Preparation method and application of kaempferol imprinted microsphere based on nanometer titanium dioxide

A technology of kaempferol and microspheres, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low separation and treatment efficiency and serious embedding of polymer microspheres, and achieve Effects of improving adsorption performance, regular particle shape, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

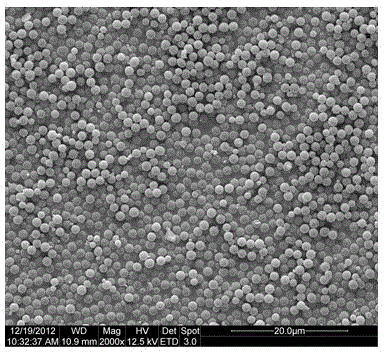

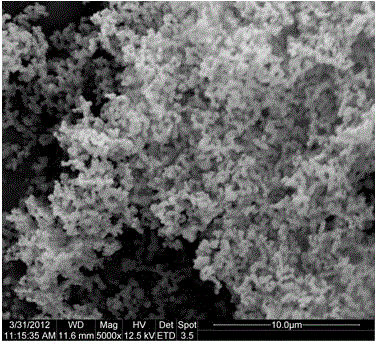

Embodiment 1

[0021] Dissolve 1mmol template molecule kaempferol and 4mmol functional monomer 4-VP into 40ml porogen acetonitrile, ultrasonically disperse for 10min, then add 20mg TiO 2 , stirred mechanically for 2 hours, passed nitrogen for 20 minutes to deoxidize, then added 20 mmol of cross-linking agent EDMA, passed nitrogen for 20 minutes to deoxidize, added 50 mg of initiator AIBN, sealed in a vacuum state, and reacted in an oil bath at 63°C for 24 hours to obtain a solid polymer. Pass the synthesized imprinted polymer through a 200-mesh sieve, use methanol:acetic acid (V / V, 9:1) as the extraction solution, extract the polymer particles for 72 hours, and then use pure methanol for Soxhlet extraction for 24 hours, equilibrate Remove acetic acid. The obtained polymer was dried in a vacuum drying oven at 60° C. for 24 hours to obtain a molecularly imprinted polymer on the surface of kaempferol. Prepared without TiO 2 The kaempferol molecularly imprinted polymer was used as a blank comp...

Embodiment 2

[0026] Dissolve 1mmol template molecule kaempferol and 6mmol functional monomer AM into 30ml porogen acetonitrile, ultrasonically disperse for 10min, then add 30mg TiO 2, stirred mechanically for 2 hours, passed nitrogen for 20 minutes to deoxidize, then added 30 mmol of cross-linking agent EDMA, passed nitrogen for 20 minutes to deoxidize, added initiator AIBN 100 mg, sealed in a vacuum state, and reacted in an oil bath at 63°C for 24 hours to obtain a solid polymer. Pass the synthesized imprinted polymer through a 200-mesh sieve, use methanol:acetic acid (V / V, 9:1) as the extraction solution, extract the polymer particles for 72 hours, and then use pure methanol for Soxhlet extraction for 24 hours, equilibrate Remove acetic acid. The obtained polymer was dried in a vacuum drying oven at 60° C. for 24 hours to obtain a molecularly imprinted polymer on the surface of kaempferol.

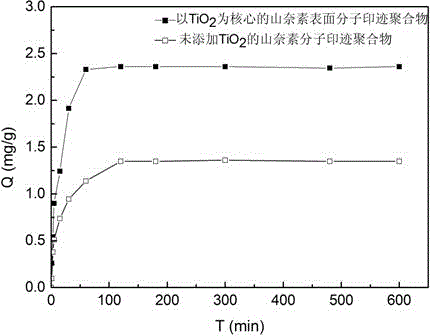

[0027] (1) Adsorption kinetics experiment

[0028] Weigh 50mg of the eluted surface molecularly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com