A drying device for bentonite cat litter

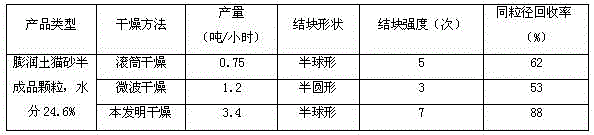

A drying device and technology of bentonite, applied in the directions of drying gas arrangement, drying solid materials, drying, etc., can solve the problems of easily destroying the particle shape of bentonite cat litter, unfavorable large-scale, mass production, and large radiation of operators, and achieves the goal of achieving particle size. The effect of regular shape, stable product quality and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

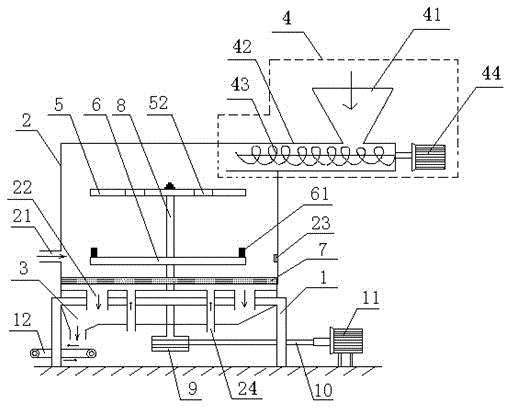

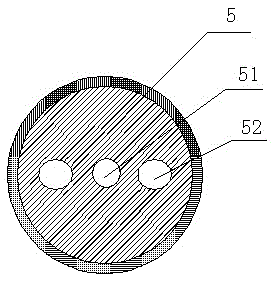

[0023] see figure 1 Disclosed is a drying device for bentonite cat litter, comprising a base 1, a drying and breaking cylinder 2, a discharge hopper 3 and a feeding mechanism 4. The drying and breaking cylinder 2 is arranged above the base 1 , the discharge hopper 3 is arranged under the base 1 , and the feeding mechanism 4 is arranged on one side of the upper wall of the drying and breaking cylinder 2 .

[0024] The feeding mechanism 4 includes a feeding hopper 41 , a feeding cylinder 42 , a feeding screw 43 and a first motor 44 . Feed hopper 41 is arranged on the top of one end of feeding cylinder 42, and its outlet communicates with the cylinder chamber of feeding cylinder 42, and one end of feeding cylinder 42 is closed shape, and the other end communicates with the cylinder chamber of drying and breaking up cylinder 2; The feeding screw 43 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com