Extruder for preparing super-hydrophobic high polymer material composite microporous emulsion

A water polymer, extruder technology, applied in the field of super-hydrophobic high material preparation equipment, can solve problems such as ineffective mixing, influence of the quality and efficiency of the emulsion extruder, uneven heating of materials, etc., to improve extrusion The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

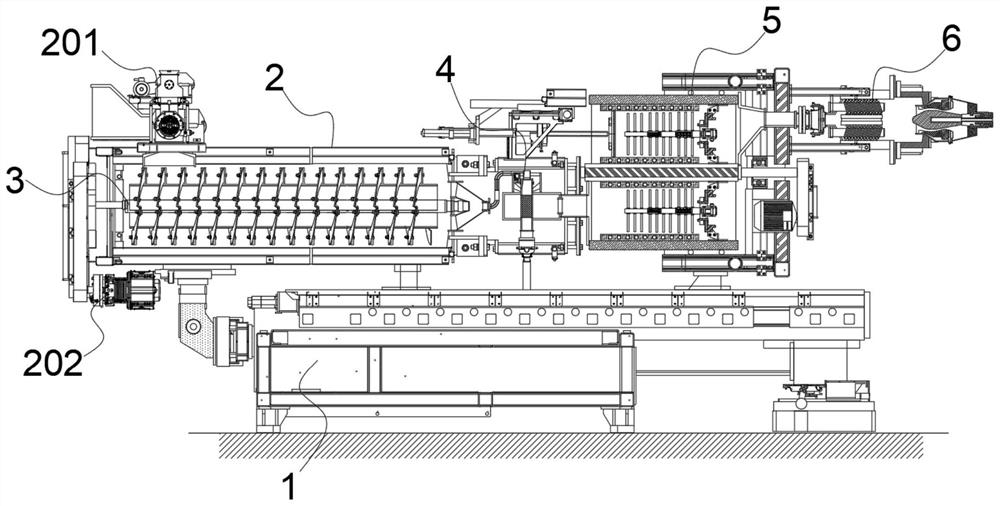

[0036] see figure 1 , in an embodiment of the present invention, an extruder for preparing a superhydrophobic polymer material composite microporous emulsion, which includes a mounting base 1, a feeding cylinder 2, a mixing extrusion shaft 3, a feed end seat 201, a separation The discharge assembly 4, the internal heating assembly 5 and the tail extrusion assembly 6; wherein, one side of the upper end surface of the installation base 1 is laterally fixed with a delivery cylinder part 2 through a fixing frame, and the upper end surface of the delivery cylinder part 2 runs through A feed end seat 201 is fixed, which is used to feed in various preparation materials. A mixing extrusion shaft 3 is arranged coaxially in the material delivery cylinder 2 and is relatively rotatable. One end of the mixing extrusion shaft 3 is connected to the set The rotary motor 202 outside the feeding cylinder part 2 is connected and driven;

[0037] The mixing extrusion shaft 3 is used to uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com