Tellurium copper slag treatment method

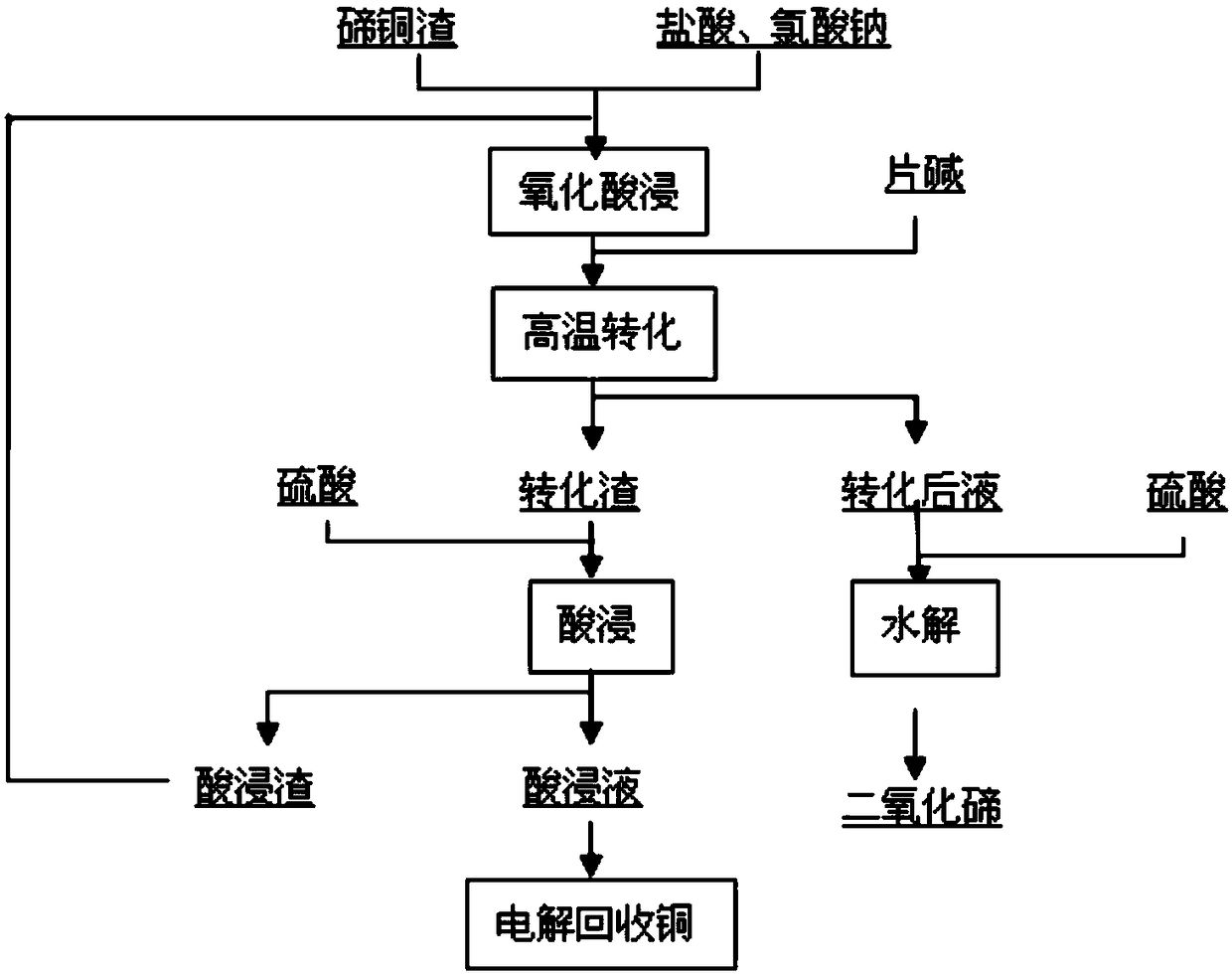

A treatment method, the technology of tellurium-copper, applied in the field of tellurium-containing materials, can solve the problems of reduced tellurium recovery rate, difficulty in separating copper and tellurium, and poor separation effect of sulfate roasting process, so as to save equipment investment and achieve separation effect Thorough, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Oxidative acid leaching:

[0051] Take 1 kg of tellurium copper slag (Cu 45%, Te 28%, Se 3%, Bi 0.1%, Sb 0.5%), according to the liquid-solid ratio of 5:1, add hydrochloric acid with a concentration of 5mol / L, start stirring, and heat up to 70 ℃, add 450g of sodium chlorate which is 1.1 times the theoretical amount, leaching for 2 hours; filter to obtain 5L oxidative acid leaching solution, acid leaching solution composition: Te 53.7g / L, Cu 88g / L, Se 3g / L, Bi 0.2 g / L.

[0052] 2. Alkaline conversion:

[0053] Take 5L of oxidizing acid immersion solution, add caustic soda to adjust pH=14, heat the solution to boil for 1 hour, filter to obtain 4L of alkali conversion solution, composition of alkali conversion solution: Te 63g / L, Cu 0.01g / L, Se 3.7 g / L, Bi 0.01g / L. At the same time, 650 g of alkali conversion slag was obtained, the composition: Cu 68%, Te 2.5%, Se 0.2%, Bi 0.15%.

[0054] 3. Acidic hydrolysis of alkaline conversion solution:

[0055] Add 4L of alka...

Embodiment 2

[0060] 1. Oxidative acid leaching:

[0061] Take 2kg of tellurium copper slag (Cu 50%, Te 26%, Se 2%, Bi 0.1%, Sb 0.4%), according to the liquid-solid ratio of 5:1, add hydrochloric acid with a concentration of 5mol / L, start stirring, and heat up to 80 ℃, add 880g of sodium chlorate which is 1.1 times of the theoretical amount, leaching for 2h; filter to obtain 10L oxidative acid leaching solution, acid leaching solution composition: Te 50g / L, Cu 98g / L, Se 2g / L, Bi 0.1g / L.

[0062] 2. Alkaline conversion:

[0063] Add 10L of oxidizing acid immersion solution, add caustic soda to adjust pH = 14, heat the solution to boil, boil for 1h, filter, the alkali conversion solution is 8.9L, the composition of the alkali conversion solution: Te 51g / L, Cu 0.01g / L, Se 2g / L, Bi 0.01g / L. At the same time, 1452 g of alkali conversion slag was obtained, the composition: Cu 67.5%, Te 3%, Se 0.17%, Bi 0.12%.

[0064] 3. Acidic hydrolysis of alkaline conversion solution:

[0065] Add 8.9L o...

Embodiment 3

[0070] 1. Oxidative acid leaching:

[0071] Take 1 kg of tellurium copper slag (Cu 45%, Te 28%, Se 3%, Bi 0.1%, Sb 0.5%), according to the liquid-solid ratio of 5:1, add sulfuric acid with a concentration of 3mol / L, start stirring, and heat up to 70 ℃, then add 295g of sodium chloride, add 450g of sodium chlorate as 1.1 times the theoretical amount, and leaching for 2 hours; filter to obtain 5L of oxidative pickling solution, the composition of the pickling solution: Te 53g / L, Cu 85g / L, Se2g / L, Bi 0.1g / L.

[0072] 2. Alkaline conversion:

[0073] Take 5L of oxidizing acid immersion solution, add caustic soda to adjust pH=14, heat the solution to boil for 1 hour, filter to obtain 4L of alkali conversion solution, composition of alkali conversion solution: Te 61g / L, Cu 0.02g / L, Se 2.4 g / L, Bi 0.01g / L. At the same time, 640 g of alkali conversion slag was obtained, the composition: Cu 66%, Te 3.3%, Se 0.06%, Bi 0.07%.

[0074] 3. Acidic hydrolysis of alkaline conversion solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com