A kind of steel slag aggregate synchronous crushed stone seal layer material and construction method for highway maintenance

A technology for synchronous gravel sealing and road maintenance, which is applied to roads, roads, on-site coagulation pavements, etc., can solve the problems of high dependence on high-quality stone materials, difficult and harmless disposal of steel slag, and reduce road maintenance costs , excellent water resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: After mixing 90kg of steel slag aggregate, 10kg of asphalt, and 0kg of filler, steel slag aggregate synchronous gravel seal material for highway maintenance is obtained;

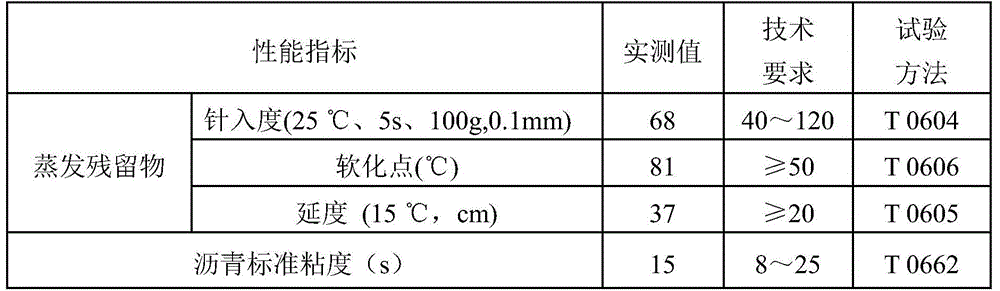

[0027] The asphalt is diluted asphalt.

Embodiment 2

[0028] Embodiment 2: 85kg of steel slag aggregate, 10kg of asphalt, and 5kg of filler are mixed to obtain steel slag aggregate synchronous gravel seal material for highway maintenance;

[0029] The filler is composed of 10kg of limestone powder and 90kg of semi-dry flue gas desulfurization ash;

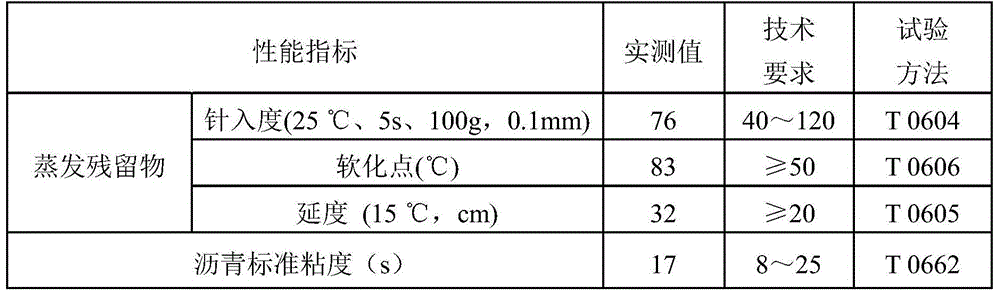

[0030] Asphalt is emulsified asphalt or rubber modified asphalt.

Embodiment 3

[0031] Embodiment 3: 90kg of steel slag aggregate, 5kg of asphalt, and 5kg of filler are mixed to obtain steel slag aggregate synchronous gravel seal material for highway maintenance;

[0032] The binder is made by mixing 90kg of limestone powder and 10kg of semi-dry flue gas desulfurization ash;

[0033] The asphalt is SBS modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com