Device and method for recovery, separation and purification of aluminum-tin alloy through vacuum continuous crystallization

A technology for crystallization separation and recycling of aluminum, applied in the direction of improving process efficiency, can solve the problems of easy oxidation of aluminum, inability to handle aluminum-tin alloy, insufficient temperature range of crystallizer, etc., and achieves low cost, high universality of raw materials, and easy operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

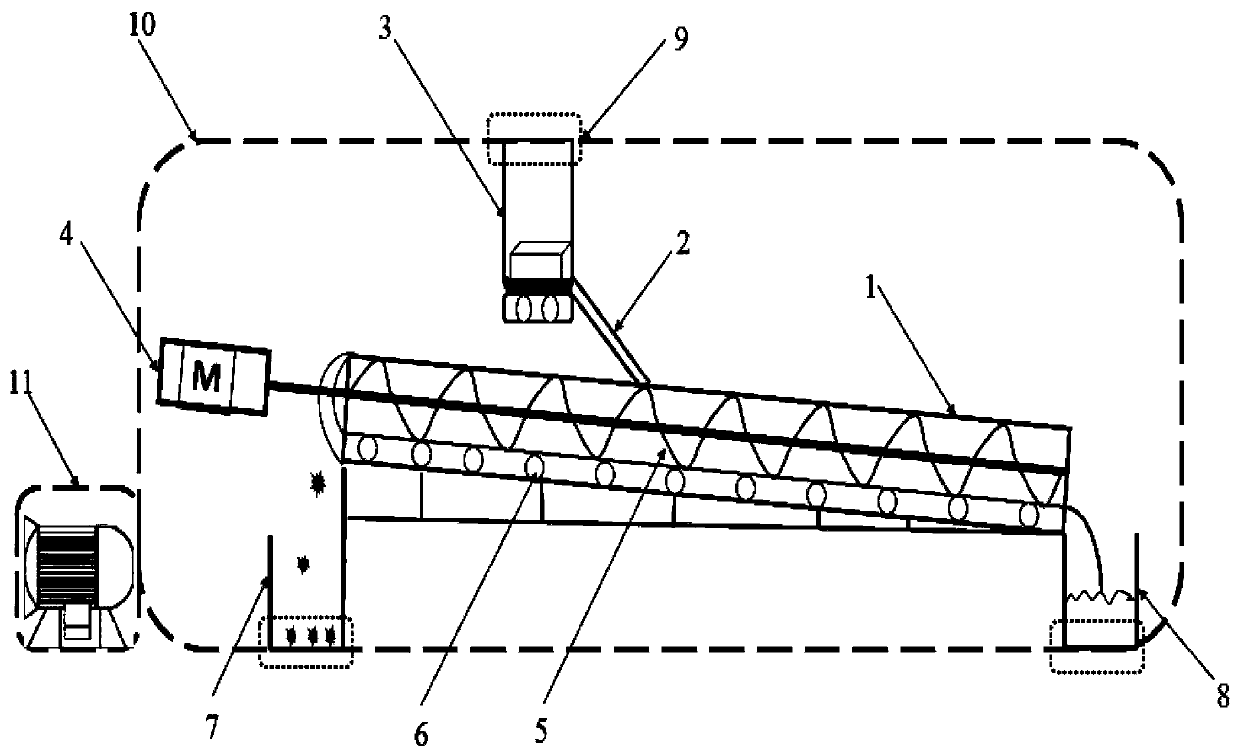

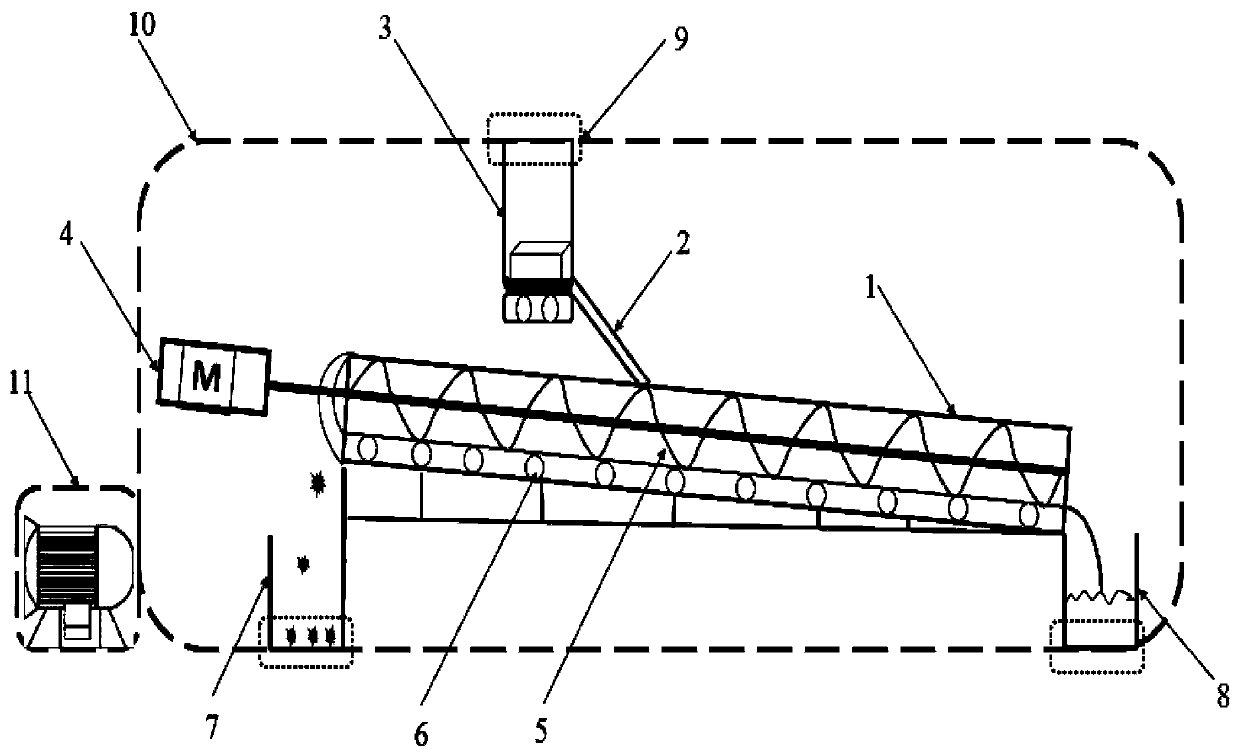

[0036] A device for vacuum continuous crystallization, separation, purification, and recovery of aluminum-tin alloys, including a casing, a vacuum pump, a U-shaped crystallization tank, a melting pot, a melting pot, and a crystal pot. The vacuum pump communicates with the inner cavity of the casing. The vacuum pump is used to evacuate to realize the vacuum environment of the inner cavity. The U-shaped crystallization tank, melting material pot, melt pot, and crystal pot are all set in the inner cavity of the shell. The U-shaped crystallization tank is arranged obliquely. The high end is the tank head and the low end is the tank tail. The inclination angle of the U-shaped crystallization tank It is 2°-7°, the crystal pot is connected with the groove head, and the melt pot is connected with the groove tail. There are several heating elements at the bottom of the U-shaped crystallization tank. The temperature at the head of the tank is higher than that at the end of the tank. The...

Embodiment 2

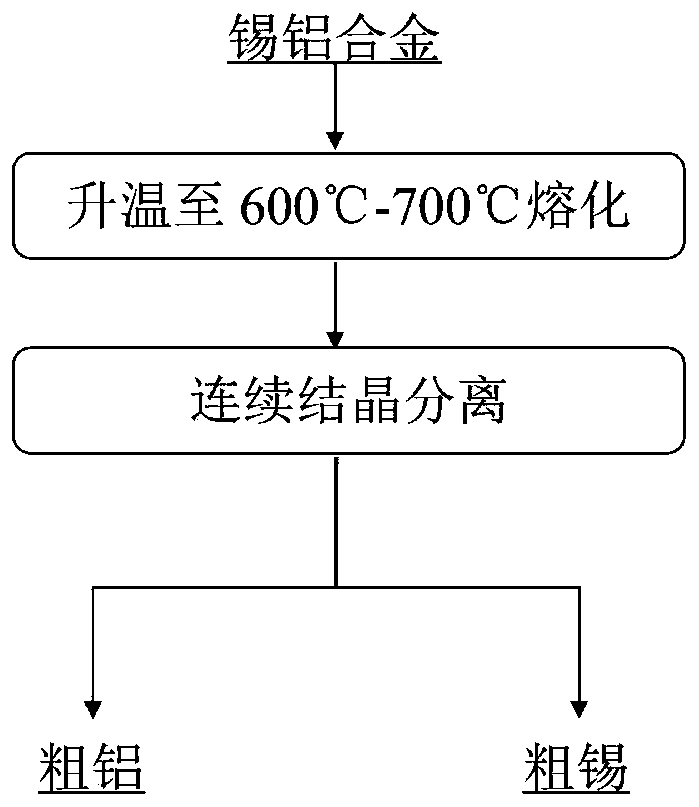

[0040] This embodiment is the application of the above-mentioned embodiment 1, a method for vacuum continuous crystallization, separation, purification and recovery of aluminum-tin alloys, including:

[0041] Step 1. Turn on the vacuum pump and the circulating water machine. First, 500 g of aluminum-tin alloy (wherein the mass fraction of tin is 20%) is heated to 650° C. under vacuum conditions (vacuum degree is 500 Pa) and fully melted.

[0042] Step 2. The completely melted aluminum-tin alloy melt flows into the U-shaped crystallization tank through the chute. The temperature range is 228°C-660°C. The U-shaped crystallization tank has an inclination angle of 3°, and continuous crystallization and separation are carried out under the drive of the screw ( The rotation speed of the screw is 20r / min), and the molten metal flowing into the U-shaped crystallization tank flows to the low-temperature area for crystallization due to gravity, and the crystal is transported by the screw...

Embodiment 3

[0045] This embodiment is the application of the above-mentioned embodiment 1, a method for vacuum continuous crystallization, separation, purification and recovery of aluminum-tin alloys, including:

[0046] Step 1. Turn on the vacuum pump and circulating water machine. First, 500 g of aluminum-tin alloy (wherein the mass fraction of tin is 30%) is heated up to 630° C. under vacuum condition (vacuum degree is 500 Pa) and fully melted.

[0047] Step 2. The completely melted aluminum-tin alloy melt flows into the U-shaped crystallization tank through the chute. The temperature range is 228°C-660°C. The U-shaped crystallization tank has an inclination angle of 3°, and continuous crystallization and separation are carried out under the drive of the screw ( The rotation speed of the screw is 10r / min), and the metal melt flowing into the U-shaped crystallization tank flows to the low-temperature area for crystallization due to gravity, and the crystal is transported by the screw to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com