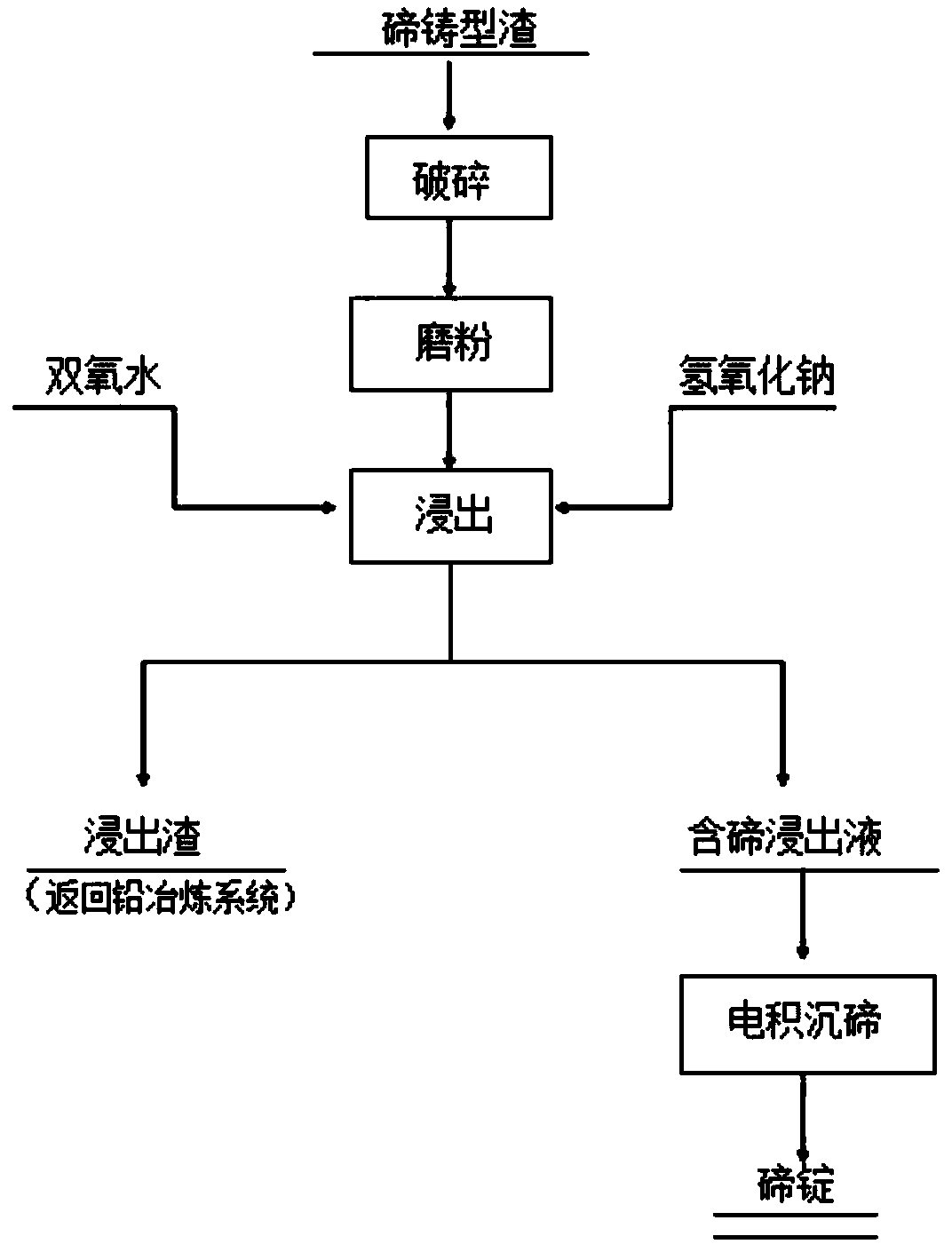

Method for recycling tellurium from tellurium mould residue

A casting mold and powder technology, which is applied in the field of non-ferrous metal recycling, can solve the problems of high impurities in tellurium-containing leaching solution, high consumption of chemical agents, unqualified tellurium products, etc., and achieve the effect of less impurities, low equipment requirements, and small equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 2000g of tellurium casting slag (Te 73.18%, Pb 0.64%, Ag 0.055%) is crushed, ground into a tellurium casting slag powder with a particle size of 120 mesh, the tellurium casting slag powder is placed in a reaction tank, and then poured into the reaction tank Add 6L of sodium hydroxide solution with a concentration of 160g / L and mix evenly, add 4L of hydrogen peroxide with a mass percentage of 30% at a rate of 10ml / min at 85°C, and keep stirring to carry out the oxidation leaching reaction. The stirring speed is 500r / min, after 2 hours of reaction, liquid-solid separation is carried out to obtain tellurium-containing leaching solution and leaching slag. After washing and sampling, the leaching slag is returned to the lead smelting system to recover Ag and Pb valuable metals; the tellurium-containing leaching solution is directly returned to the electrowinning process to recover metal tellurium. Sampling analysis shows that the recovery rate of tellurium in tellurium castin...

Embodiment 2

[0037]2000g of tellurium casting slag (Te75.00%; Pb0.81%; Ag0.049%) is crushed, ground into tellurium casting slag powder with a particle size of 100 mesh, the tellurium casting slag powder is placed in a reaction tank, and then Add 8L of sodium hydroxide solution with a concentration of 150g / L to the reaction tank and mix evenly, add 5L of hydrogen peroxide with a mass percentage of 30% at a rate of 10ml / min at 80°C, and keep stirring to carry out the oxidation leaching reaction. The speed is 600r / min. After 3 hours of reaction, liquid-solid separation is carried out to obtain tellurium-containing leaching solution and leaching slag. After washing and sampling, the leaching slag is returned to the lead smelting system to recover Ag and Pb valuable metals; the tellurium-containing leaching solution is directly returned to the electrowinning process to recover metals. tellurium. Sampling analysis showed that the recovery rate of tellurium in tellurium casting slag was as high a...

Embodiment 3

[0039] 2000g of tellurium casting slag (Te70.00%; Pb0.89%; Ag0.076%) is crushed, ground into tellurium casting slag powder with a particle size of 120 meshes, the tellurium casting slag powder is placed in a reaction tank, and then Add 10L of sodium hydroxide solution with a concentration of 160g / L into the reaction tank and mix evenly, add 5L of hydrogen peroxide with a mass percentage of 30% at a rate of 10ml / min at 75°C, and keep stirring to carry out the oxidation leaching reaction. The speed is 800r / min. After 4 hours of reaction, liquid-solid separation is carried out to obtain tellurium-containing leaching solution and leaching slag. After washing and sampling, the leaching slag is returned to the lead smelting system to recover Ag and Pb valuable metals; the tellurium-containing leaching solution is directly returned to the electrowinning process to recover metals tellurium. Sampling and analysis show that the recovery rate of tellurium in tellurium casting slag is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com