Middle-widthed band automatic bundling method and middle-widthed band automatic bundling machine

A strapping machine, automatic technology, applied in the direction of bundling materials, packaging, etc., can solve the problems of not tight bundling, not tight straps, complex problems, etc., to increase the radius of curvature, ensure convenience and safety, and reduce plastic deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

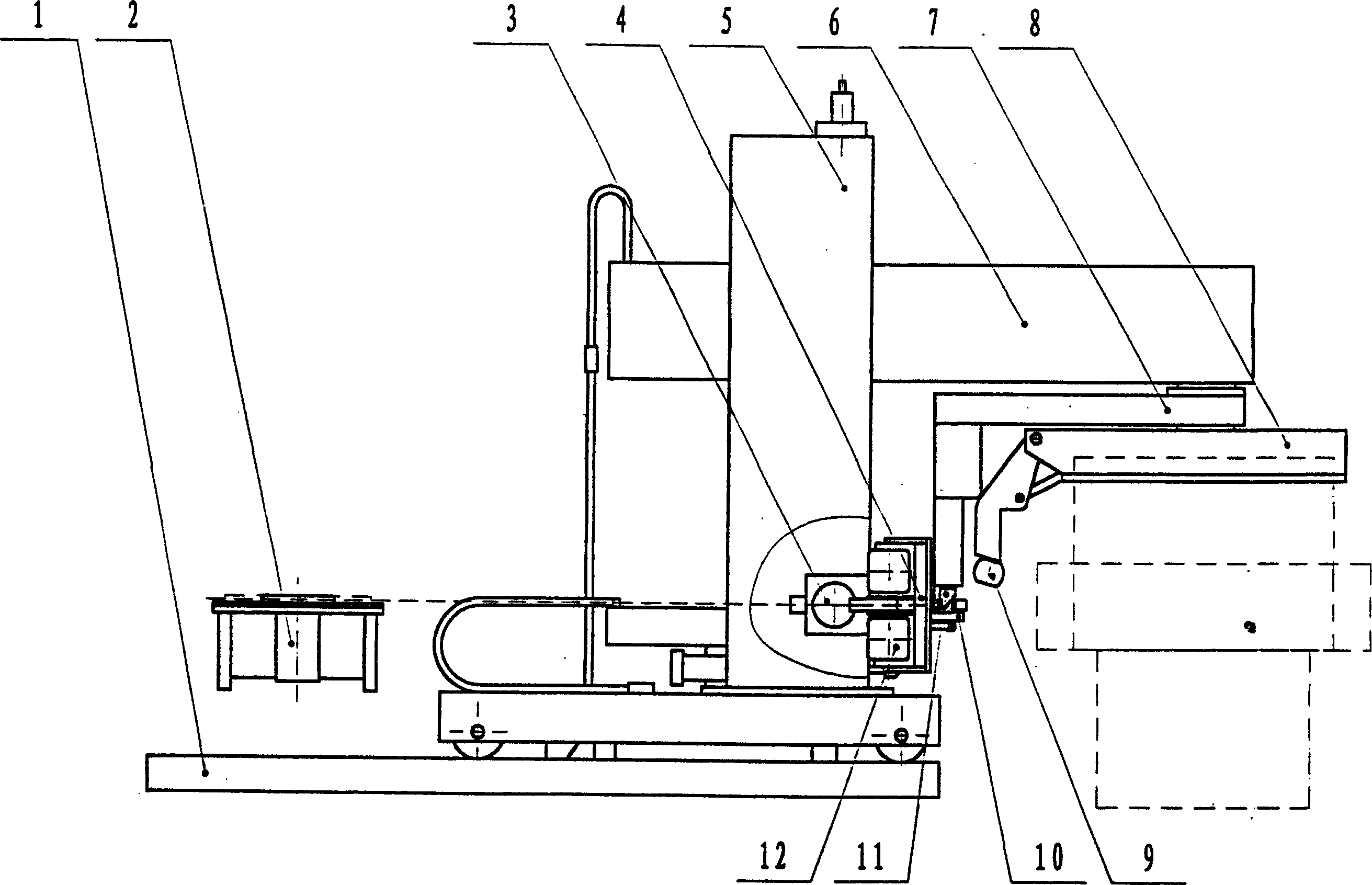

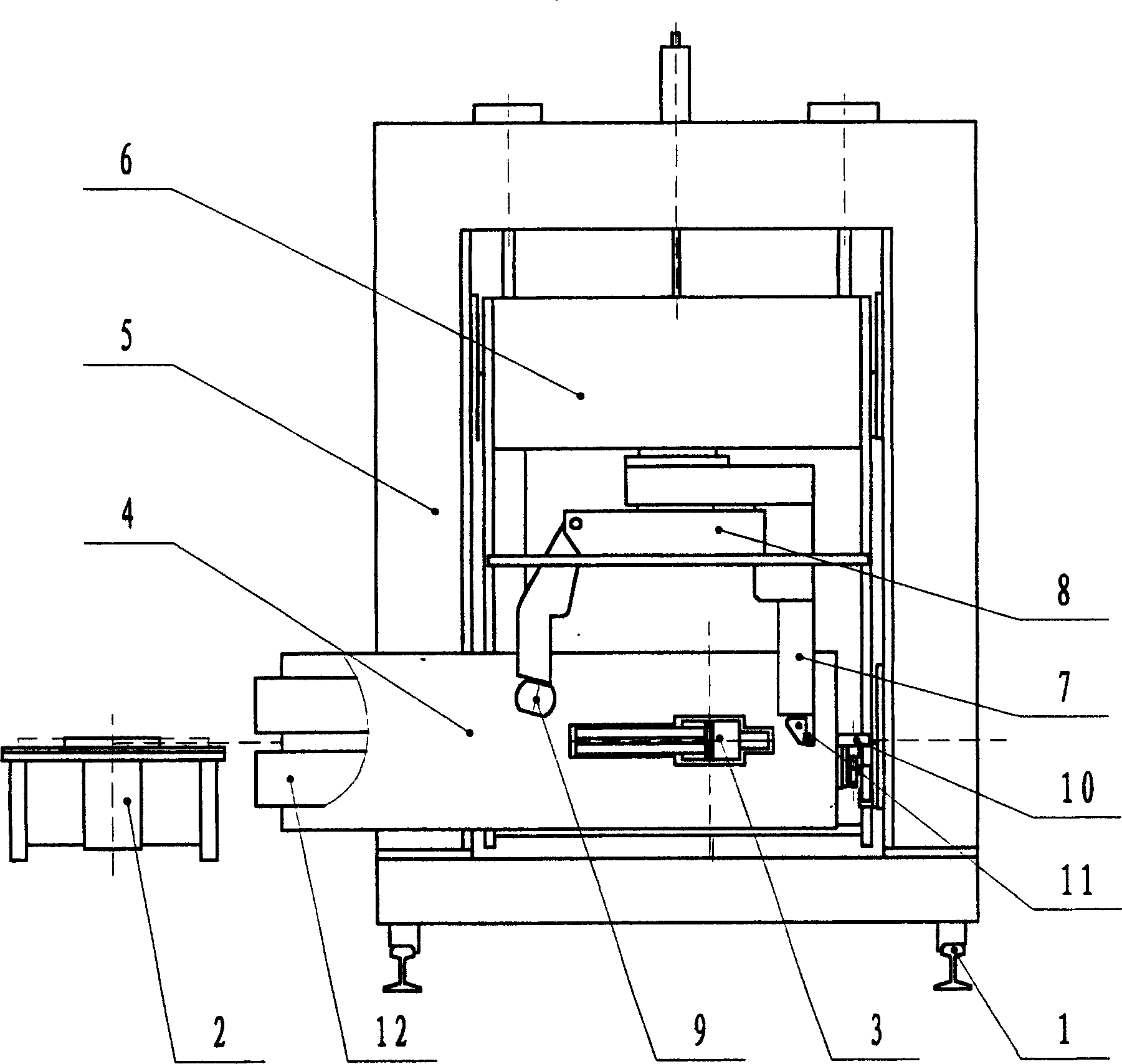

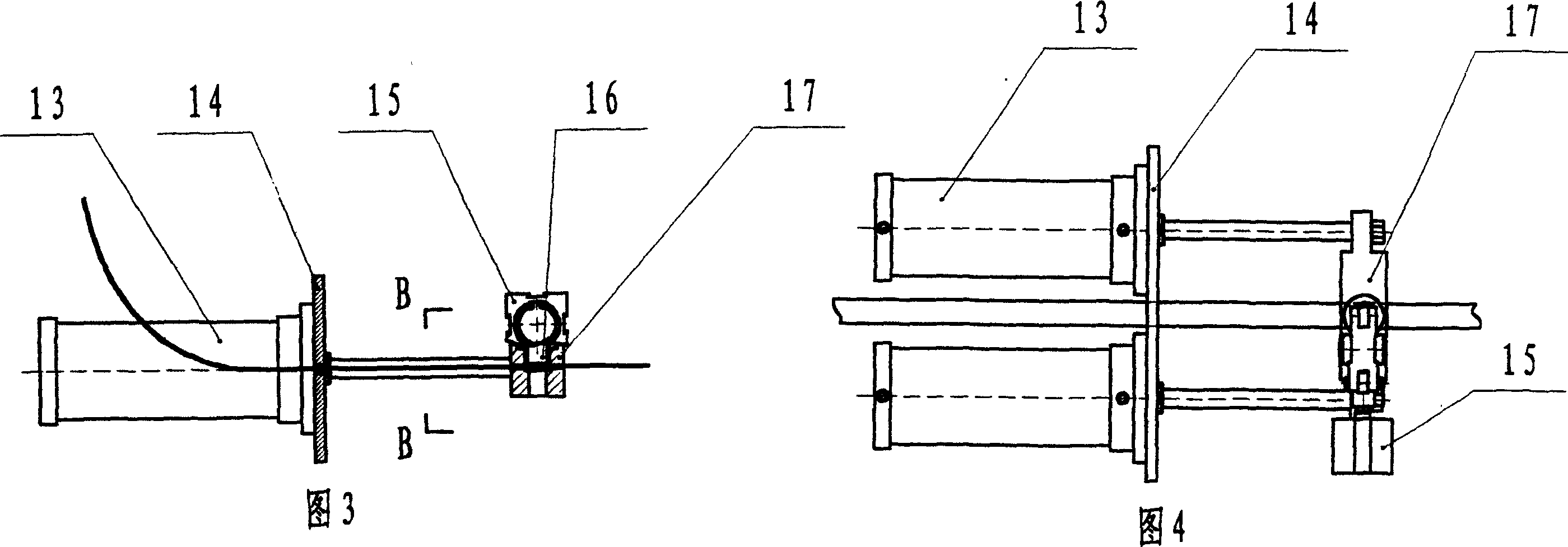

[0025] The broadband automatic bundling method in the present invention includes the process of automatic belt feeding, belt pressing, tensioning, sealing, and belt cutting, wherein the belt feeding process is divided into the belt feeding process of the belt feeding mechanism and the belt delivery process around the bundled steel coils. The process of strapping, wherein the process of conveying the strap around the bundled steel coil is completed in the following manner: use the grabbing pliers to grab the strap head sent out by the feeding and pulling mechanism, and use the strap feeding arm to make the strap surround the bundled steel coil in space. The bundled steel coil rotates once to achieve the purpose of belt feeding.

[0026] In order to recover the tail of the lifted steel coil, the present invention increases the process of pressing the bound steel coil before the belt feeding arm rotates around the bound steel coil, that is, the pressing arm moves along the bound s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com