Method for separating and extracting natural theanine

A theanine, natural technology, applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems of limited life, high cost, cumbersome resin regeneration operation, etc., achieve less usage, good mechanical properties, and easy regeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

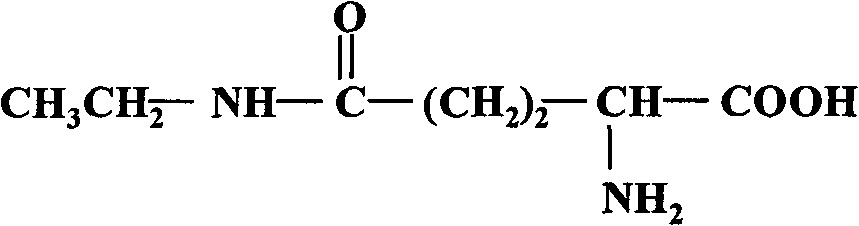

Image

Examples

Embodiment 1

[0025] Commercially available FAU zeolite powder (silicon-alumina ratio: 72) was processed into strips, activated in air at 550°C for four hours and cooled, placed in deionized water, degassed by ultrasonic, and filled into an adsorption column. Adsorption column height: 45cm, inner diameter: 3cm, zeolite adsorbent loading capacity 118g.

[0026] Weigh 1 g of theanine, prepare a 0.002 g / mL theanine solution, and adjust the pH value to 1-5 with hydrochloric acid-NaOH. At room temperature (25°C), pump 500mL of theanine aqueous solution to the adsorption column with a constant flow pump, adjust the flow rate to stabilize at 6.0mL / min, and analyze the theanine content of the effluent by sampling every 50ml. Elute with 0.2mol / L NaCl solution, collect the eluate, and analyze the content of theanine in the eluate. After 2-3 column volumes, the elution is basically complete, and the recovery rate is 80%.

Embodiment 2

[0028] Commercially available FAU zeolite powder with a silicon-to-aluminum ratio of 15 was processed into pellets with a particle size of 1.5 mm, calcined at 600°C for 3.5 hours, and treated with water vapor at 120°C for 2 hours. Placed in deionized water, degassed by ultrasonic, loaded into adsorption column. Adsorption column height: 45cm, inner diameter: 3cm, zeolite adsorbent loading capacity: 123g.

[0029] Weigh 5 grams of tea powder, prepare 0.01 g / mL tea, and filter to remove insoluble impurities. Adjust the flow rate to be stable at 8.0mL / min, pump 500mL of tea water solution to the adsorption column with a constant flow pump, and keep the temperature of the adsorption column at 60°C. After the tea solution is pumped out, immediately pump in deionized water until the effluent is colorless. Theanine was eluted with 1mol / L ammonia water, and the eluate was collected. Vacuum rotary evaporation to remove ammonia, concentrate to about 1 / 5 of the initial volume of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com