Method for treating titanium-containing red mud

A red mud and treatment process technology, applied in the field of solid waste treatment, can solve the problems of low titanium content, increase the difficulty of recycling other elements such as iron, and low utilization value, reduce temperature and time, and achieve comprehensive recycling. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

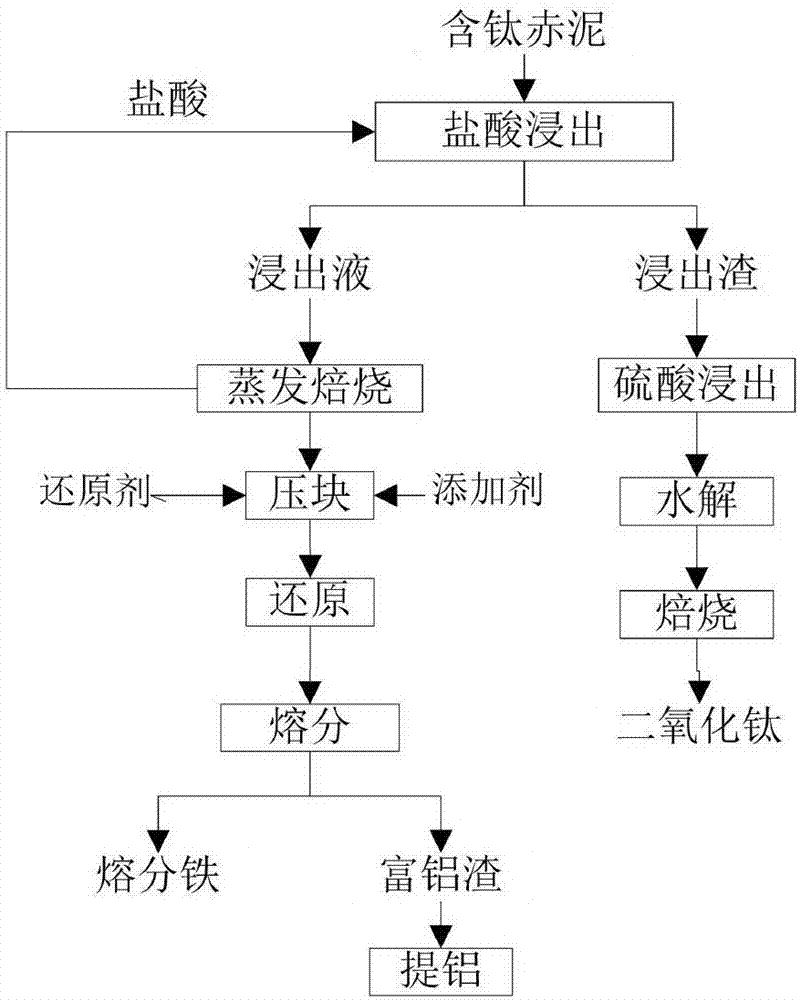

Image

Examples

Embodiment 1

[0038] The titanium-containing red mud with a titanium content of 8.25wt%, an iron content of 30.52wt%, and an aluminum content of 24.24wt% was leached with a hydrochloric acid solution, the concentration of the hydrochloric acid solution was 4mol / L, the leaching time was 60min, and the leaching temperature was 60°C to obtain a leaching residue and leachate.

[0039]Al 2 o 3 , Fe 2 o 3 etc., and recover the hydrochloric acid obtained by evaporation, and use it in the leaching process of titanium-containing red mud for recycling. Take 100 parts by weight of the mixture, add 6 parts by weight of additives and 25 parts by weight of reducing agent, mix evenly, and press into blocks to obtain green balls. After the green balls are dried, reduction and melting treatment are carried out, the reduction temperature is controlled at 1150°C, the reduction time is 25 minutes, the melting temperature is 1450°C, and the melting time is 40 minutes to obtain molten iron and aluminum-rich ...

Embodiment 2

[0042] The titanium-containing red mud with a titanium content of 15.26wt%, an iron content of 28.28wt%, and an aluminum content of 20.85wt% was leached with a hydrochloric acid solution, the concentration of the hydrochloric acid solution was 5mol / L, the leaching time was 60min, and the leaching temperature was 70°C to obtain a leaching residue and leachate.

[0043] Al 2 o 3 , Fe 2 o 3 etc., and recover the hydrochloric acid obtained by evaporation, and use it in the leaching process of titanium-containing red mud for recycling. Take 100 parts by weight of the mixture, add 6 parts by weight of additives and 25 parts by weight of reducing agent, mix evenly, and press into blocks to obtain green balls. After the green balls are dried, reduction and melting treatment are carried out, the reduction temperature is controlled at 1180°C, the reduction time is 30 minutes, the melting temperature is 1500°C, and the melting time is 50 minutes to obtain molten iron and aluminum-ric...

Embodiment 3

[0046] The titanium-containing red mud with a titanium content of 18.06wt%, an iron content of 27.86wt%, and an aluminum content of 18.15wt% was leached with a hydrochloric acid solution, the concentration of the hydrochloric acid solution was 6mol / L, the leaching time was 90min, and the leaching temperature was 70°C to obtain a leaching residue and leachate.

[0047] Al 2 o 3 , Fe 2 o 3 etc., and recover the hydrochloric acid obtained by evaporation, and use it in the leaching process of titanium-containing red mud for recycling. Take 100 parts by weight of the mixture, add 6 parts by weight of additives and 25 parts by weight of reducing agent, mix evenly, and press into blocks to obtain green balls. After the green balls are dried, reduction and melting treatment are carried out, the reduction temperature is controlled at 1200°C, the reduction time is 30 minutes, the melting temperature is 1500°C, and the melting time is 50 minutes to obtain molten iron and aluminum-ric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com