Patents

Literature

32results about How to "Effective separation and extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

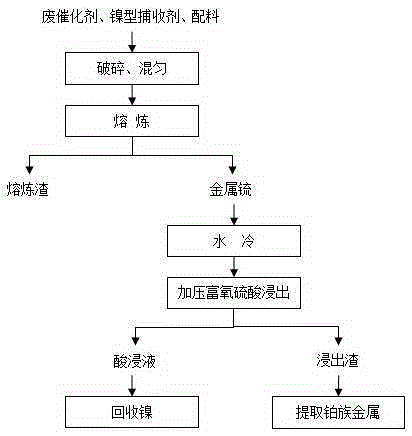

Method for recycling platinum group metal from waste catalysts

The invention discloses a method for recycling platinum group metal from waste catalysts. The method comprises the following steps that (1) the waste catalysts containing the platinum group metal, nickel type collecting agents, calcium oxide and silicon dioxide are crushed and mixed uniformly according to a proportion; (2) the proportioned mixture is smelted at the high temperature, and the constant temperature is kept for a period of time, so that molten sulfonium with nickel as main components is deposited below a slag layer of metallic oxide; (3) water cooling is conducted on the sulfonium at the high temperature, so that metal particles are obtained; (4) the crushed metal particles are leached through sulfuric acid at the high pressure, and valuable metal such as nickel is recycled from leaching liquid; and (5) the platinum group metal is further extracted from leaching slag. Compared with the prior art, the method is simple in development process, good in enrichment effect and capable of being effectively used for separation and extraction of valuable metal in the waste catalysts.

Owner:JINCHUAN GROUP LIMITED

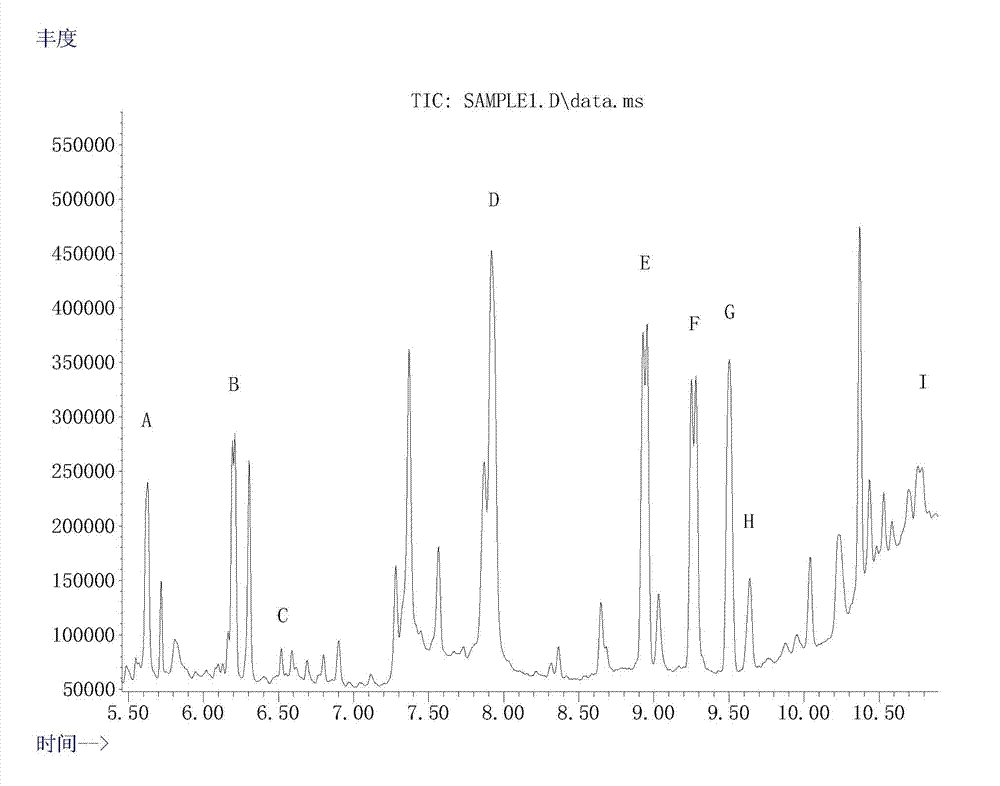

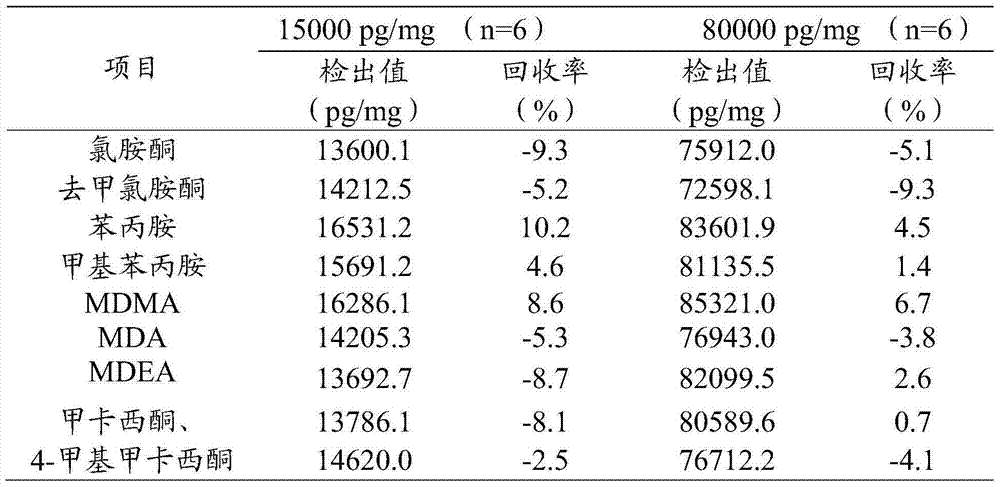

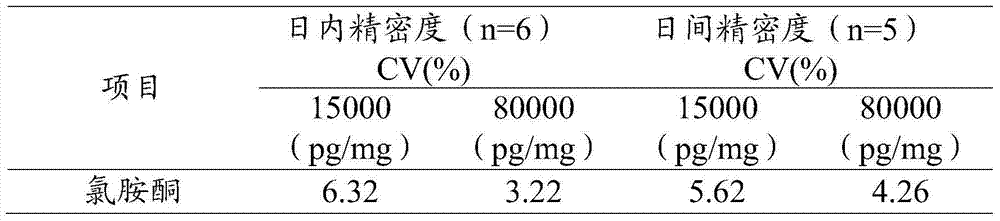

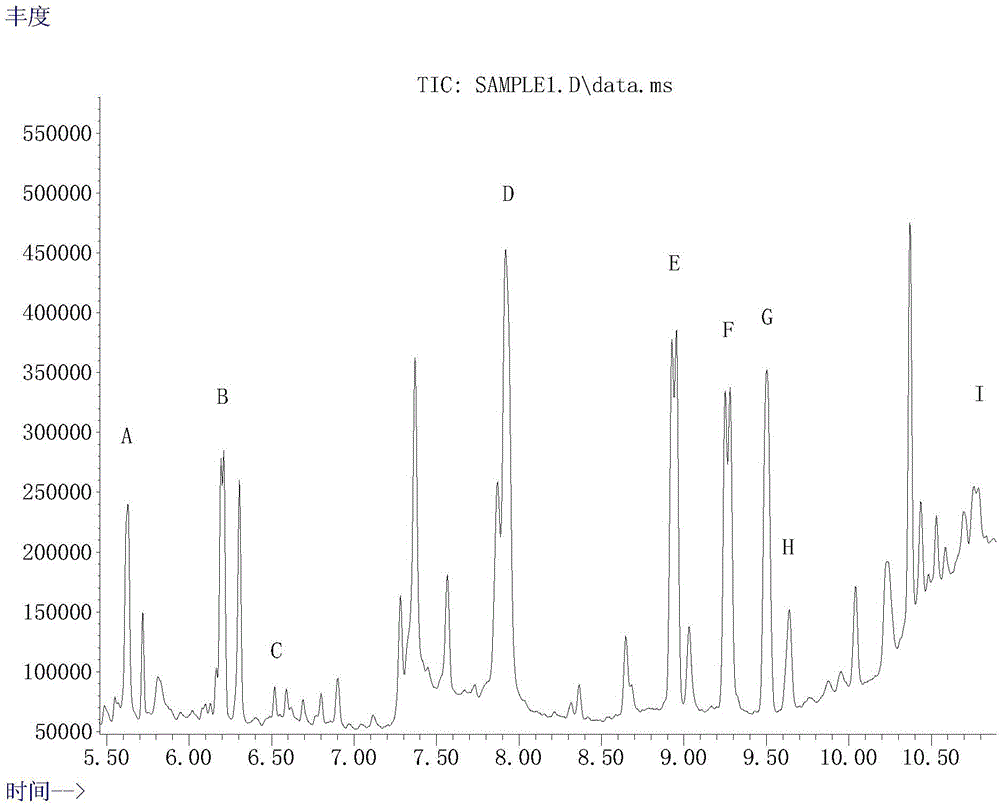

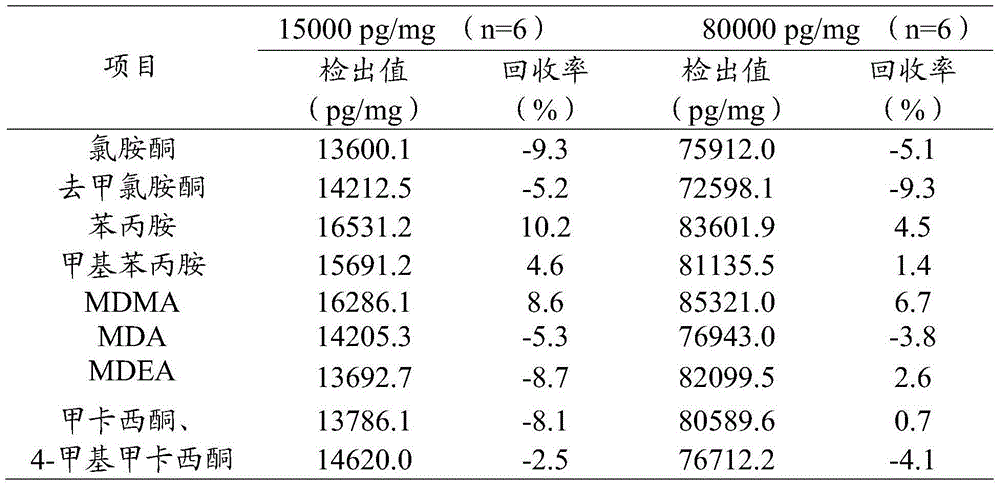

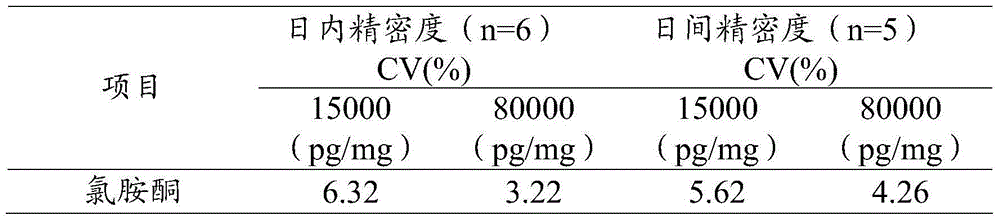

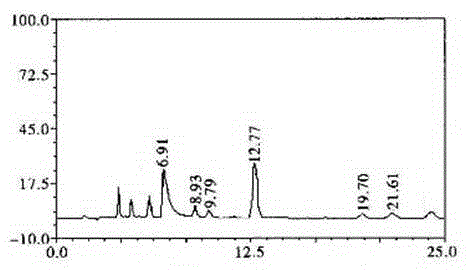

Extraction and detection method for ketamine, norketamine and amphetamin-type substances in hairs

ActiveCN103575831AEfficient removalEffective separation and extractionComponent separationFluid phaseGas liquid chromatographic

The invention provides an extraction method for ketamine, norketamine and amphetamin-type substances in hairs. The extraction method comprises the steps of extraction and purification of the hairs. The extraction method also comprises a step of derivatization. The invention also provides a method for detecting the ketamine, the norketamine and the amphetamin-type substances in the hairs, and adopts a gas chromatographic mass spectrometer or a liquid-chromatographic mass spectrometer. Compared with the traditional method for detecting poison residues of the hairs, the method provided by the invention is mild, has the advantages that drugs in the hairs are effectively extracted, multiple impurity interfering substances in hair detection materials are effectively removed and the sensitivity and the accuracy are high, and the extraction method can be used by law enforcement departments, detection departments and drug inspection institutions in the government.

Owner:广州正孚检测技术有限公司

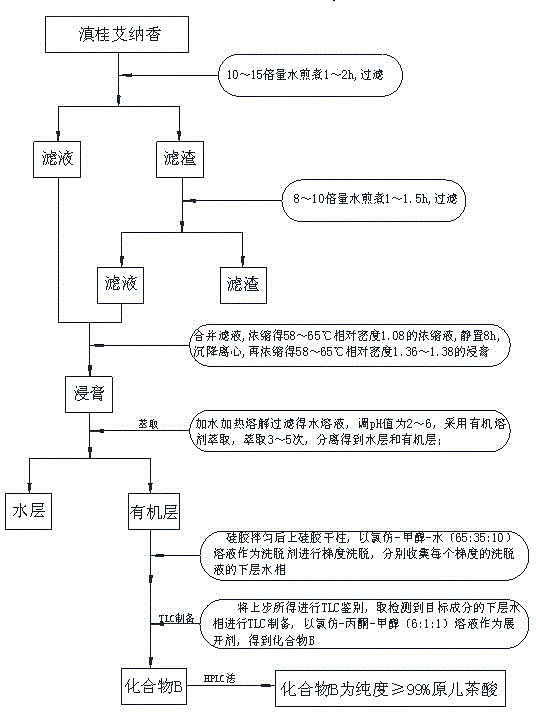

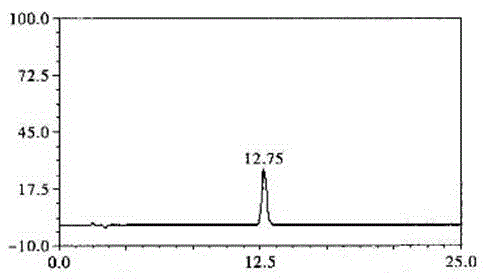

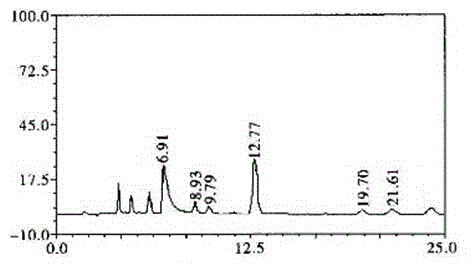

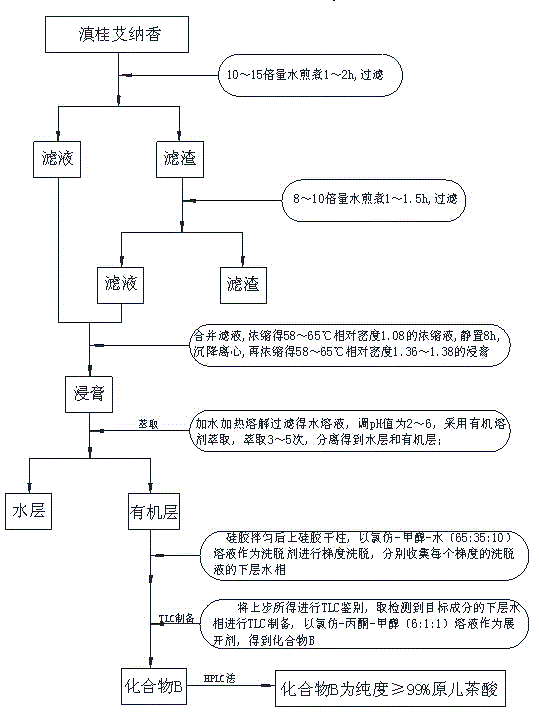

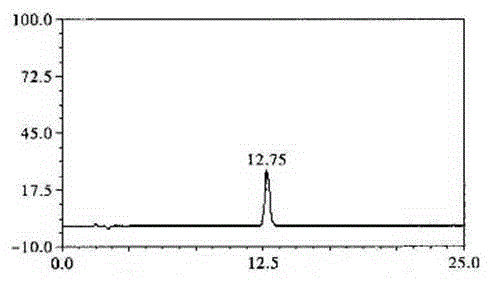

Technological method for extraction of protocatechuic acid from Blumea riparia (Bl.) DC

ActiveCN104098465AHigh purityEfficient separationCarboxylic compound separation/purificationChlorogenic acidElution

Belonging to the technical field of traditional Chinese medicine extraction, the invention discloses a technological method for extraction of protocatechuic acid from Blumea riparia (Bl.) DC. The method for preparation of a protocatechuic acid monomer consists of: water extraction, concentration, extraction, elution, and TLC preparation and purification. A compound B is determined as protocatechuic acid with a concentration of equal to or more than 99% by HPLC analysis, and is the protocatechuic acid monomer. The technological method for extraction of chlorogenic acid from Blumea riparia (Bl.) DC solves the problems of low preparation purity, small preparation quantity, complex preparation process, and difficult realization of industrialization production. By means of water extraction, concentration, extraction, elution and other processes, high extraction purity and a simple preparation process can be realized. Thus, the method is suitable for popularization, and meets the need of people for protocatechuic acid.

Owner:广西万寿堂药业有限公司

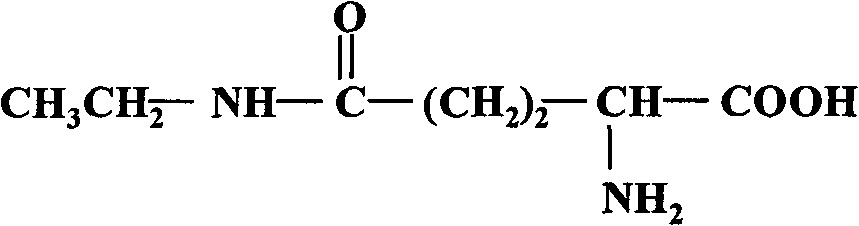

Method for separating and extracting natural theanine

InactiveCN101805269AImprove mechanical propertiesPromote regenerationCarboxylic acid amide separation/purificationTheanineVacuum evaporation

The invention belongs to the technical field of deep processing of tea, particularly relates to a method for separating and extracting natural theanine. At the temperature of 5-75 DEG C, aqueous solution containing theanine is enabled to flow through an adsorbing column filled with inorganic zeolite molecular sieve adsorbent; the theanine is adsorbed; ammonia spirit is used to elute the theanine adsorbed by the adsorbing column; alcohol is added after vacuum evaporation and concentration are carried out on the eluent; the theanine is separated out when the temperature is cooled to be about 0 DEG C; pumping filter is carried out; and recrystallization is carried out for 1-3 times to obtain a product the theanine content of which is more than 90%. The adsorbent can be repeatedly regenerated and reused, and the operational process is safe, simple and convenient and has low energy consumption. The invention is suitable for separating and extracting the theanine from a tea leaching solution, is especially suitable for processing low-grade tea, rough and old tea, tea tree roots and the like, or can be used for utilizing leftovers, waste liquor containing the theanine and other plants containing the theanine in the deep processing process of the tea.

Owner:晋江市恒源科技开发有限公司 +1

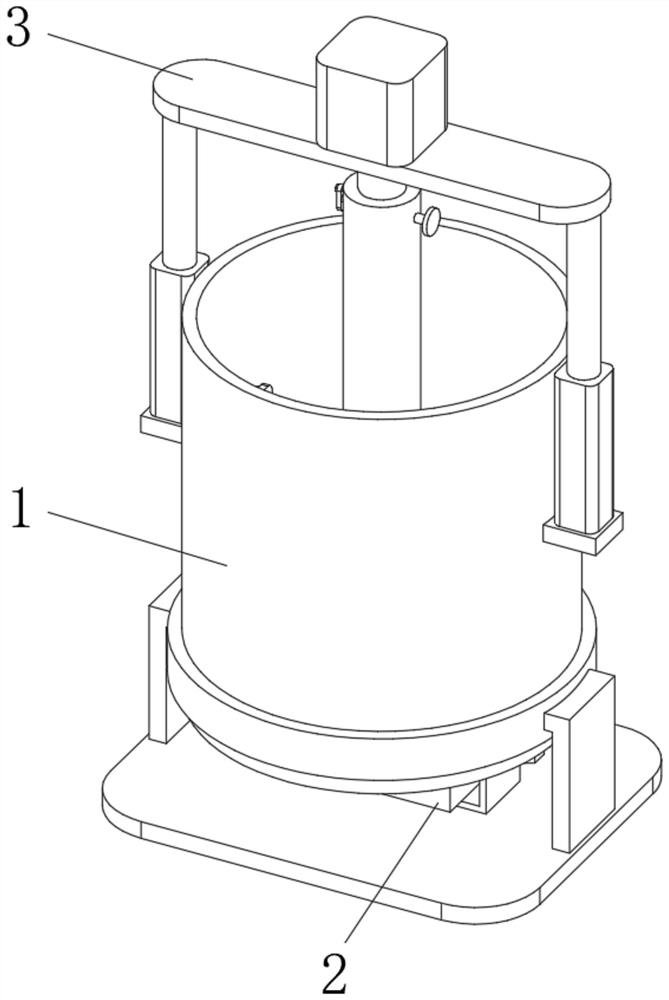

Refining and filtering device for crude linseed oil

ActiveCN111876247AIncrease contact areaAvoid cloggingFatty-oils/fats refiningFatty substance recoveryProcess engineeringLinseed oil

The invention provides a refining and filtering device which comprises a fixed base, wherein supporting frames are fixedly connected to the two sides of the top of the fixed base, a supporting table plate is fixedly connected to the tops of the supporting frames, a groove hole is formed in the surface of the supporting table plate, and an oil collecting funnel is arranged in the groove hole; vertical plates are fixedly connected to the two sides of the top of the supporting table plate, an arc-shaped sliding rail is fixedly connected between one side of each vertical plate and the supporting table plate, a primary filtering assembly is arranged between the two vertical plates, a containing boss is integrally arranged on the inner side of the supporting frame, and a fine filtering assemblyis arranged on the inner side of the containing boss. Based on cooperation of the primary filtering assembly and the fine filtering assembly, the visible impurities and dissolved impurities in crude oil are intercepted through primary filtering, boiling, filtering and fine filtering, wherein the contact area between the filtering net and oil is increased, the impurities shake and deviate towards one side to be concentrated, filtering holes are prevented from being blocked, and thereby the filtering efficiency and the filtering precision are improved.

Owner:渭源县渭宝源商贸有限公司

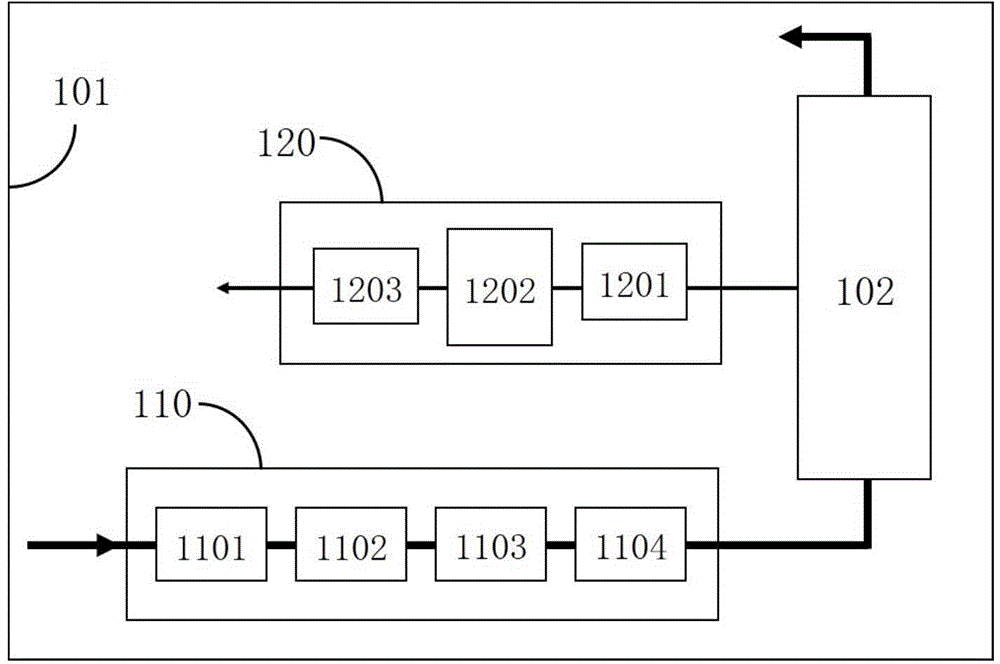

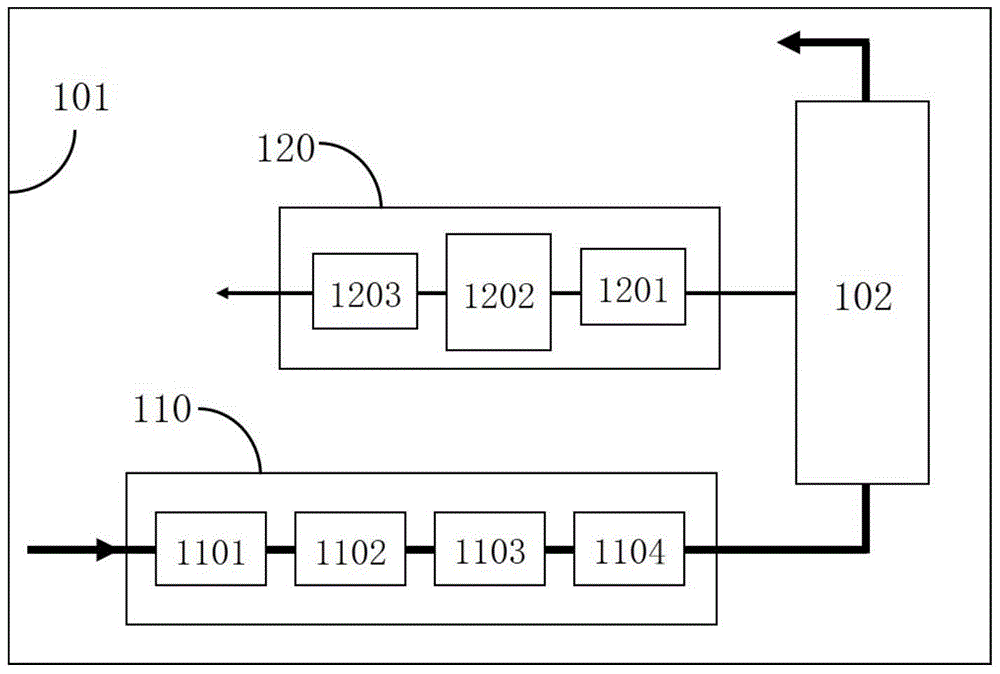

System and method for separating and extracting dissolved gas from environmental water

ActiveCN104609583AImprove portabilityAchieve dimmingPreparing sample for investigationTesting waterEnvironmental engineeringEnvironmental water

The invention discloses a system and method for separating and extracting dissolved gas from environmental water. The system is characterized by comprising a water-quality treatment device, a membrane degassing device, a vacuum collection device and a flow control device. The treatment method is characterized by comprising the following steps of firstly removing impurity particles in the environmental water by virtue of the water-quality treatment device, degassing the dissolved gas in the environmental water by virtue of the membrane degassing device and further discharging degassed environmental water; and finally further pumping and collecting the dissolved gas generated in the membrane degassing device into an gas cylinder by virtue of the vacuum collection device. The system disclosed by the invention has the characteristics of low cost, simple operation, high degassing efficiency, convenient carrying and maintenance, low weight, small size and the like, can be carried by single people and has almost no any application limitation on the extreme field environment so that the system is very suitable for extracting dissolved gas from the environmental water.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

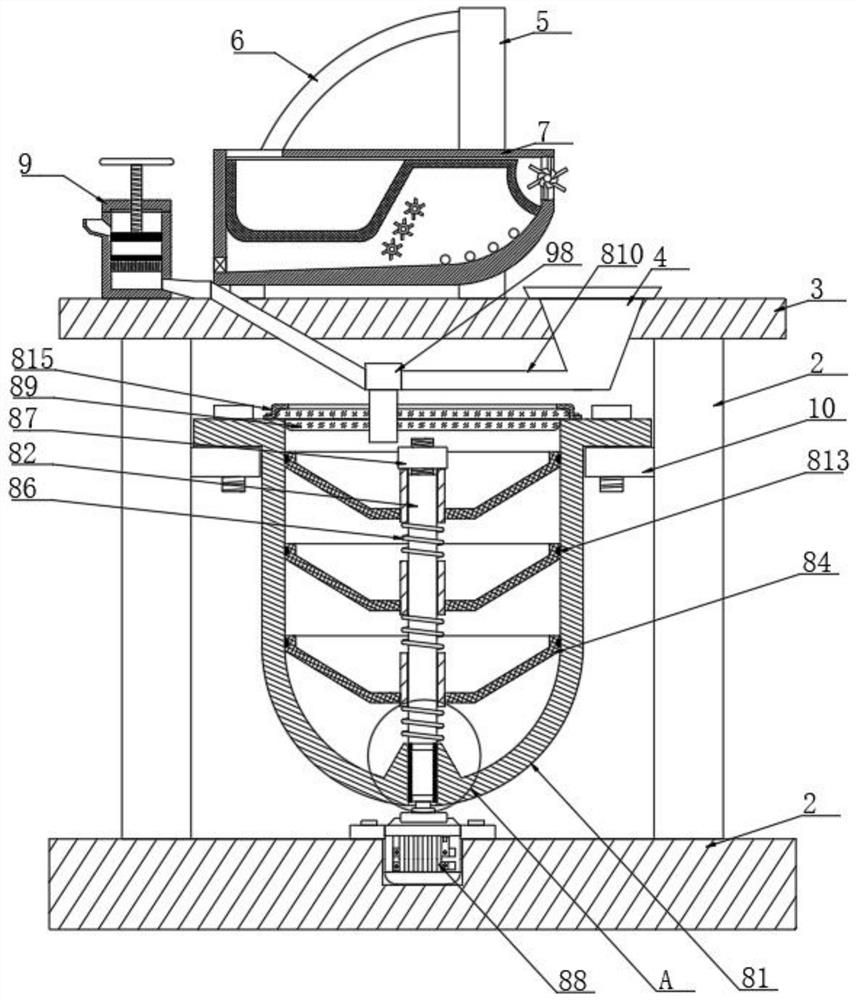

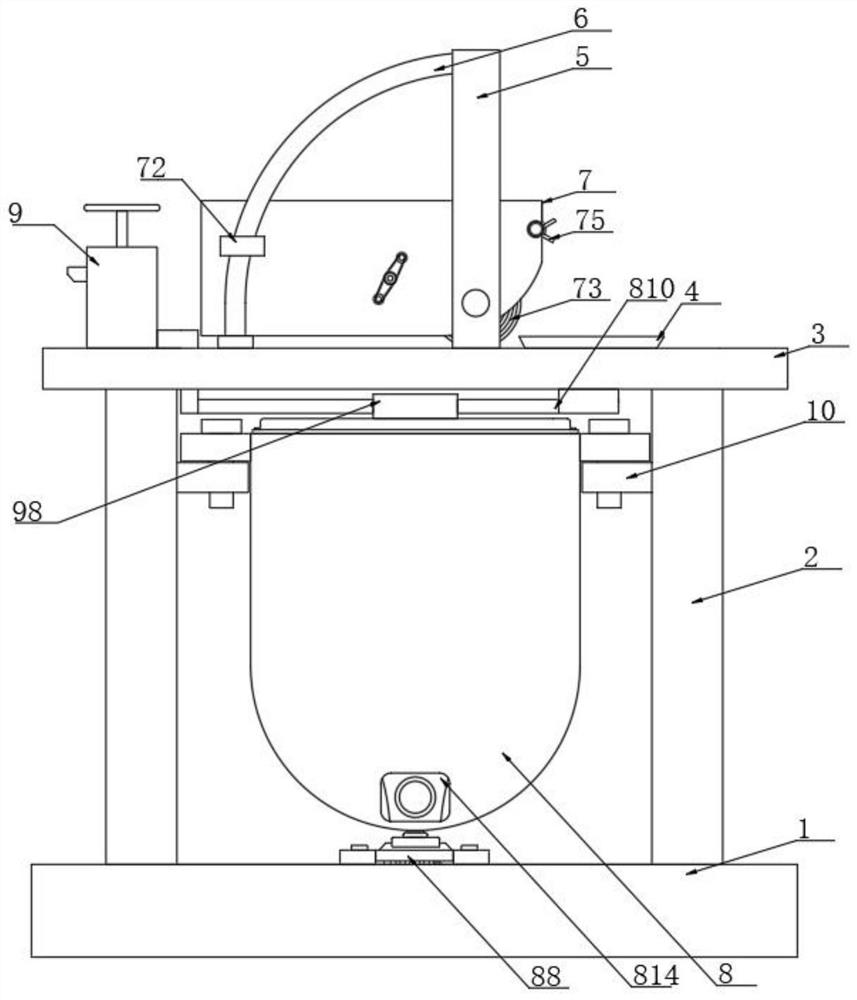

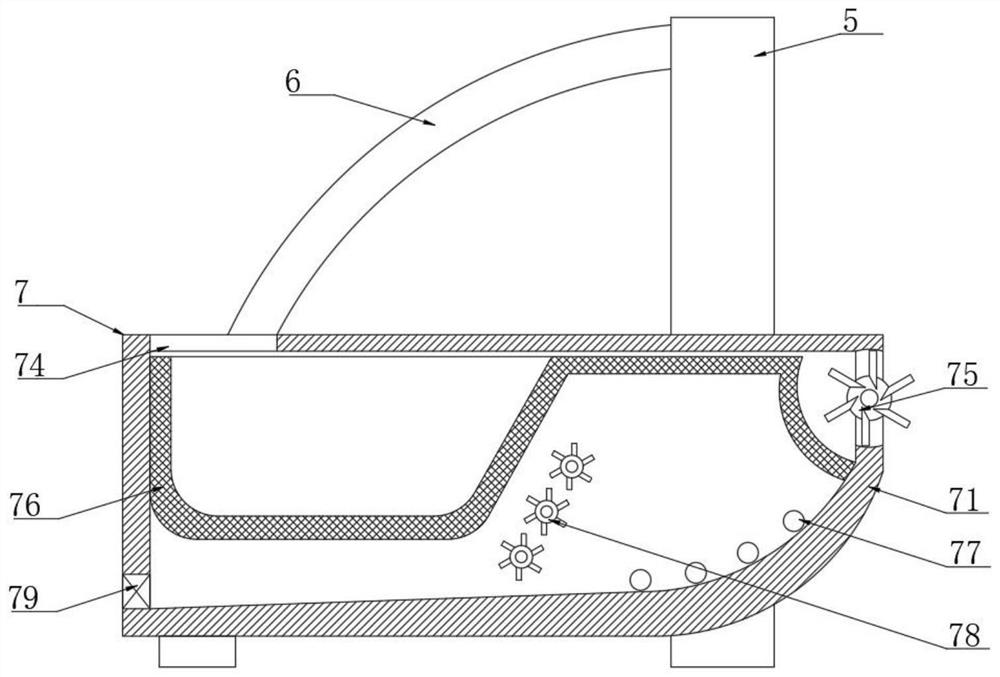

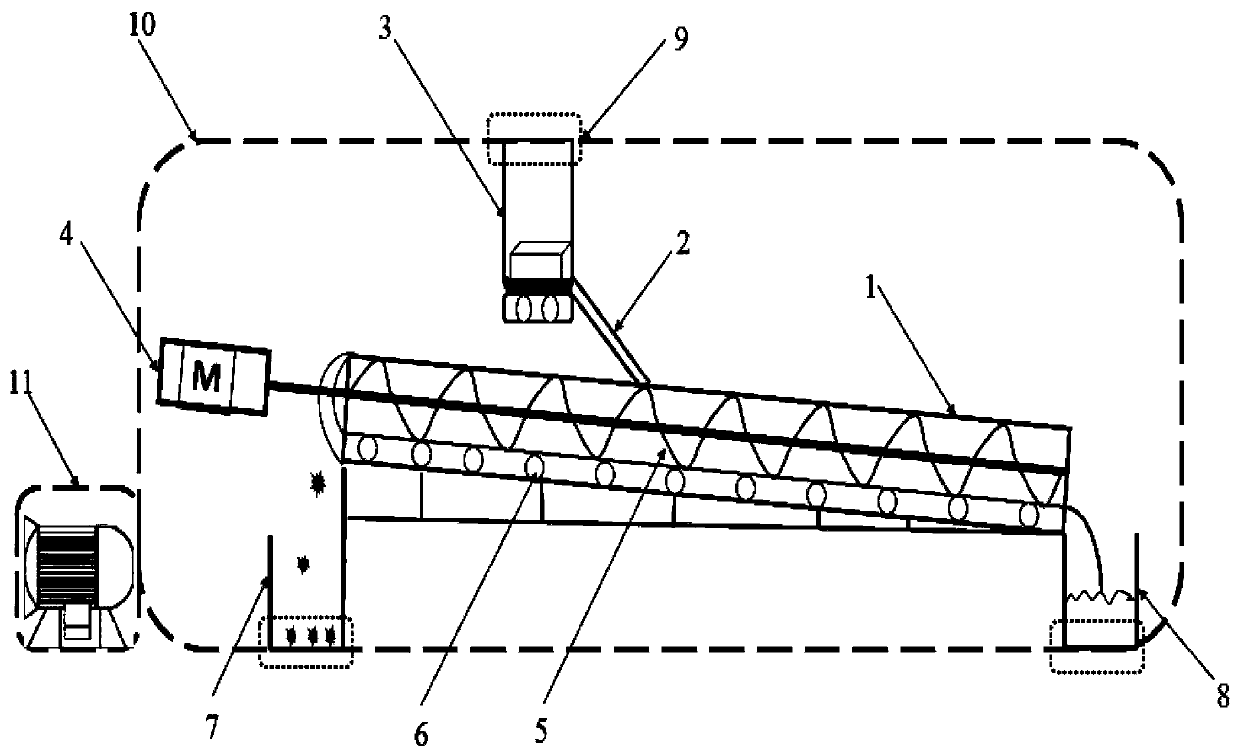

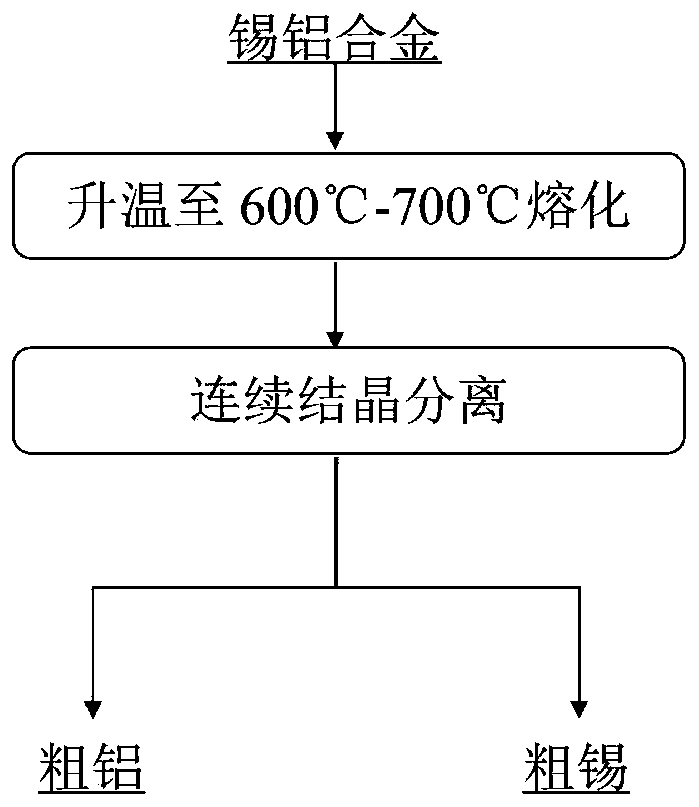

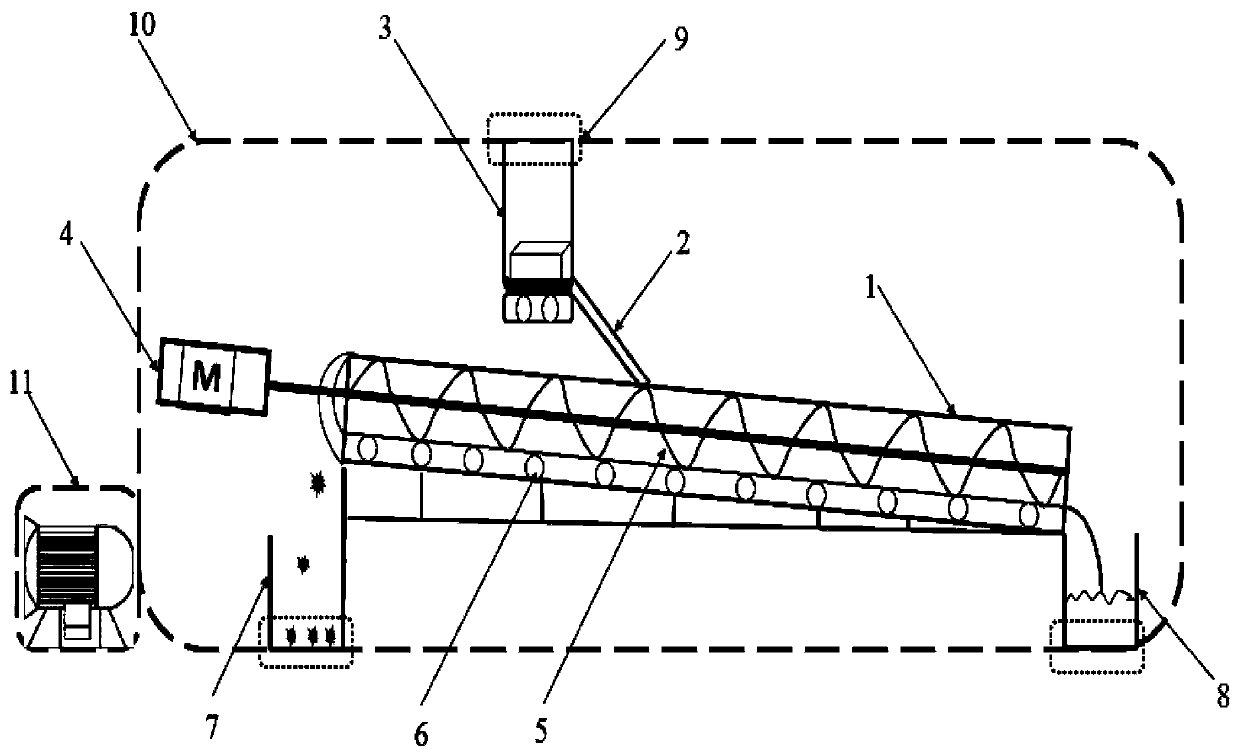

Device and method for recovery, separation and purification of aluminum-tin alloy through vacuum continuous crystallization

PendingCN111172394ASimple processEasy to operateProcess efficiency improvementAluminiumContinuous crystallization

The invention discloses a device and method for recovery, separation and purification of an aluminum-tin alloy through vacuum continuous crystallization. The device comprises a shell, a vacuum pump, aU-shaped crystallization tank, a melting pot, a melt pot and a crystal pot. The shell is of a vacuum sealed structure, the U-shaped crystallization tank, the melting pot, the melt pot and the crystalpot are all arranged in an inner cavity of the shell, the U-shaped crystallization tank is arranged in an inclined mode, a tank head is arranged at the higher end of the U-shaped crystallization tank, a tank tail is arranged at the lower end of the U-shaped crystallization tank, the crystal pot is connected with the tank head, the melt pot is connected with the tank tail, a plurality of heating elements are arranged at the bottom of the U-shaped crystallization tank, the temperature of the tank head is higher than that of the tank tail, and a screwing device is arranged in the U-shaped crystallization tank and driven by a motor. According to the device and method for recovery, separation and purification of the aluminum-tin alloy through vacuum continuous crystallization, effective separation and purification of aluminum and tin in aluminum tin is achieved through continuous crystallization under vacuum conditions, and crude aluminum and crude tin are finally obtained, the process issimple, the operation is convenient, the raw material has high universality, the cost is low, the device is simple, the process is safe and controllable, and the aluminum-tin alloy with a wide range of quality change can be treated.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting lithium carbonate from lithium-rich clay by acid-base combination method

ActiveCN113955775AEffective separation and extractionReduce remaining amountLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention relates to a method for extracting lithium carbonate from lithium-rich clay by an acid-base combination method, the method comprises the following steps: adding the lithium-rich clay into a sulfuric acid solution with a certain concentration for leaching, and then filtering and separating to obtain an acid leaching solution and acid leaching residues; adding a sodium hydroxide solution into the acid leaching residues for alkaline leaching, then performing filtering separation, and obtaining alkaline leaching liquid and alkaline leaching residues; and introducing carbon dioxide gas into the alkaline leaching solution, and filtering when the pH value reaches 8.5-10.5 to obtain a lithium carbonate solid and a carbon component mother solution. The method has the advantages of being simple in technological process, free of special requirements for equipment, low in energy consumption, good in controllability of technological parameters, small in residual amount of residues, low in production cost and the like, and a new way is opened up for development and utilization of the lithium-rich clay.

Owner:潘爱芳

Extraction and detection method for ketamine, norketamine and amphetamin-type substances in hairs

ActiveCN103575831BEfficient removalEffective separation and extractionComponent separationDerivatizationNorketamine

The invention provides an extraction method for ketamine, norketamine and amphetamin-type substances in hairs. The extraction method comprises the steps of extraction and purification of the hairs. The extraction method also comprises a step of derivatization. The invention also provides a method for detecting the ketamine, the norketamine and the amphetamin-type substances in the hairs, and adopts a gas chromatographic mass spectrometer or a liquid-chromatographic mass spectrometer. Compared with the traditional method for detecting poison residues of the hairs, the method provided by the invention is mild, has the advantages that drugs in the hairs are effectively extracted, multiple impurity interfering substances in hair detection materials are effectively removed and the sensitivity and the accuracy are high, and the extraction method can be used by law enforcement departments, detection departments and drug inspection institutions in the government.

Owner:广州正孚检测技术有限公司

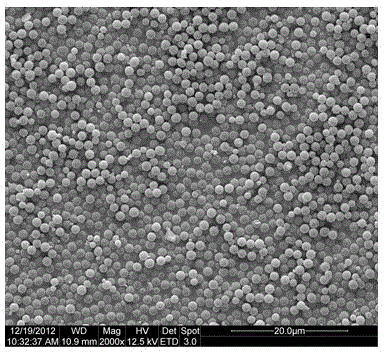

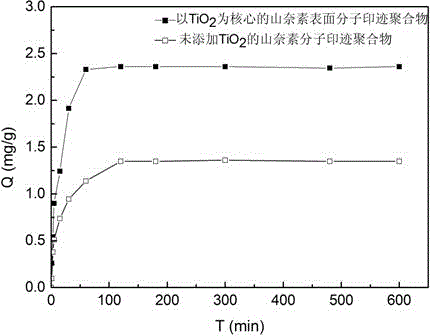

Preparation method and application of kaempferol imprinted microsphere based on nanometer titanium dioxide

InactiveCN104804152AParticle shape rulesUniform sizeOther chemical processesAlkali metal oxides/hydroxidesMolecularly imprinted polymerTitanium dioxide

The invention provides a preparation method of a kaempferol surface molecularly imprinted polymer microsphere with TiO2 as a core by adopting a seed precipitation polymerization technology. The method solves the problems of severe embedding phenomenon and low separating treatment efficiency of polymer microspheres prepared through a precipitation polymerization technology and the problem of easy gelatinization of an initiator in a polymerization solution in the preparation process of imprinted microspheres prepared through a surface imprinting technology needing a surface grafting technology. An imprinted polymer microsphere prepared through adopting the method has the advantages of regular particle shape, uniform size, no agglomeration phenomenon and increased specific surface area, and makes binding sites of a polymer distributed on the surface of the microsphere in order to improve the adsorption performance of the kaempferol surface molecularly imprinted polymer microsphere. The above polymer prepared in the invention can realize effective separation and extraction of ginkgo flavone aglycone, and has a wide application prospect.

Owner:BEIJING FORESTRY UNIVERSITY

Method for extracting Zn, Mn, Pb and Ag from zinc electrolysis anode mud

InactiveCN107245579AEffective separation and extractionTake advantage ofProcess efficiency improvementLiquid wasteElectrolysis

The invention relates to the technical field of wet metallurgy, in particular to a method for extracting Zn, Mn, Pb and Ag from zinc electrolysis anode mud. By means of the total six steps of washing, ball milling, electrolyzing, leaching, replacement and liquid waste treatment, the process of extracting zinc, manganese, lead and silver from the zinc electrolysis anode mud is completed, the separation effect is remarkable, the cost is low, the metal recovering rate is high, the quality is good, waste residues and liquid waste are fully utilized in the whole process, and little pollution is caused.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

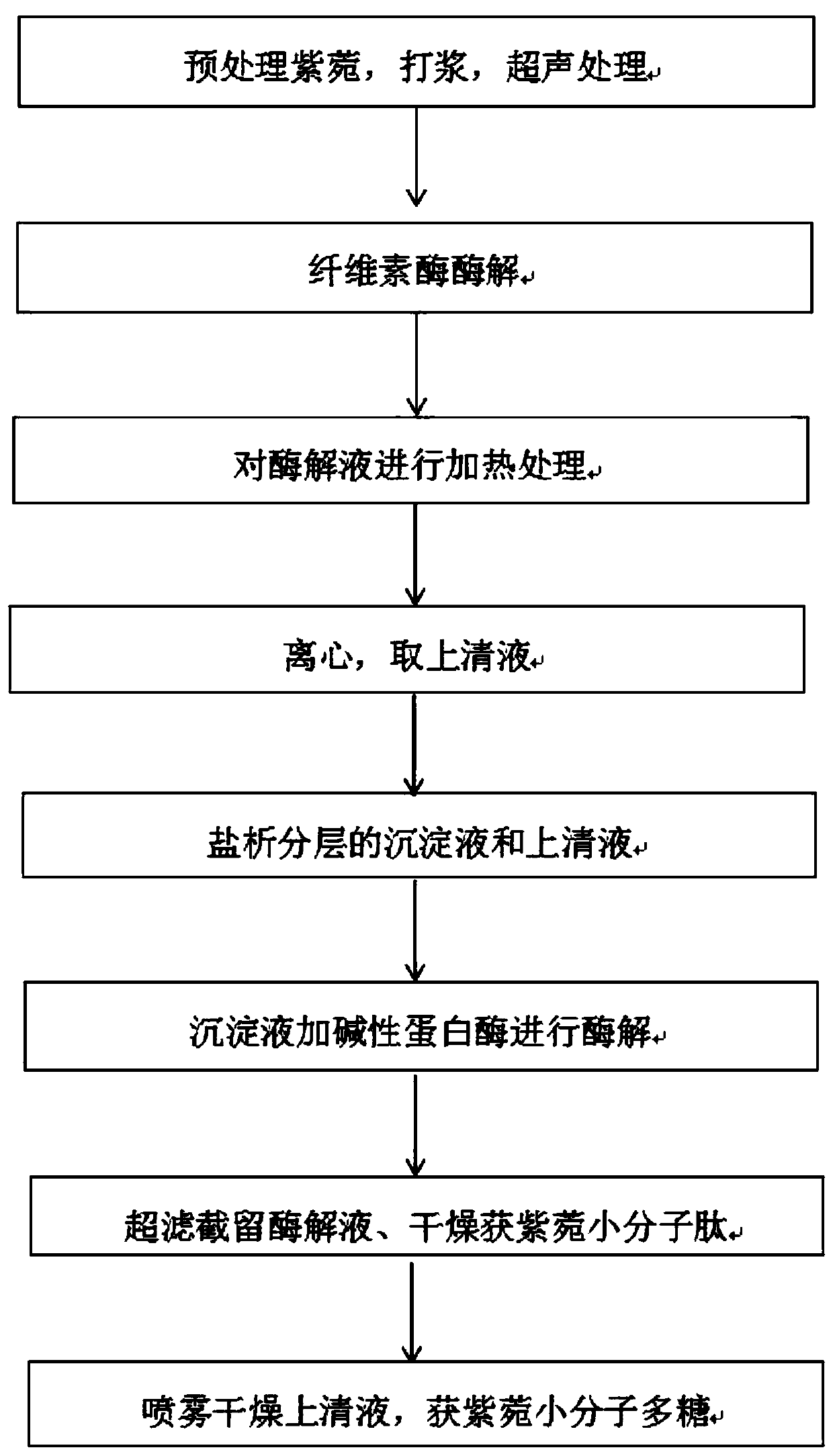

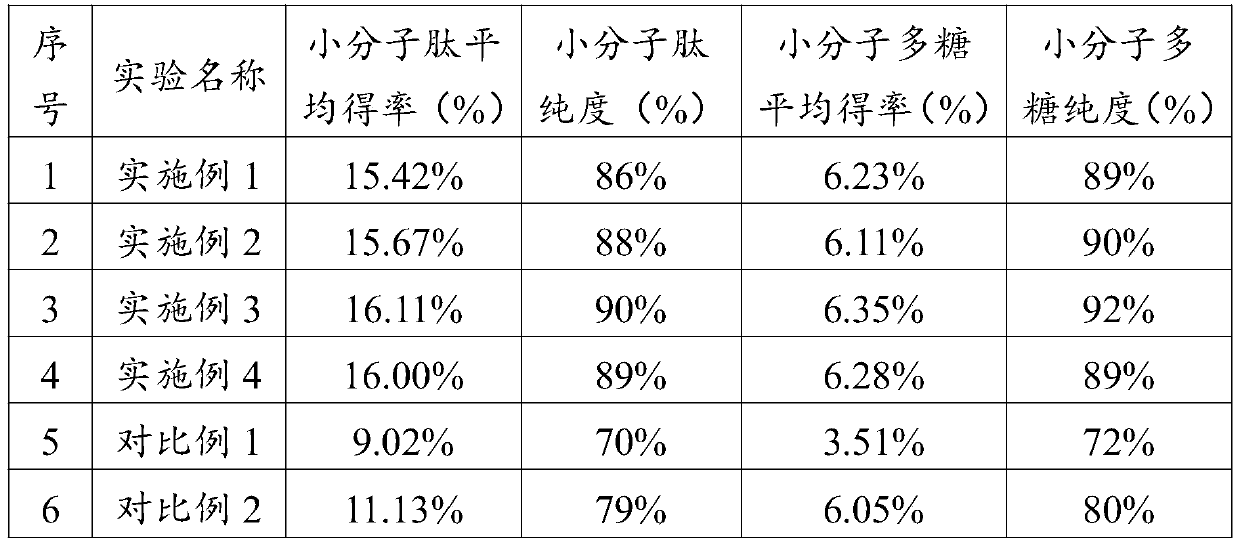

Extraction method of radix asteris polysaccharide and radix asteris polypeptide

InactiveCN110964767AImprove whole fruit utilizationEffective separation and extractionPeptide preparation methodsFermentationAlkaline proteaseHydrolysate

The invention, which belongs to the technical field of plant extraction, provides an extraction method of radix asteris polysaccharide and radix asteris polypeptide. The method comprises the followingsteps: step one, mixing and pulping radix asteris and water, and carrying out ultrasonic treatment to obtain a radix asteris slurry; step two, mixing the radix asteris slurry with cellulase, and carrying out first enzymolysis; step three, treating the first enzymatic hydrolysate at a temperature of 30-50 DEG C for 30-50 minutes, and then carrying out solid-liquid separation; step four, adjustingthe pH value of first clear liquid to be 4-7, mixing the first clear liquid with a sulfate mixture, and carrying out salting-out layering to obtain a second supernatant and lower-layer precipitation liquid; step five, mixing the lower-layer precipitation solution with alkaline protease, carrying out second enzymolysis to obtain a second enzymatic hydrolysate, and performing ultrafiltration and nanofiltration on the second enzymatic hydrolysate and drying the processed solution to obtain radix asteris polypeptide; and step six, drying the second supernatant obtained in the step four to obtain the radix asteris polysaccharide. With the method, simultaneous extraction of the radix asteris polysaccharide and the radix asteris polypeptide can be realized; and the yield is high.

Owner:河北中科同创科技发展有限公司

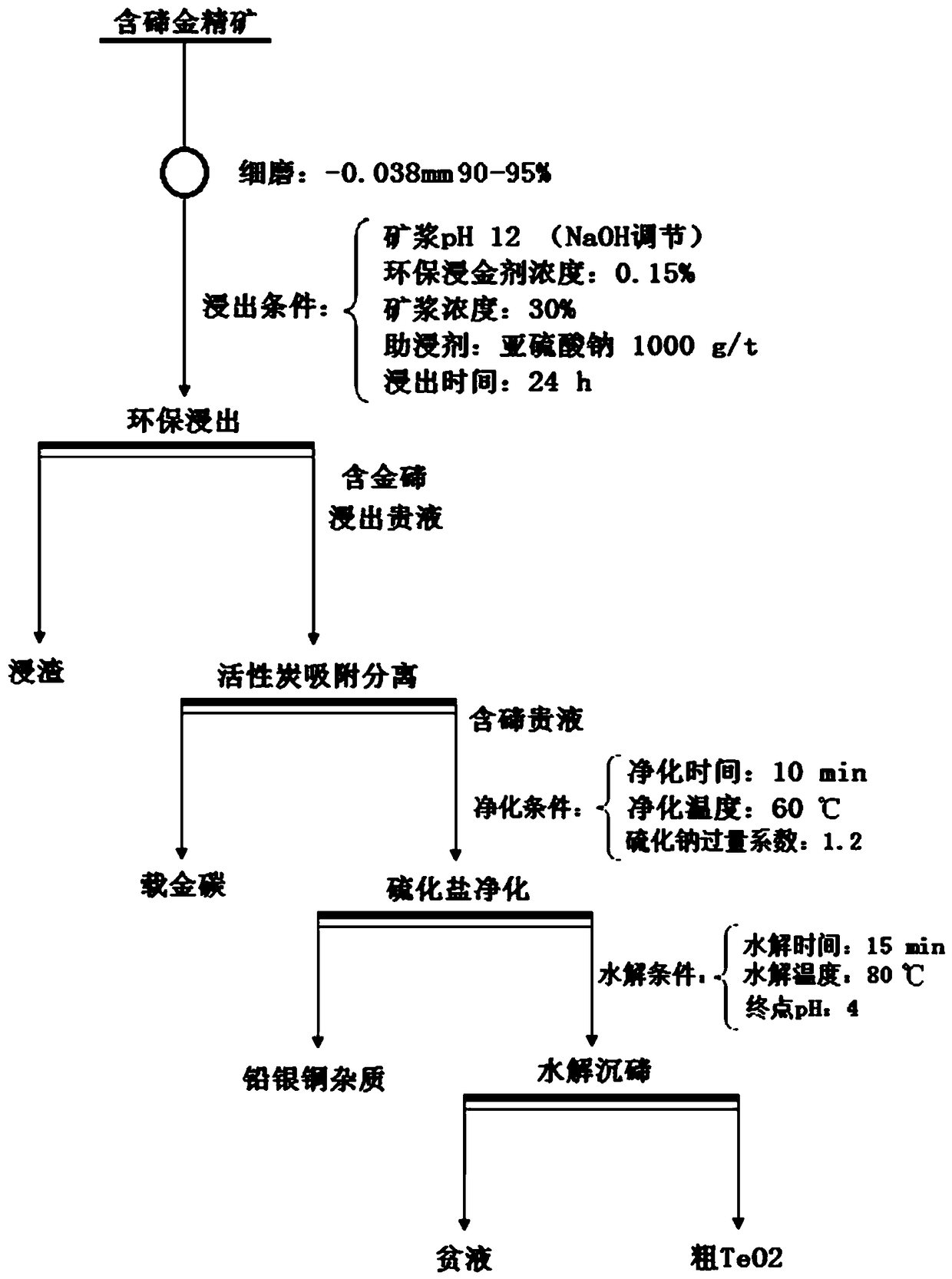

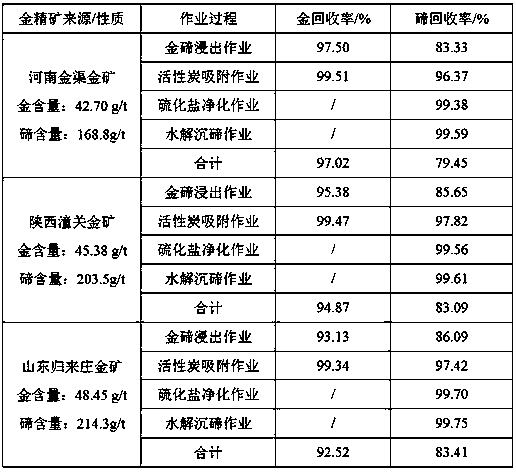

Novel gold-tellurium separation and extraction technology for tellurium-containing gold concentrates

InactiveCN108411109AEffective separation and extractionProcess environmental protectionProcess efficiency improvementSelenium/tellurium oxides/hydroxidesActivated carbonAlkalinity

The invention discloses a novel gold-tellurium separation and extraction technology for tellurium-containing gold concentrates. The novel gold-tellurium separation and extraction technology comprisesthe steps that firstly, the tellurium-containing gold concentrates are subjected to fine grinding, so that gold and tellurium are exposed from wrapping of sulfide ores; then, the concentration and alkalinity of ore pulp are adjusted in a stirring leaching tank through water and NaOH, an environment-friendly gold leaching agent is added, and gold and tellurium are leached simultaneously; by utilizing the characteristic that activated carbon adsorbs gold selectively but does not adsorb tellurium, gold is adsorbed and separated in a leaching pregnant solution, and gold-bearing carbon is formed; and after being subjected to impurity removing through sulphurizing salt, the tellurium-containing pregnant solution is subjected to neutralizing hydrolysis through sulfuric acid, so that tellurium isprecipitated from the solution, a rough TeO2 product is formed, and effective separation and extraction of gold and tellium are achieved. The technological method is simple in process, environmentallyfriendly and free of pollution, and the recovery rates of gold and tellurium are high.

Owner:ZHENGZHOU UNIV +1

A system and method for separating and extracting dissolved gas from environmental water

ActiveCN104609583BEffective separation and extractionReduce pollutionPreparing sample for investigationMultistage water/sewage treatmentGas cylinderWater quality

The invention discloses a system and method for separating and extracting dissolved gas from environmental water. The system is characterized by comprising a water-quality treatment device, a membrane degassing device, a vacuum collection device and a flow control device. The treatment method is characterized by comprising the following steps of firstly removing impurity particles in the environmental water by virtue of the water-quality treatment device, degassing the dissolved gas in the environmental water by virtue of the membrane degassing device and further discharging degassed environmental water; and finally further pumping and collecting the dissolved gas generated in the membrane degassing device into an gas cylinder by virtue of the vacuum collection device. The system disclosed by the invention has the characteristics of low cost, simple operation, high degassing efficiency, convenient carrying and maintenance, low weight, small size and the like, can be carried by single people and has almost no any application limitation on the extreme field environment so that the system is very suitable for extracting dissolved gas from the environmental water.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

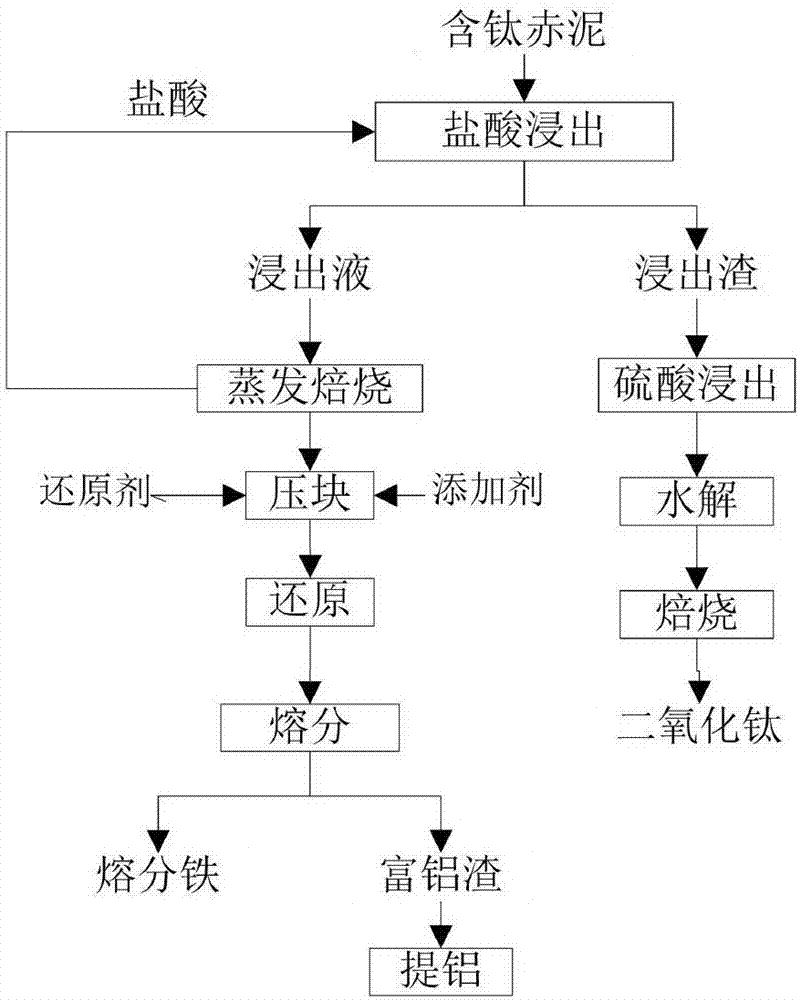

Method for treating titanium-containing red mud

The invention relates to a method for treating titanium-containing red mud. The method comprises the steps that after the titanium-containing red mud is leached through a hydrochloric acid solution, leaching residues and a leaching solution are obtained; and the treatment process of the leaching residues comprises the steps that the leaching residues are further leached by a sulfuric acid solution, and titanium dioxide is obtained through hydrolysis and roasting treatment. The treatment process of the leaching solution comprises the steps that the leaching solution is evaporated and roasted, a mixture is obtained, a reducing agent and an additive are added to the mixture, briquetting forming is conducted, a green ball is obtained, reduction and melt separation treatment are conducted on the green ball, and melt iron and aluminum-rich slag are obtained. By the adoption of the method for treating the titanium-containing red mud, effective separation and extraction of titanium, iron and aluminum can be achieved, the economic value of aluminum extraction from the aluminum-rich slag is increased, the energy consumption is lower, and the production cost is saved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

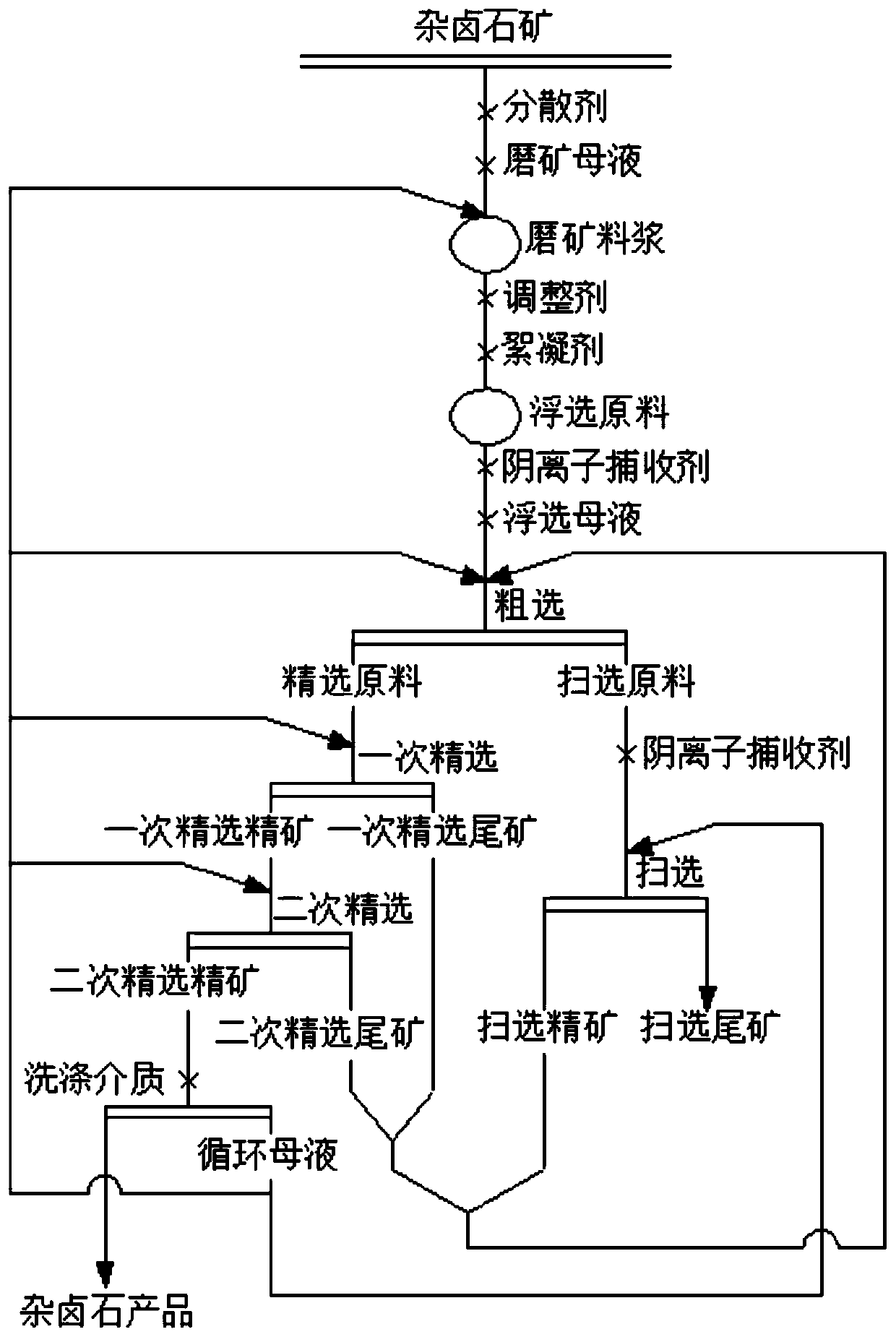

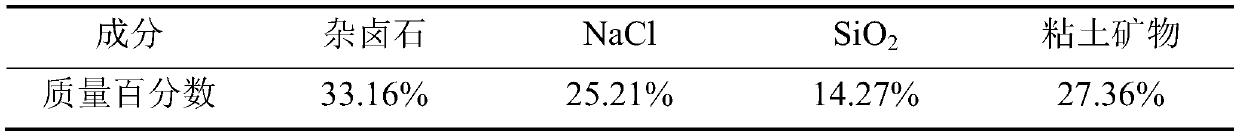

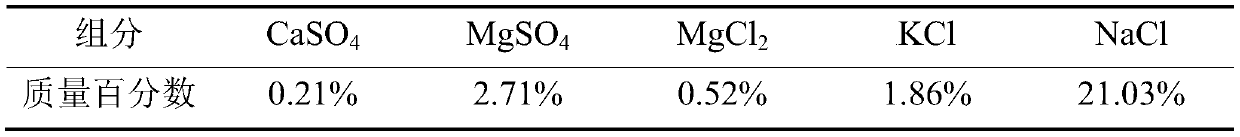

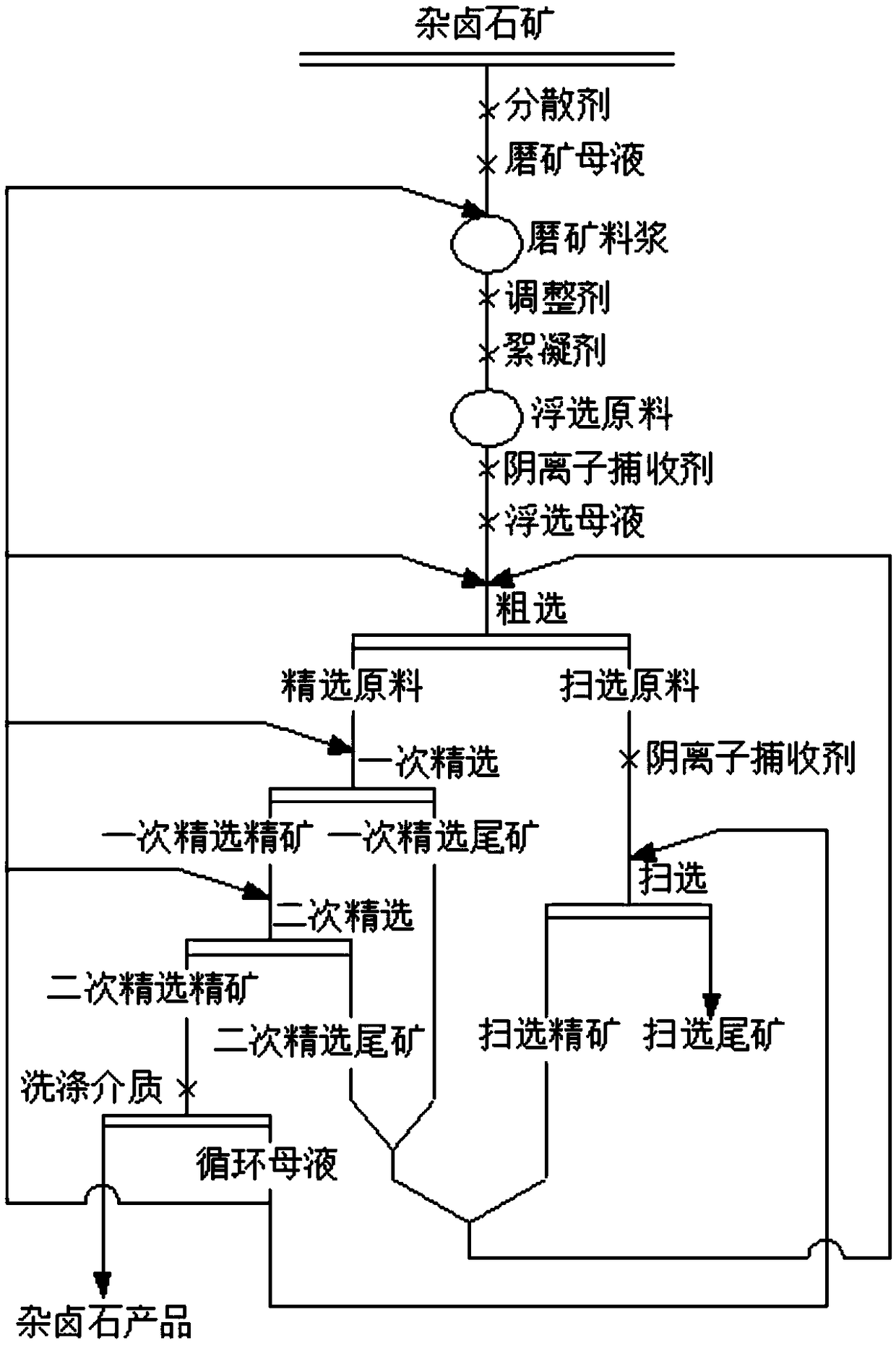

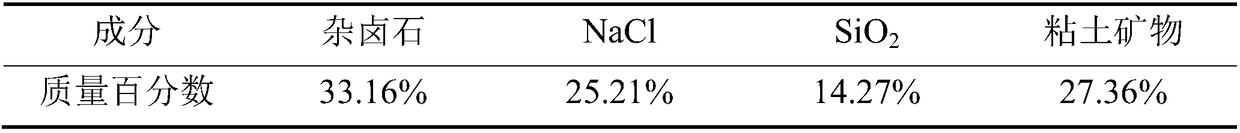

Method for extracting polyhalite from polyhalite ore containing gangue minerals

ActiveCN108714481BEffective separation and extractionSeparation and extraction are stable and effectiveDifferential sedimentationFlotationSlurryPolyhalite

The invention discloses a method for extracting polyhalite from polyhalite ore containing gangue mineral. The method comprises the steps that firstly, polyhalite ore containing gangue minerals containing halite and silicate and / or scrap salt is ground, a dispersing agent and ore grinding mother liquor are added, and ore grinding slurry is obtained; secondly, an adjusting agent and a flocculating agent are added in the ore grinding slurry, and a flotation raw material is obtained; thirdly, the flotation raw material is subjected to roughing in flotation mother liquor, and a selected raw material and a scavenging raw material are obtained; fourthly, the selected raw material is sequentially subjected to primary selection and secondary selection, secondary selected concentrates are obtained,the scavenging raw material is subjected to scavenging, and scavenging tailings are obtained; and fifthly, the flotation mother liquor and washing mother liquor are mixed to serve as a washing medium,solid-liquid separation is conducted after the secondary selected concentrates are washed, and polyhalite products are obtained. The method is suitable for separating and extracting the polyhalite from the polyhalite ore containing gangue minerals containing the silicate and / or the scrap salt and the like, and a technical scheme for utilizing the polyhalite in other types of polyhalite ore is further provided.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

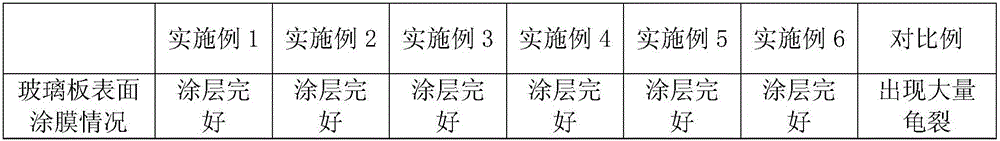

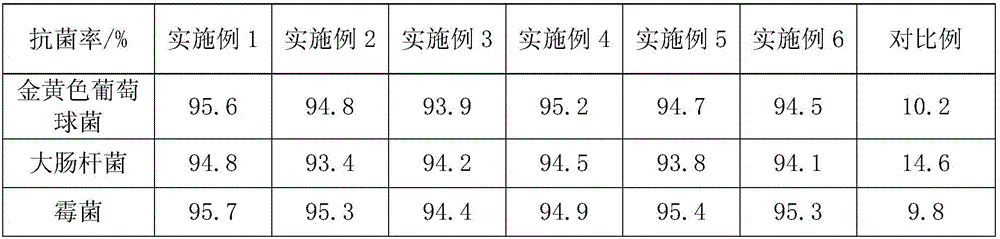

Sweat-resistant water-based polyurethane composite paint and method for preparing same

InactiveCN105670492AEffective separation and extractionHigh antibacterial activityAntifouling/underwater paintsPaints with biocidesWater basedPolyurethane dispersion

The invention provides sweat-resistant water-based polyurethane composite paint. The sweat-resistant water-based polyurethane composite paint comprises, by weight, 50-64 parts of water-based polyurethane dispersion, 0.5-0.7 part of dispersing agents, 0.3-0.6 part of wetting agents, 0.1-0.5 part of defoaming agents, 0.2-0.7 part of leveling agents, 3-4 parts of film-forming auxiliaries, 14-22 parts of fillers, 16-21 parts of deionized water, 0.6-1.5 parts of thickening agents, 1-1.5 parts of metal zinc driers, 0.5 part of vinyl triethoxysilane and 12-14 parts of composite sweat-resistant agents. The invention further provides a method for preparing the sweat-resistant water-based polyurethane composite paint. The sweat-resistant water-based polyurethane composite paint and the method have the advantage that the water-based polyurethane composite paint is excellent in sweat-resistant performance.

Owner:HUZHOU GUOXIN MATERIALS

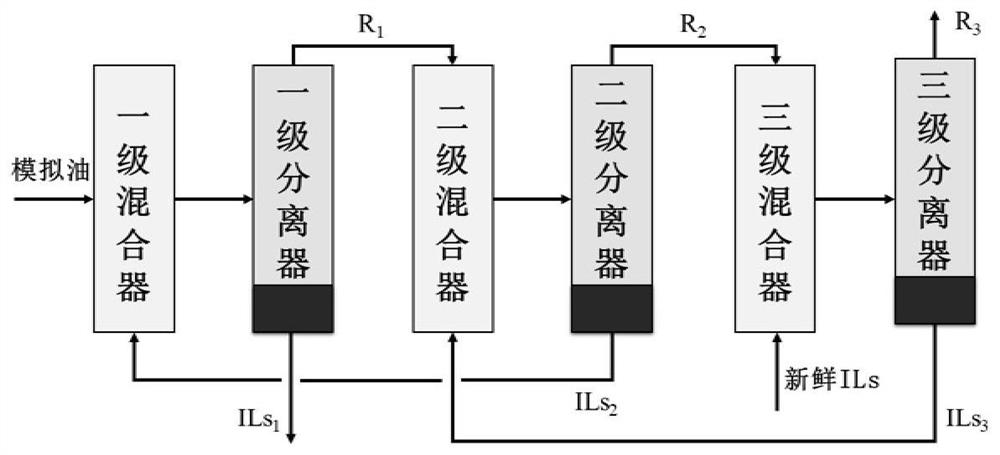

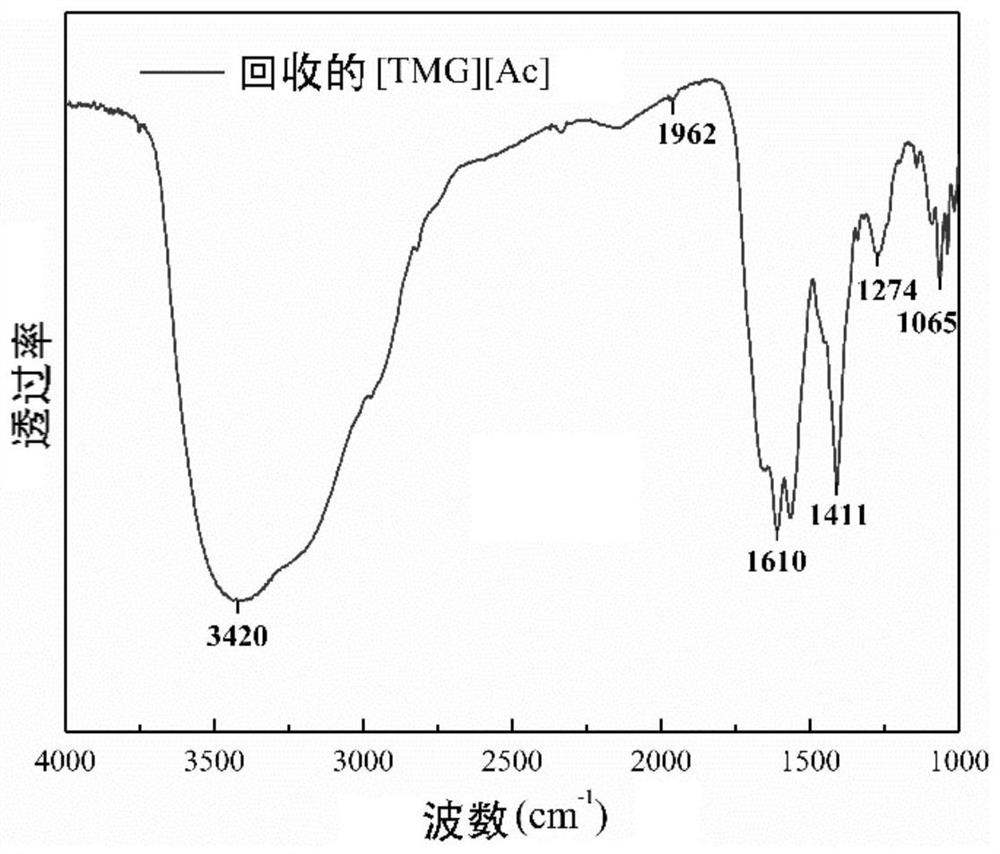

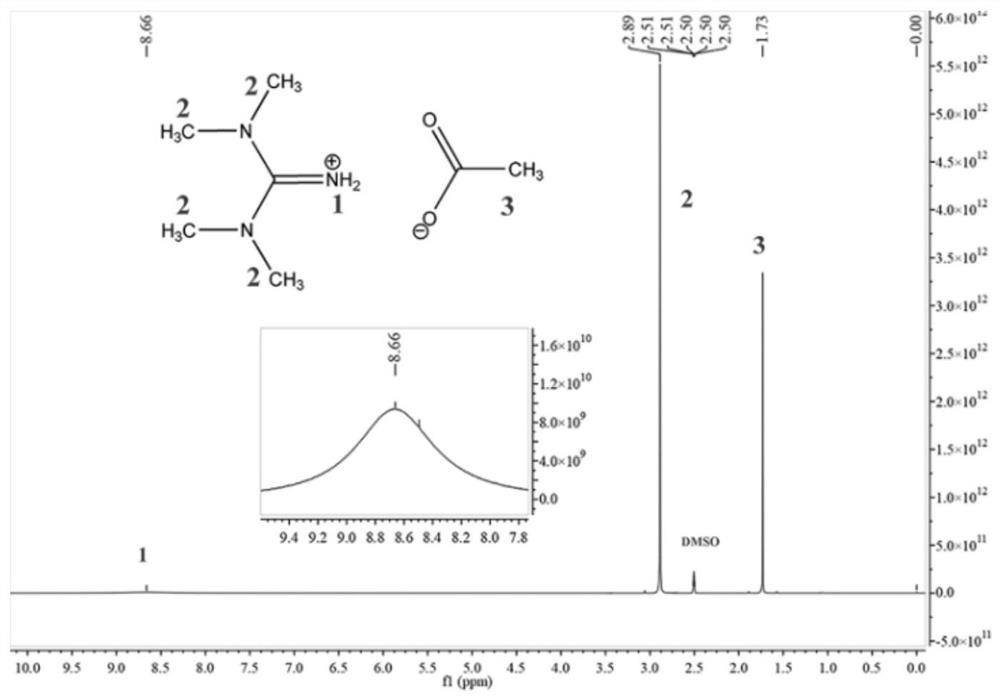

Method for extracting and separating neutral nitride in coal tar by utilizing non-toxic biodegradable ionic liquid

The invention provides a method for extracting and separating neutral nitrides in coal tar by utilizing non-toxic biodegradable ionic liquid. One or a combination of more than two of n-hexane, n-heptane, n-octane or n-dodecane is used as a solvent, and the non-toxic biodegradable tetramethylguanidyl ionic liquid is synthesized by a one-step method; and extracting and separating to obtain the neutral nitride through three-stage counter-current extraction, back extraction and reduced-pressure flash evaporation processes by taking the neutral nitride as an extracting agent. The tetramethylguanidyl ionic liquid is non-toxic, biodegradable, simple to synthesize, high in yield and purity, low in energy consumption, low in cost, small in waste liquid generation amount, green and environment-friendly. According to the method, the removal rate of high-boiling-point neutral nitrides in the wash oil and the anthracene oil is greatly increased, the excellent extraction and separation effect is achieved, and the extraction efficiency is high. The extraction and separation process is simple, and the device is reasonable; the nontoxic biodegradable tetramethylguanidyl ionic liquid is high in recovery rate and purity, can be recycled, and is safe and environment-friendly.

Owner:SHANDONG UNIV OF SCI & TECH

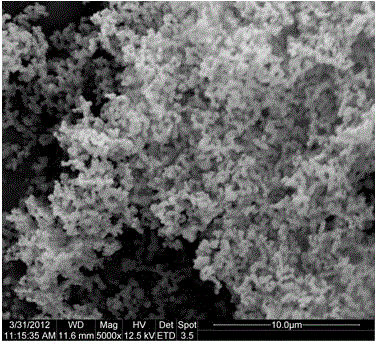

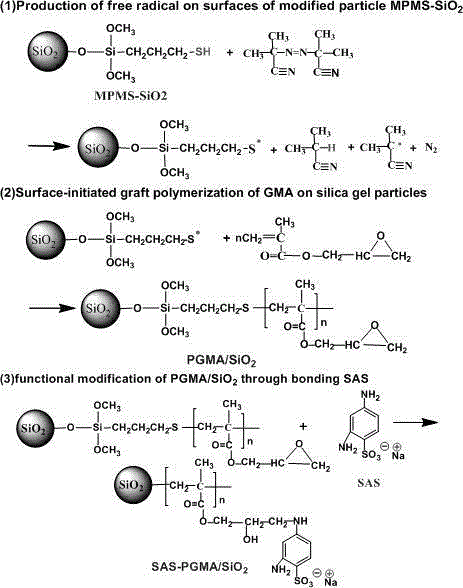

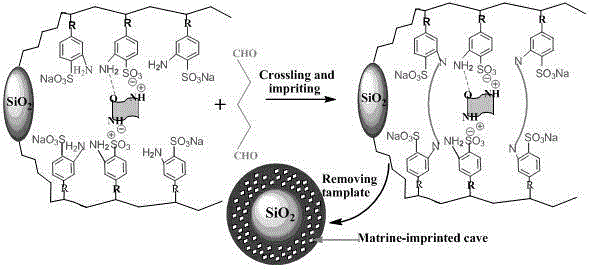

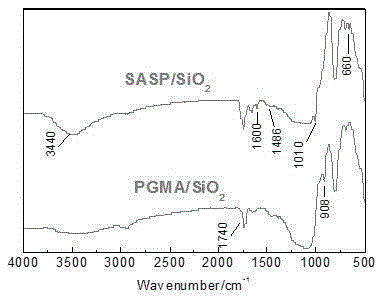

A kind of preparation method of matrine molecule surface imprinted polymer material

InactiveCN103601910BImprove mechanical propertiesSuitable for industrial productionOrganic chemistryOther chemical processesPolymer scienceMatrine

The invention provides a preparation method of a matrine molecular surface imprinted polymer material, which can be used to prepare a high-performance matrine molecular surface imprinted polymer material, which uses silica gel as a matrix, has good mechanical properties, and is suitable for industrial production; using matrine as a template molecule and glutaraldehyde as a cross-linking agent, a new molecular surface imprinting technology of "first graft polymerization-post-crosslinking imprinting" was used to prepare a matrine molecular surface imprinted polymer material. There are a large number of matrine imprinted holes distributed in the polymer thin layer, which shows specific recognition selectivity and excellent binding affinity for matrine, excellent elution performance, and good regeneration and recycling performance. This has obvious reference value for effectively separating and extracting pharmacologically active substances from plant tissues.

Owner:ZHONGBEI UNIV

A kind of process method of extracting protocatechuic acid from Yunnan Gui Ainaxiang

ActiveCN104098465BHigh purityEfficient separationCarboxylic compound separation/purificationChlorogenic acidElution

Belonging to the technical field of traditional Chinese medicine extraction, the invention discloses a technological method for extraction of protocatechuic acid from Blumea riparia (Bl.) DC. The method for preparation of a protocatechuic acid monomer consists of: water extraction, concentration, extraction, elution, and TLC preparation and purification. A compound B is determined as protocatechuic acid with a concentration of equal to or more than 99% by HPLC analysis, and is the protocatechuic acid monomer. The technological method for extraction of chlorogenic acid from Blumea riparia (Bl.) DC solves the problems of low preparation purity, small preparation quantity, complex preparation process, and difficult realization of industrialization production. By means of water extraction, concentration, extraction, elution and other processes, high extraction purity and a simple preparation process can be realized. Thus, the method is suitable for popularization, and meets the need of people for protocatechuic acid.

Owner:广西万寿堂药业有限公司

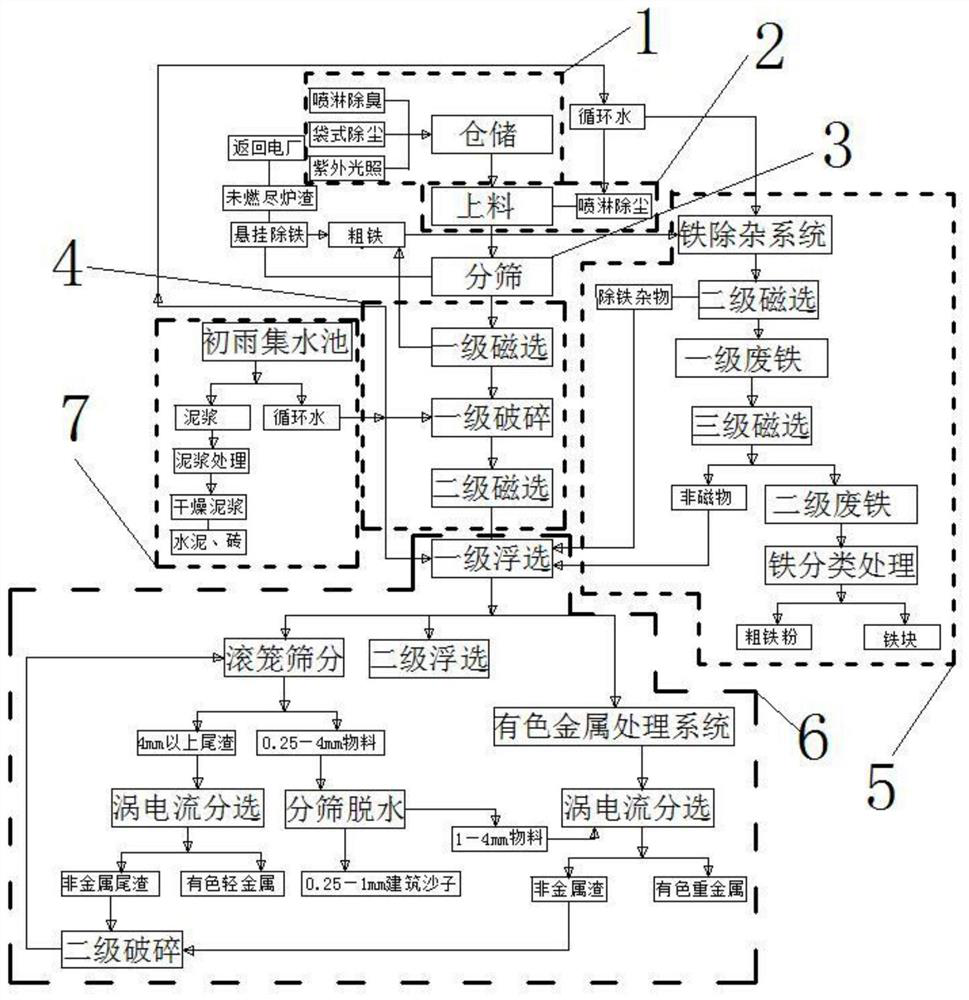

A wet-process resource utilization system for domestic waste incineration power plant slag

ActiveCN110420970BEffective separation and extractionRealize resource utilizationSludge treatmentSolid waste disposalWater treatment systemSlag

The invention discloses a wet method resource utilization system for domestic waste incineration power generation furnace slag, which comprises a slag storage system, a slag feeding system, a slag sorting system, a slag magnetic separation system, an iron treatment system, a non-magnetic metal treatment system, sewage Treatment system; a wet-process resource utilization system of domestic waste incineration power plant slag according to the present invention, which can effectively separate and extract various metals in the slag, realize resource utilization, and is environmentally friendly.

Owner:宇创环保产业有限公司

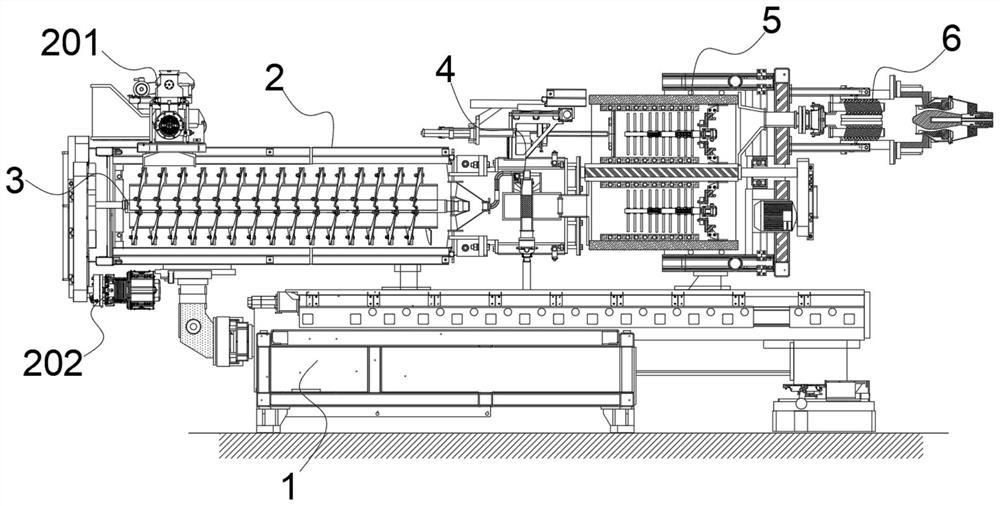

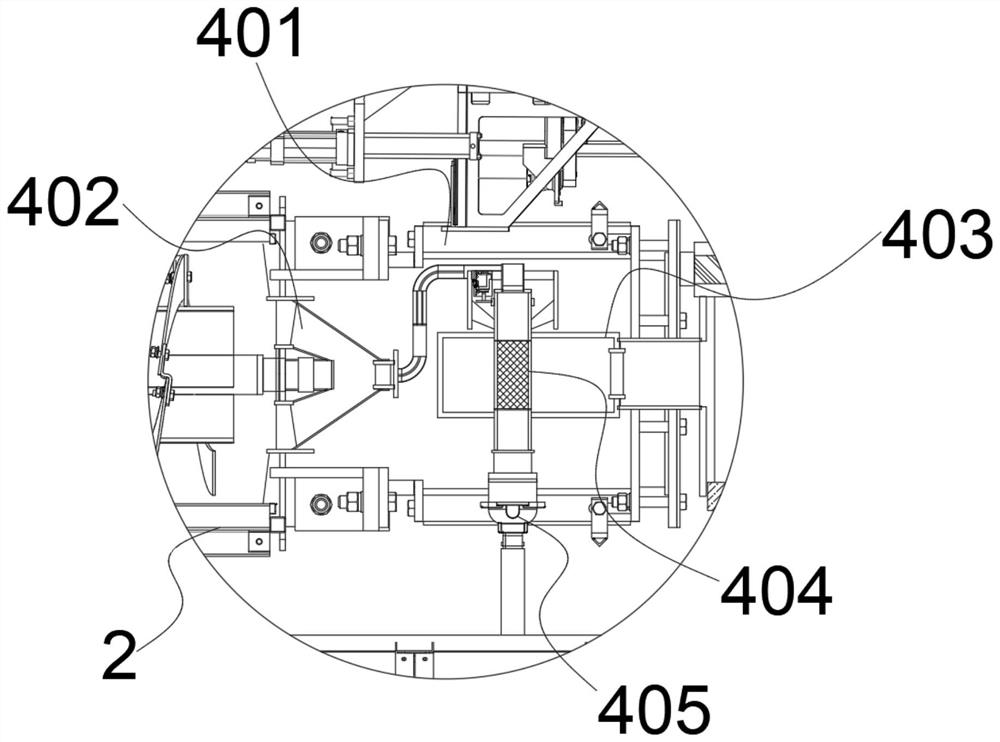

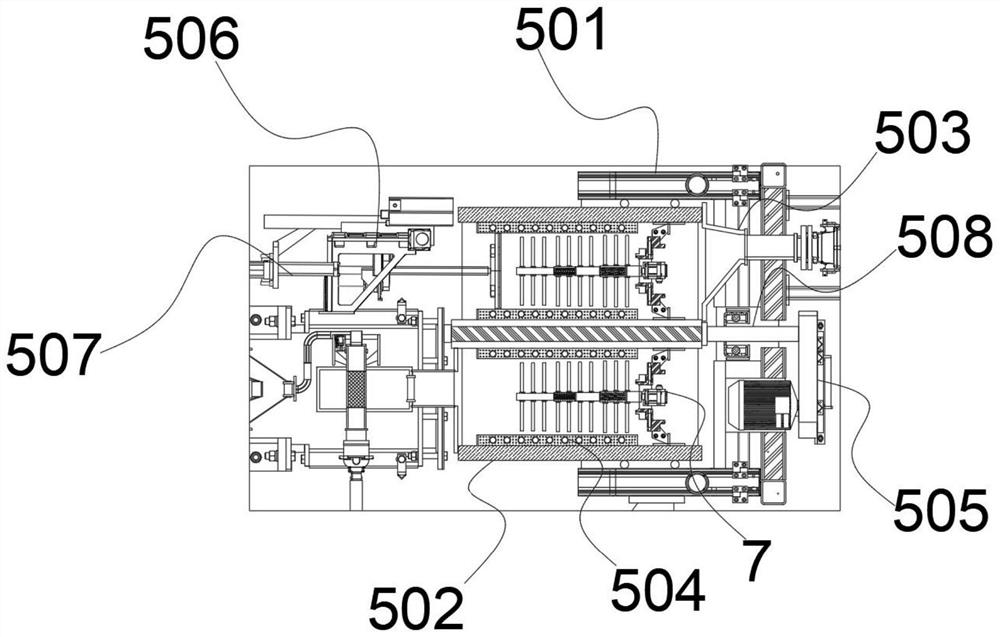

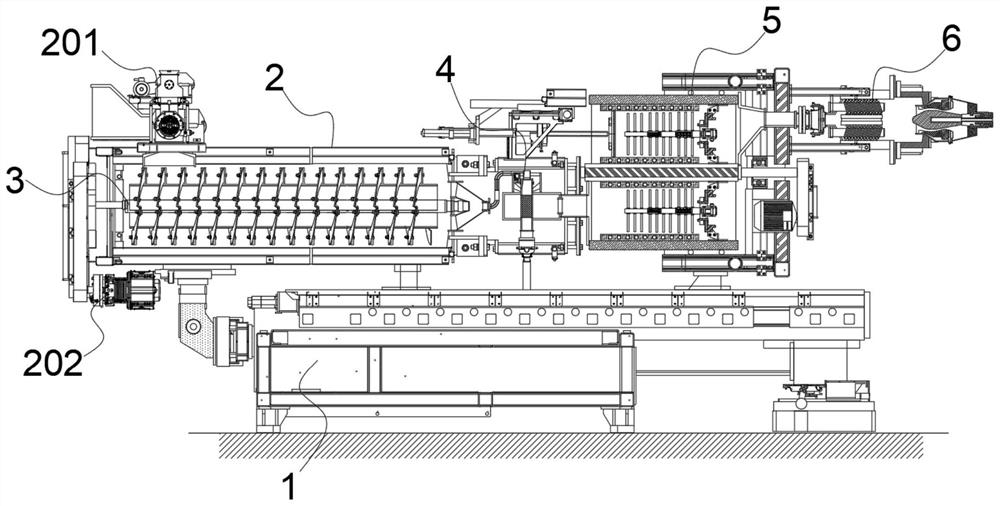

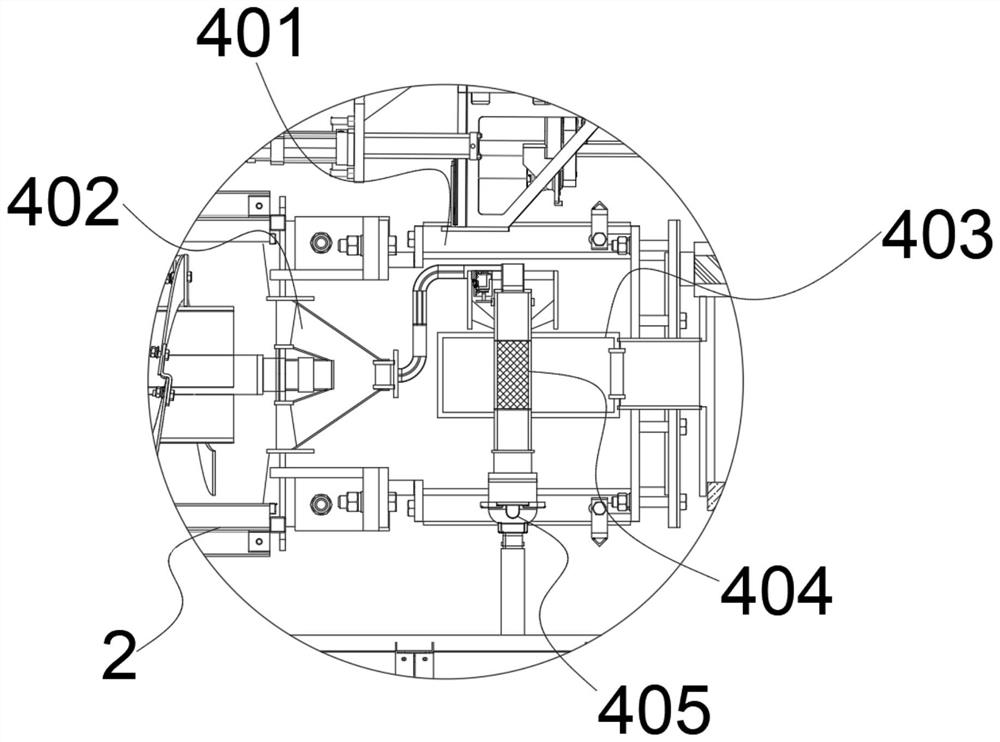

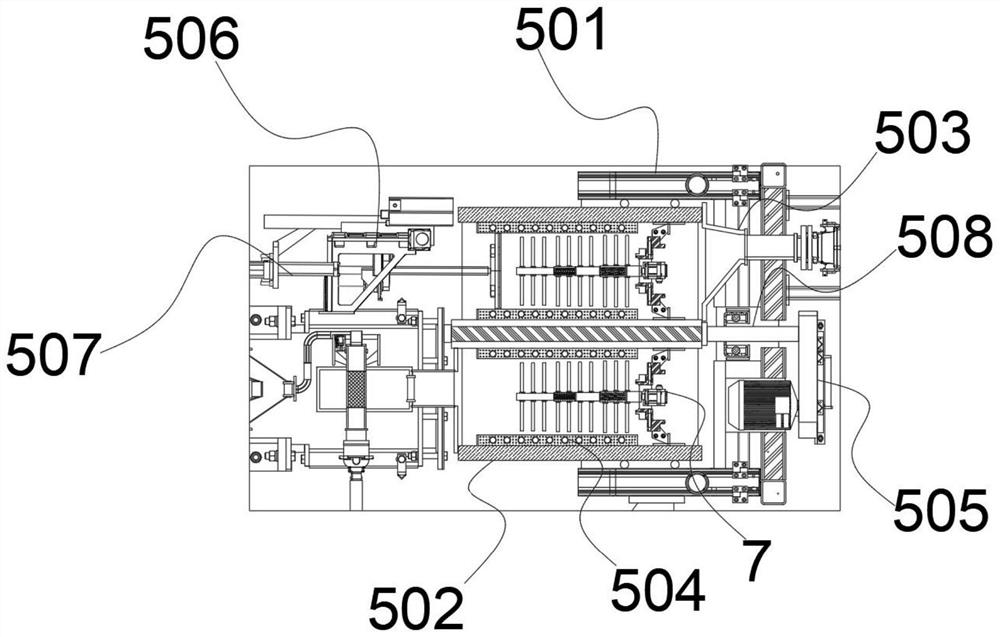

An extruder for the preparation of superhydrophobic polymer material composite microporous emulsion

ActiveCN113524610BEffective separation and extractionImprove extrusion qualityPolymer scienceHydrophobic polymer

The invention discloses an extruder for preparing a super-hydrophobic polymer material composite microporous emulsion. A tail extrusion assembly; wherein, a feeding cylinder member is laterally fixed on one side of the upper end surface of the mounting base through a fixing frame, and a feeding end seat is fixed through the upper end surface of the feeding cylinder member. A mixing and extruding shaft is arranged on the coaxial side that can rotate relatively inside, and one end of the mixing and extruding shaft is connected with a rotating motor arranged outside the feeding cylinder member to drive the feeding cylinder member away from the feeding end seat. A separation and discharge assembly is provided on one side, and the separation and discharge assembly separates and extracts the mixed preparation materials, so that the internal agglomerated particles are removed in time; the upper end face of the installation base is also provided with an inner heating assembly, and the inner heating assembly The upper end of one side is laterally connected with a tail extrusion component.

Owner:HEBEI NORMAL UNIV FOR NATTIES

Method for extracting residual abamectin

ActiveCN101838300BSolve difficult to extractEffective separation and extractionSugar derivativesSugar derivatives preparationAbamectinSilica gel

The invention relates to a method for extracting residual abamectin from crystallization mother liquor, which comprises the steps of removing ester impurities and further separating each component by using a C18 column or a silica gel column. The separation and extraction process is simple; the selected and used solvent is cheap, safe and environment-friendly, and meets the industrialized requirement; and the effective ingredient B1 has high yield and reaches about 90 percent.

Owner:浙江拜克生物科技有限公司

Extruder for preparing super-hydrophobic high polymer material composite microporous emulsion

ActiveCN113524610AEffective separation and extractionImprove extrusion qualityPolymer scienceElectric machine

The invention discloses an extruder for preparing a super-hydrophobic high polymer material composite microporous emulsion. The extruder comprises a mounting base, a material conveying barrel part, a mixing and extruding shaft, a feeding end seat, a separating and discharging assembly, an inner heating assembly and a tail extrusion assembly, wherein the material conveying barrel part is transversely and fixedly arranged on one side of the upper end face of the mounting base through a fixed frame, the feeding end seat is fixedly arranged on the upper end face of the material conveying barrel part in a penetrating mode, the mixing and extruding shaft is coaxially arranged in the material conveying barrel part in a relatively rotating mode, one end of the mixing and extruding shaft is connected with a rotating motor arranged outside the material conveying barrel part in a transmission manner, the separating and discharging assembly is arranged on one side, far away from the feeding end seat, of the material conveying barrel part, the separating and discharging assembly is used for carrying out separation and extraction on mixed preparation materials, so that agglomerated particles in the interiors of the materials are removed in time, the inner heating assembly is further arranged on the upper end face of the mounting base, and the upper end of one side of the inner heating assembly is transversely provided with the tail extrusion assembly in a communicating mode.

Owner:HEBEI NORMAL UNIV FOR NATTIES

Method for extracting polyhalite from polyhalite ore containing gangue mineral

ActiveCN108714481AEffective separation and extractionSeparation and extraction are stable and effectiveDifferential sedimentationFlotationScrapMother liquor

The invention discloses a method for extracting polyhalite from polyhalite ore containing gangue mineral. The method comprises the steps that firstly, polyhalite ore containing gangue minerals containing halite and silicate and / or scrap salt is ground, a dispersing agent and ore grinding mother liquor are added, and ore grinding slurry is obtained; secondly, an adjusting agent and a flocculating agent are added in the ore grinding slurry, and a flotation raw material is obtained; thirdly, the flotation raw material is subjected to roughing in flotation mother liquor, and a selected raw material and a scavenging raw material are obtained; fourthly, the selected raw material is sequentially subjected to primary selection and secondary selection, secondary selected concentrates are obtained,the scavenging raw material is subjected to scavenging, and scavenging tailings are obtained; and fifthly, the flotation mother liquor and washing mother liquor are mixed to serve as a washing medium,solid-liquid separation is conducted after the secondary selected concentrates are washed, and polyhalite products are obtained. The method is suitable for separating and extracting the polyhalite from the polyhalite ore containing gangue minerals containing the silicate and / or the scrap salt and the like, and a technical scheme for utilizing the polyhalite in other types of polyhalite ore is further provided.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

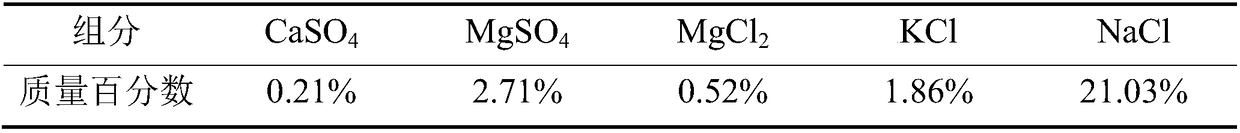

Purple rice natural dye

PendingCN112898801AEffective separation and extractionImprove extraction efficiencyNatural dyesChemistryRose balsam

The invention discloses a purple rice natural dye, which is prepared from the following ingredients in parts by weight: 30.00-45.00 parts of purple rice, 12.00-16.00 parts of iron ions, 8.00-13.00 parts of scindapsus aureus, 1.50-3.50 parts of alginic acid, 17.00-24.00 parts of fuchsin, 14.00-26.00 parts of roses, 3.50-7.50 parts of impatiens balsamina and 2.00-5.00 parts of potassium sorbate.

Owner:何瑞元

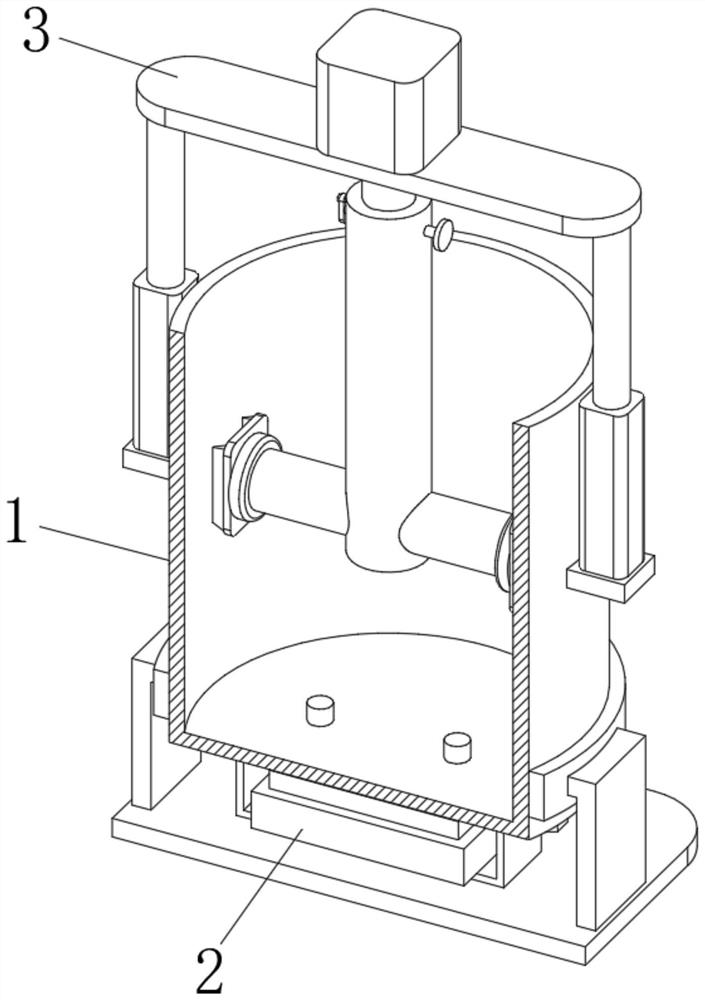

Method for purifying and recycling feed liquid from erythromycin produced by fermentation method

ActiveCN102199179BLow erythromycin contentEfficient captureSugar derivativesSugar derivatives preparationCentrifugationEnvironmental engineering

The invention belongs to the field of purifying and recycling pharmaceutical wastewater and specifically relates to a method for purifying and recycling a feed liquid from erythromycin produced by the fermentation method. The method provided by the invention is characterized by adsorbing Alpha-erythromycin in the feed liquid by using multistage resin; eluting the resin by using an eluant; adjusting the eluate with its pH value being from 7 to 10 and its water content being less than or equal to 20 wt%; precipitating and crystallizing erythromycin by using a precipitating agent or the hydrolysis control method, followed by cleaning and centrifugation; and drying the solid substance produced by the centrifugation step at a low temperature to obtain erythromycin. The method provided by the invention has advantages of low operation cost, convenient operation, reliable and flexible technology control, accomplishes the purpose of effectively obtaining the target substance by the solid phase extraction (adsorption) principle, effectively separates drug residuals in pharmaceutical factory wastewater from other contained substances to highly purify the wastewater, wherein the erythromycin content is lower than 1ppm and superior to national wastewater discharge standards, is friendly to environment, and produces no second pollution.

Owner:四川金本科技有限公司

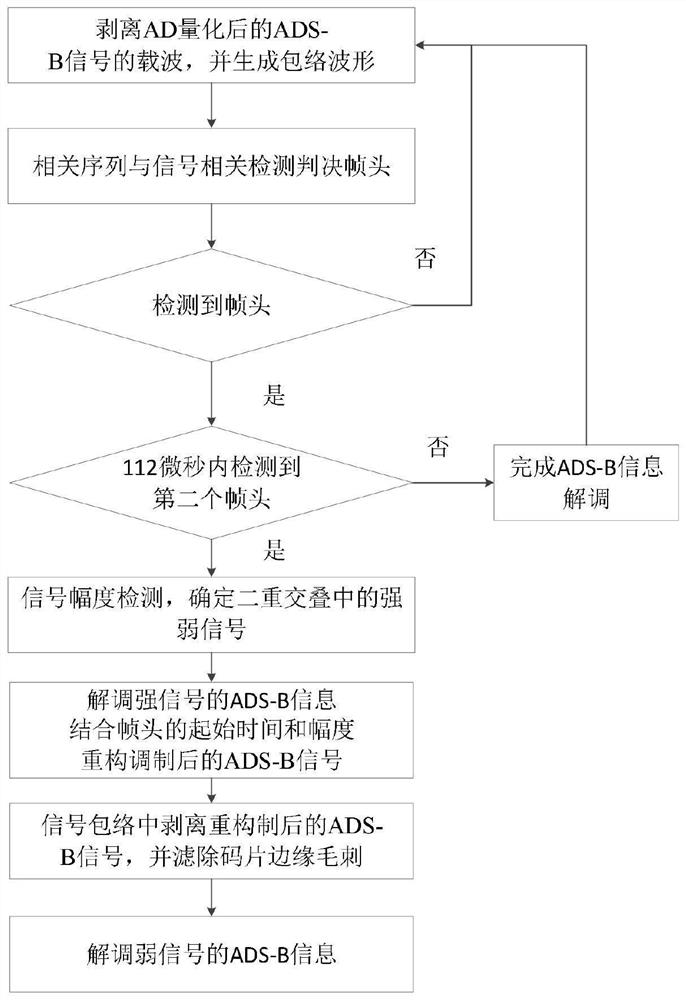

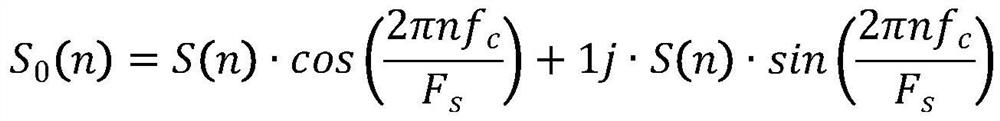

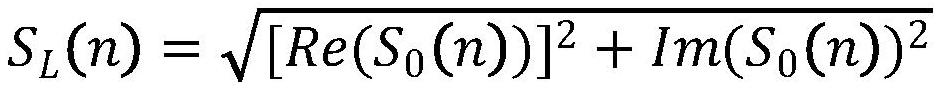

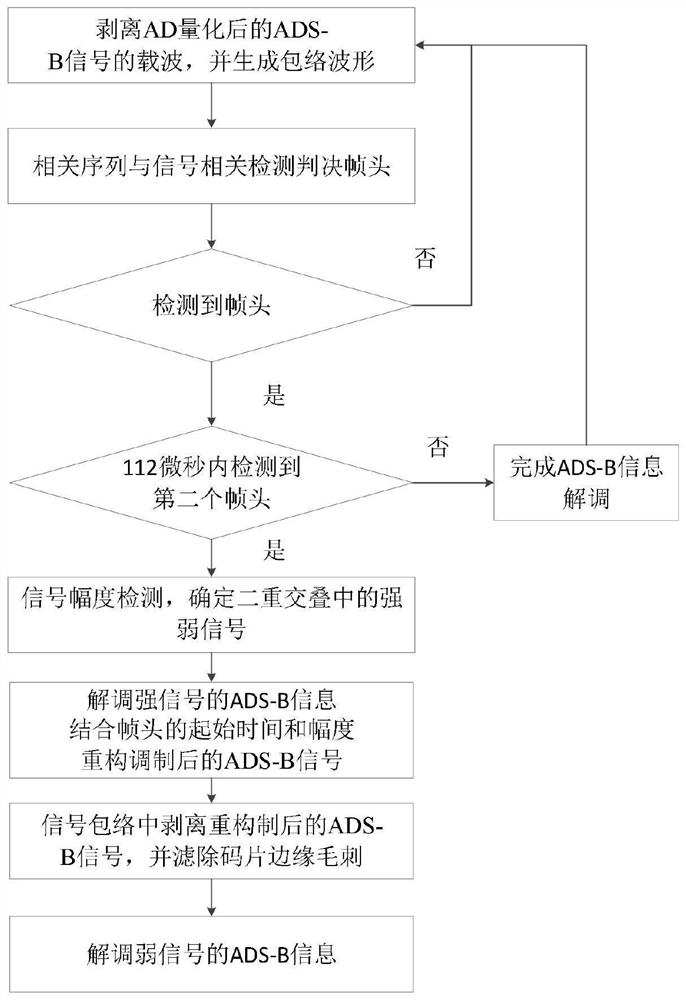

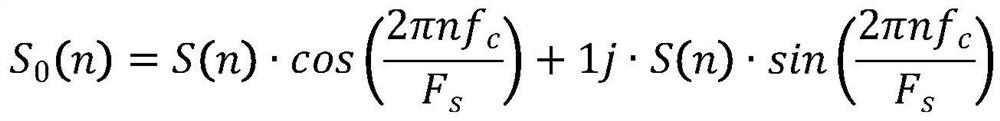

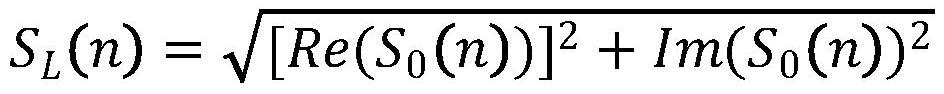

A separation method of ads-b signal overlapping reconstruction based on spaceborne scene

ActiveCN113223331BImproved demodulation probabilityReliable demodulationRadio transmissionAircraft traffic controlAlgorithmEngineering

The invention discloses an ADS‑B signal overlap reconstruction and separation method based on a spaceborne scene, and belongs to the technical field of signal processing. This method first detects and judges the overlapping signal, completes the start time detection of the strong ADS-B signal and the weak ADS-B signal in the double overlapping respectively, and intercepts signal sampling points comprising two overlapping signal lengths, and Complete the demodulation of the strong signal in the overlap, and then use the amplitude and information bits of the strong ADS‑B signal to reconstruct the signal modulation, strip the strong signal from the original waveform, and finally demodulate the weak ADS‑B signal, Get all ADS‑B information in overlapping signals. The method of the invention can be used in the field of ADS-B signal monitoring in space-borne scenarios, realize overlapping and separation of ADS-B signals in dense areas, and improve the success rate of information demodulation.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

A method for extracting Zn, Mn, Pb, Ag from zinc electrolysis anode slime

InactiveCN107245579BHigh economic valueEfficient separationProcess efficiency improvementLiquid wasteElectrolysis

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

ADS-B signal overlapping reconstruction separation method based on satellite-borne scene

ActiveCN113223331AImproved demodulation probabilityReliable demodulationRadio transmissionAircraft traffic controlSignal monitoringSignal processing

The invention discloses an ADS-B (Automatic Dependent Surveillance-Broadcast) signal overlapping reconstruction separation method based on a satellite-borne scene, and belongs to the technical field of signal processing. The method comprises the following steps of: firstly, detecting and judging overlapped signals, respectively completing starting time detection of a strong ADS-B signal and a weak ADS-B signal in double overlapping, intercepting a signal sampling point containing the length of two overlapped signals, completing demodulation of the strong signal in overlapping, then performing signal modulation and reconstruction by utilizing the amplitude and information bit of the strong ADS-B signal, and stripping the strong signal from the original waveform, and finally demodulating the weak ADS-B signal to obtain all ADS-B information in the overlapped signal. The method can be used in the field of satellite-borne scene ADS-B signal monitoring, ADS-B signal overlapping separation in a dense area is achieved, and the information demodulation success rate is increased.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com