Novel gold-tellurium separation and extraction technology for tellurium-containing gold concentrates

A gold concentrate and new process technology, which is applied to the new process field of gold and tellurium separation and extraction of tellurium-containing gold concentrate, can solve the problems of lack of extraction technology, low content, inability to price gold concentrate, etc., and achieves green environmental protection, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

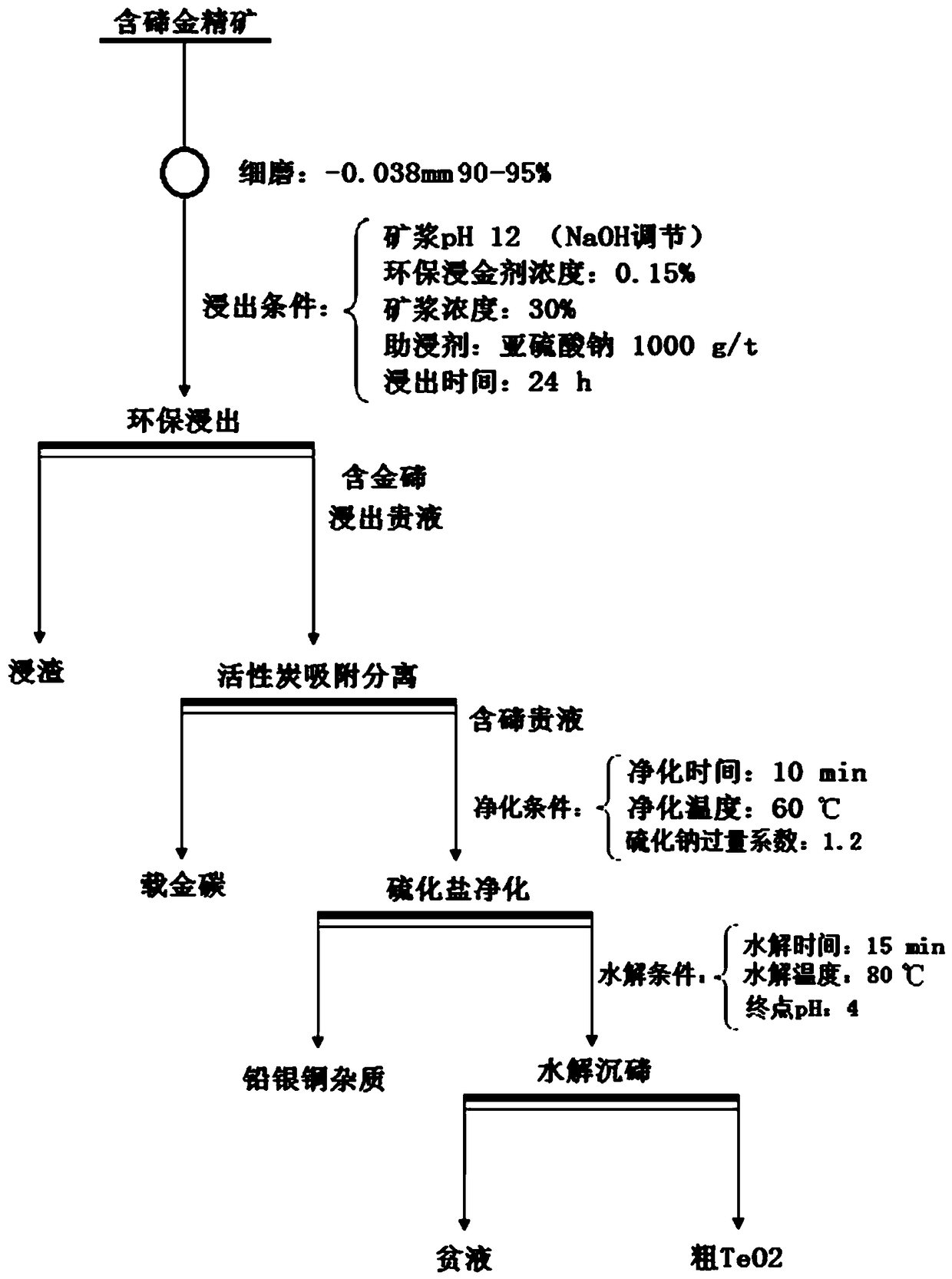

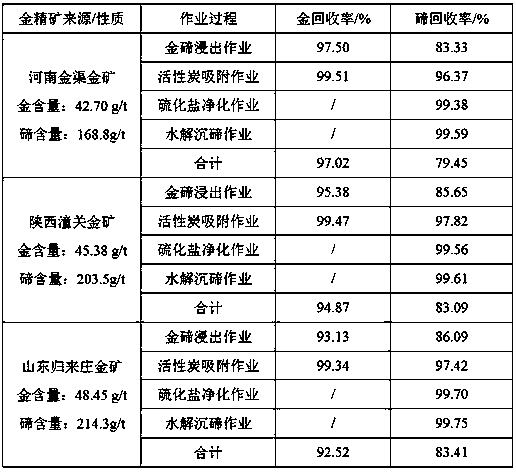

[0030] Such as figure 1 As shown, adopt the present invention to the tellurium-containing gold concentrate of Henan Jinqu Gold Mine, Shaanxi Tongguan Gold Mine, Shandong Guilaizhuang Gold Mine, and adopt this new process to carry out the test of wet separation and extraction of gold tellurium.

[0031] The three gold concentrate samples were finely ground to -0.038mm with a ball mill, accounting for 92.4%.

[0032] The mass concentration of the pulp is adjusted to 30% with water, the pH of the pulp is adjusted to 12 with NaOH, and the green gold environmental protection gold extraction agent is added as a gold dissolving agent, the concentration of the agent is kept at 0.15%, and the leaching is performed for 24 hours.

[0033] After mining activated carbon to absorb gold in the precious liquid, add sodium sulfide to remove impurities. The excess coefficient of sodium sulfide is 1.2, the temperature for removing impurities is 60 degrees Celsius, and the purification time is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com