Method for recycling platinum group metal from waste catalysts

A technology for platinum group metals and waste catalysts, which is used in the field of platinum group metal recovery and platinum group metal recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

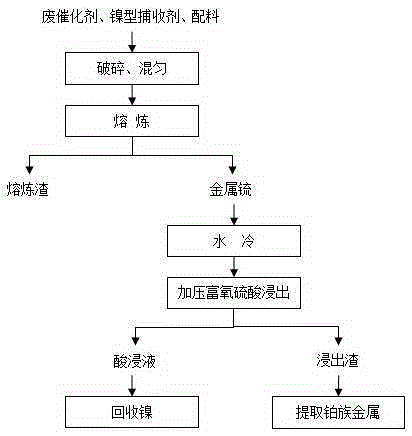

Image

Examples

Embodiment 1

[0031] Weigh out Al 2 o 3 600g of waste automobile catalyst with a mass fraction of 41.90%, 1005.6g of calcium oxide, 754.2g of silicon dioxide, and 3600g of nickel-type catalyst (the nickel-type collector is high-nickel matte obtained from smelting nickel sulfide ore, and the high-nickel matte is separated by grinding and flotation. After copper and nickel, nickel concentrate containing 75% nickel sulfide and 18% nickel oxide can be obtained), which is crushed to 100 mesh by jaw crusher, mixed evenly, placed in a crucible, and heated to 1400°C in a muffle furnace. And constant temperature 1h. After cooling and separating the slag phase, the contents of platinum, palladium, and rhodium in the metal matte are 0.0382g, 0.6300g, and 0.0703g, respectively. Based on this calculation, the achievable capture rates are 99.48%, 99.53%, and 97.64%, respectively.

[0032] Heat up the metal matte again, and control the temperature to 1210°C for water cooling. Slurry the collected metal...

Embodiment 2

[0034] Weigh out Al 2 o 3600g of waste petrochemical catalyst with a mass fraction of 44.10%, 1587.6g of calcium oxide, 1323.0g of silicon dioxide, and 5400g of nickel-type catalyst (nickel-type collector is high-nickel matte obtained from nickel sulfide ore smelting, in which the high-nickel matte is milled and floated After separating copper and nickel, nickel concentrate containing 85% nickel sulfide and 11% nickel oxide can be obtained), which is crushed to 60 mesh by jaw crusher, mixed evenly, placed in a crucible, and heated to 1450°C in a muffle furnace , and keep the temperature for 1h. After cooling and separating the slag phase, the contents of platinum, palladium, and rhodium in the metal matte are 0.1149g, 0.1253g, and 0.0561g, respectively. Based on this calculation, the achievable capture rates are 99.22%, 99.44%, and 96.39%, respectively.

[0035] Heat up the metal matte again, and control the temperature to 1250°C for water cooling. Slurry the collected meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com