A kind of preparation method of matrine molecule surface imprinted polymer material

A polymer material, surface imprinting technology, applied in chemical instruments and methods, organic chemistry, other chemical processes, etc., can solve the problems of affecting the efficiency of solid-phase extraction, poor product performance, complicated preparation process, etc., and achieve good regeneration and circulation. The effect of using performance, excellent binding affinity, and excellent elution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

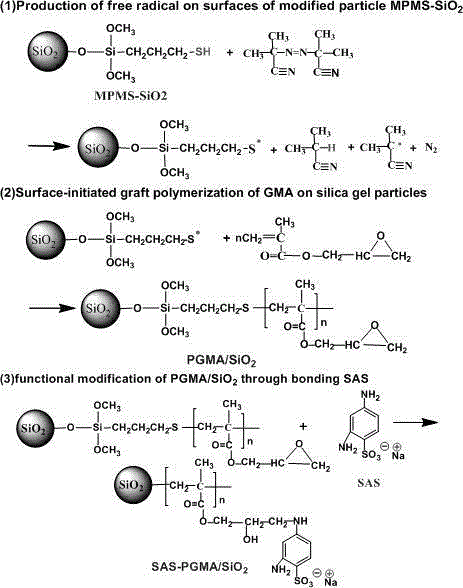

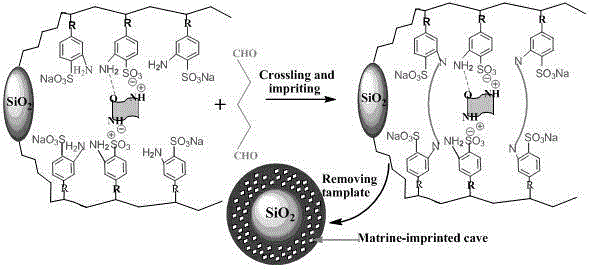

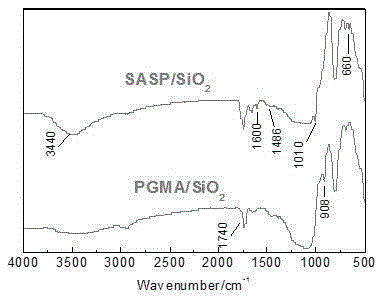

[0026] A method for preparing a matrine molecular surface imprinted polymer material of the present invention, the specific steps are as follows: Step 1, preparing functional graft particles SAS-PGMA / SiO 2 :

[0027] ①Add 2.5g of activated silica gel, 125ml of toluene solvent and 2.5mL of coupling agent γ-mercaptopropyltrimethoxysilane (KH-590) into a four-neck flask equipped with an electric stirrer, condensing reflux tube and thermometer, React at 110°C for 12 hours. After the reaction is over, filter with suction. The product particles are washed with toluene, then repeatedly washed with ethanol, and dried in vacuum to obtain modified silica gel particles MPMS-SiO with mercapto groups on the surface. 2 ;

[0028] ②In a four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 1.2g of modified particles MPMS-SiO 2 , then add 70mL of DMF and 9.9-10.0mL monomer GMA, pass nitrogen for 30min to remove the air in the system, raise the temper...

Embodiment 2

[0035] Step 1, preparation of functional graft particles SAS-PGMA / SiO 2 :

[0036] ①Add 3.0g of activated silica gel, 130ml of toluene solvent and 3.0mL of coupling agent γ-mercaptopropyltrimethoxysilane (KH-590) into a four-neck flask equipped with an electric stirrer, condensing reflux tube and thermometer, React at 110°C for 12 hours. After the reaction is over, filter with suction. The product particles are washed with toluene, then repeatedly washed with ethanol, and dried in vacuum to obtain modified silica gel particles MPMS-SiO with mercapto groups on the surface. 2 ;

[0037] ②In a four-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 1.5g of modified particle MPMS-SiO 2 , then add 70mL of DMF and 10.0mL monomer GMA, pass nitrogen for 30min to remove the air in the system, raise the temperature of the system to 55°C, then add 0.0874g of initiator AIBN, and carry out graft polymerization under constant temperature stirring; A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com