric acid and 720kg of 36wt% analytically pure hydrochloric acid, stir evenly, and drop 180kg of the above-mentioned ground tellurium powder at 0.4kg / min at normal temperature, After the feeding is completed, continue to stir and react for 0.8h, and stop stirring after the reaction is complete and the leaching solution is light yellow;

[0061] Step 3: Pump the leachate into the plate frame with a corrosion-resistant centrifugal pump to filter;

[0062]Step 4: adding 0.5% dispersant of tellurium dioxide mass fraction to the filtrate;

[0063] Step 5: Put the filtrate into a neutralization reaction kettle, add deionized water to dilute it by one time, and adjust the pH to 9 with 20% ammonium hydroxide. Solid-liquid separation after the neutralization reaction i...

PUM

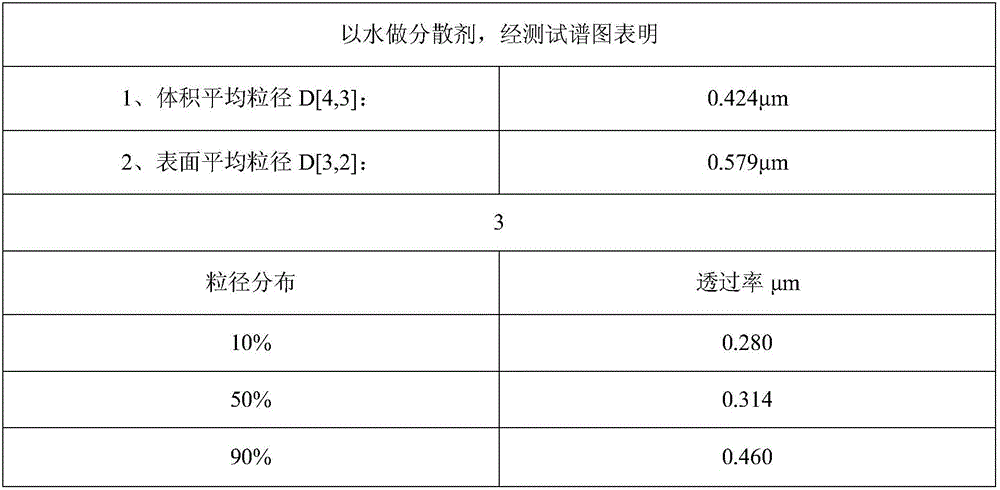

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com