Method for extracting polyhalite from polyhalite ore containing gangue mineral

A technology of gangue minerals and polyhalite mines, applied in chemical instruments and methods, wet separation, selective deposition methods, etc., can solve the effects of polyhalite flotation, acid salts and detrital salts and other gangue minerals There are no reports on the development and utilization of polyhalite mines, etc., to achieve the effect of reducing extraction costs and increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

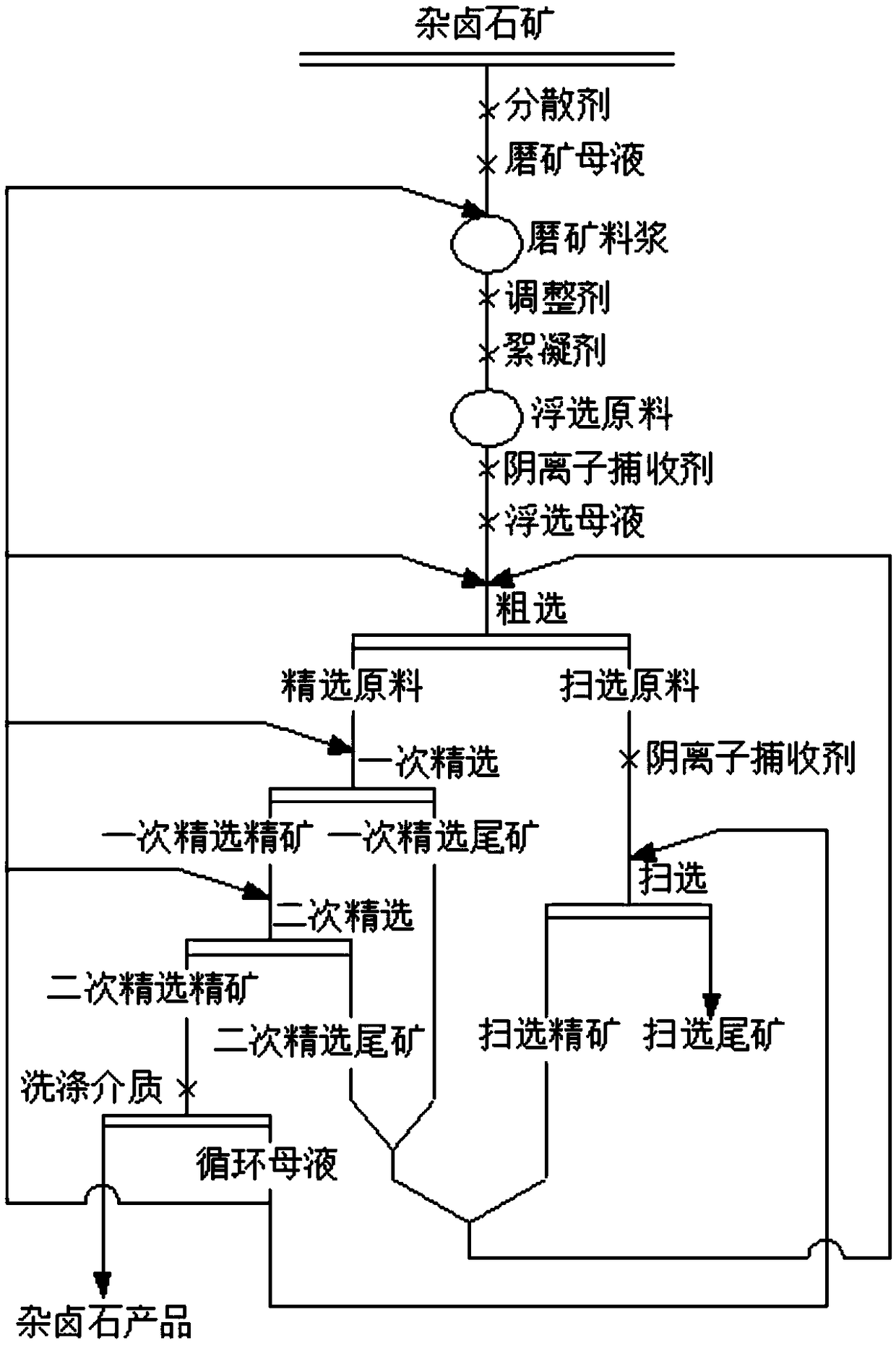

[0058] In this embodiment, first, the low-grade polyhalite ore containing gangue minerals such as silicate, detrital salt, and halite is ground to -200 mesh (-0.074mm) and accounts for 80.26 wt%. For rod milling, sodium metaphosphate is added as a dispersant according to the addition amount of 60g / 1t polyhalite ore, the mass concentration of ore grinding is 55%, and the grinding medium is saturated mother liquor to obtain ore abrasive slurry.

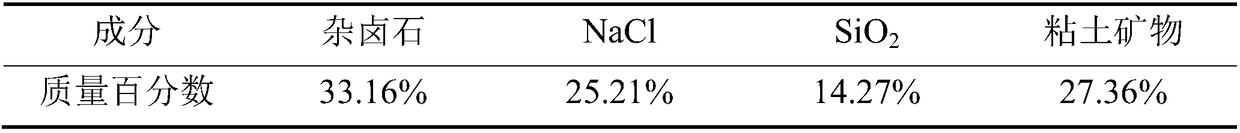

[0059] The main components of the low-grade polyhalite ore in this example are shown in Table 1.

[0060] Table 1 Main components of low-grade polyhalite ore

[0061]

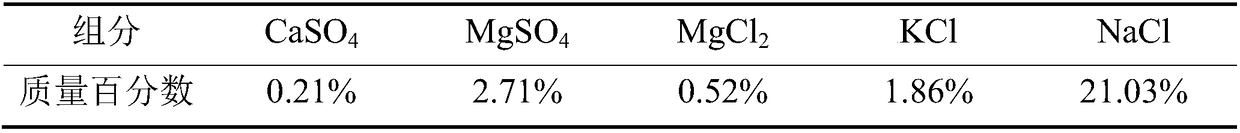

[0062] The main components of the saturated mother liquor used as the grinding medium in this embodiment are shown in Table 2.

[0063] The main components of the saturated mother liquor of table 2 grinding media

[0064]

[0065] Then, add adjuster and flocculant to the ore abrasive slurry, and mix uniformly to obtain flotation raw material.

[0066] In this ex...

Embodiment 2

[0090] In this embodiment, first, the low-grade polyhalite ore containing gangue minerals such as silicate, detrital salt, and halite is ground to -200 mesh (-0.074mm) and accounts for 75.33 wt%. For rod milling, sodium metaphosphate is added as a dispersant according to the addition amount of 90g / 1t polyhalite ore, the mass concentration of ore grinding is 50%, and the grinding medium is saturated mother liquor to obtain ore abrasive slurry.

[0091] The low-grade polyhalite ore of this embodiment is the same as that of Embodiment 1, as shown in Table 1.

[0092] The main components of the saturated mother liquor used as the grinding medium in this embodiment are shown in Table 6.

[0093] The main components of the saturated mother liquor of table 6 grinding media

[0094]

[0095] Then, add adjuster and flocculant to the ore abrasive slurry, and mix uniformly to obtain flotation raw material.

[0096] In this example, the adjusting agent is sodium hexadecylsulfonate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com