Extraction method of radix asteris polysaccharide and radix asteris polypeptide

An extraction method, the technology of Aster, is applied in the field of extraction of Aster polysaccharides and Aster polypeptides, which can solve the problems of good extraction effect, high yield, and incomplete utilization, and achieve the goals of streamlining production links, improving the utilization of whole fruits, and saving time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

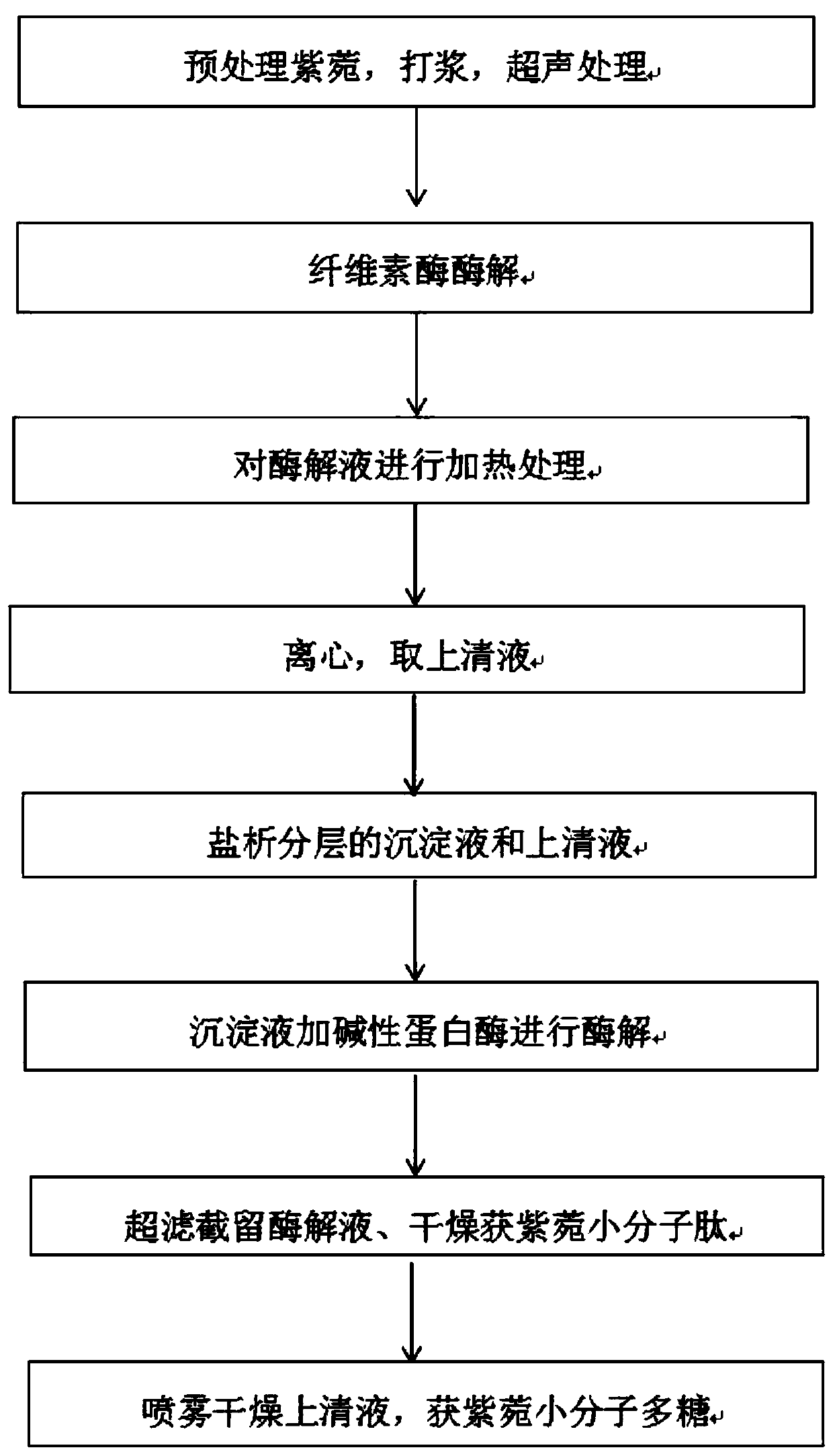

Method used

Image

Examples

Embodiment 1

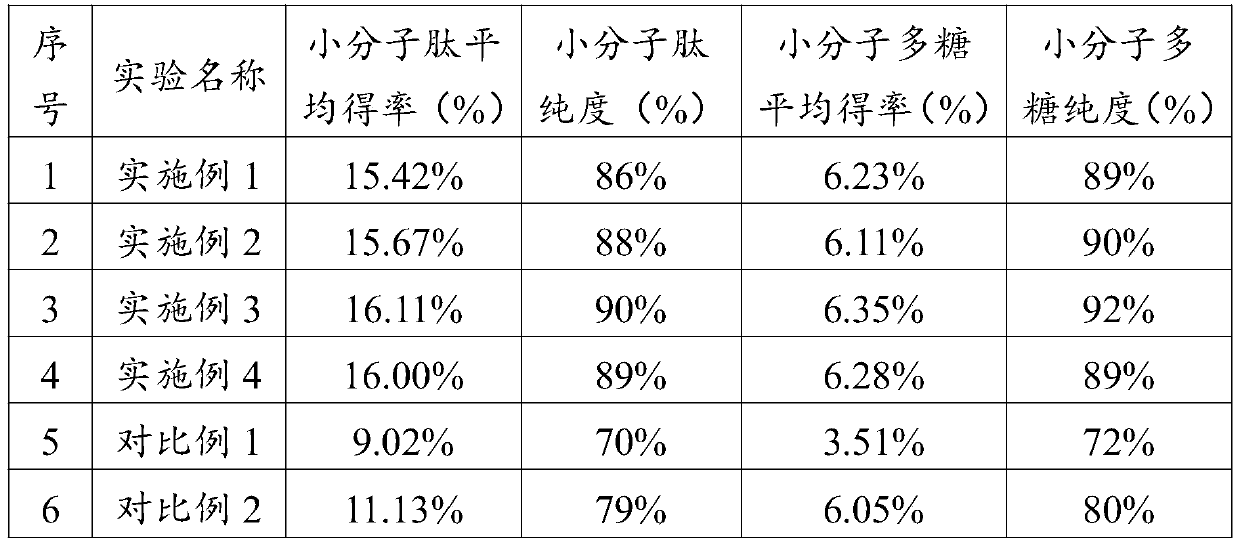

[0033] The preparation method for simultaneously extracting small molecular peptides and small molecular polysaccharides from asters comprises the following steps:

[0034] (1) Pretreatment of aster: After cleaning the aster with clean water, take 50 g of the aster, add water 5 times the mass of the aster, and perform beating treatment by mechanical method; and then ultrasonicate for 15 minutes under the condition of 20 kHz.

[0035] (2) Enzymolysis: add cellulase to the slurry, the mass ratio of cellulase to aster is 1:3000, adjust the pH to 5.5 at the same time, and enzymolysis time is 2 hours to obtain the first enzymolysis solution.

[0036] (3) Heat treatment: Pour the first enzymolysis solution into a container and heat for 30 minutes, set the temperature at 40°C, and cool for 12 hours after heating.

[0037] (4) Centrifugal treatment: put the heat-treated first enzymatic hydrolysis solution into a high-speed refrigerated centrifuge and centrifuge for 20 minutes with a c...

Embodiment 2

[0043] The preparation method for simultaneously extracting small molecular peptides and small molecular polysaccharides from Aster provided by this example includes the following steps:

[0044] (1) Pretreatment of aster: After cleaning the aster with clean water, take 50 g of the aster, add water 10 times the mass of the aster, and perform beating treatment by mechanical method; and then ultrasonicate for 35 minutes under the condition of 30 kHz.

[0045] (2) Enzymolysis: add cellulase to the slurry, the mass ratio of cellulase to aster is 1:4000, adjust the pH to 5.5 at the same time, and the enzymolysis time is 3 hours to obtain the first enzymolysis solution.

[0046] (3) Heat treatment: Pour the first enzymolysis solution into a container and heat for 40 minutes, set the temperature at 30°C, and cool for 12 hours after heating.

[0047] (4) Centrifugal treatment: put the heat-treated first enzymatic hydrolysis solution into a high-speed refrigerated centrifuge and centri...

Embodiment 3

[0053] The preparation method for simultaneously extracting small molecular peptides and small molecular polysaccharides from Aster provided by this example includes the following steps:

[0054] (1) Pretreatment of aster: After cleaning the aster with clean water, add water 15 times the mass of the aster, and perform beating treatment by mechanical method; and then ultrasonicate for 35 minutes under the condition of 20 kHz.

[0055] (2) Enzymolysis: add cellulase to the slurry, the mass ratio of cellulase to aster is 1:5000, adjust the pH to 6.5 at the same time, and the enzymolysis time is 3 hours to obtain the first enzymolysis solution.

[0056] (3) Heat treatment: Pour the first enzymolysis solution into a container and heat for 50 minutes, set the temperature at 40°C, and cool for 12 hours after heating.

[0057] (4) Centrifugal treatment: put the heat-treated first enzymatic hydrolysis solution into a high-speed refrigerated centrifuge and centrifuge for 25 minutes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com