Modified poly(lactic acid) masterbatch prepared from poly(lactic acid) residual material or waste material and application thereof

A technology of polylactic acid and residual materials, which is applied in the field of polymer compounds, can solve problems such as difficult recycling, achieve good uniformity, excellent mechanical properties, and reduce dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The formula (parts by weight) of the modified polylactic acid masterbatch of the present invention is as follows:

[0030] 1. 75.0 parts of flaky polylactic acid residues or waste materials, said polylactic acid residues or waste materials are poly-L-lactic acid, polyDL-lactic acid or a copolymer blend of the former two, and its number-average molecular weight is 2- 50000.

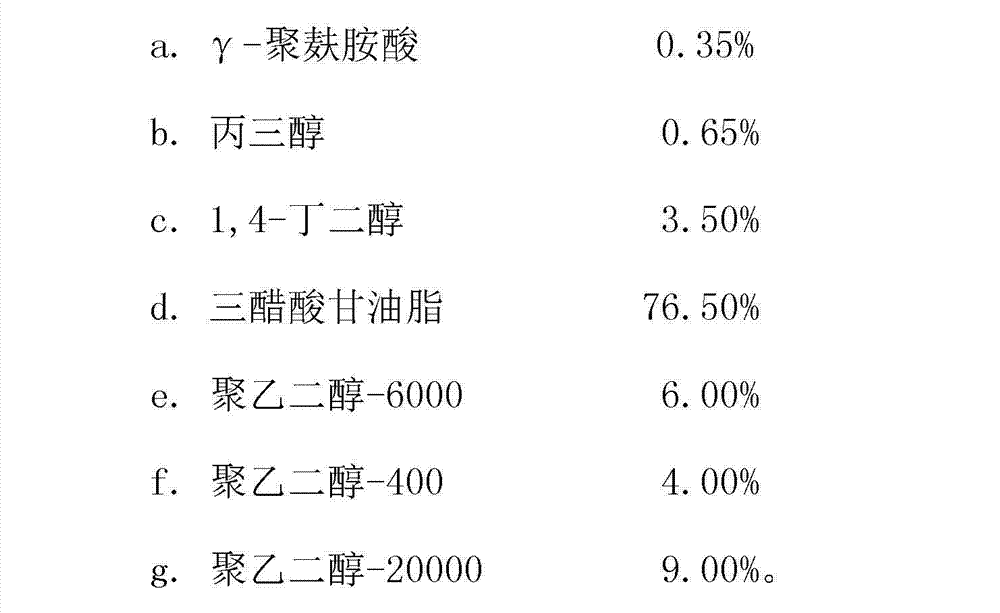

[0031] 2. 18.0 parts of toughening modifier, each component of described toughening modifier is calculated as by weight percentage:

[0032]

[0033] 3. 2.0 parts of plasticizer, each component of said plasticizer is calculated by weight percentage:

[0034] a. Acetyl tri-n-butyl citrate 40.00%

[0035] b. Triethyl citrate 20.00%

[0036] c. Dibutyl sebacate 40.00%

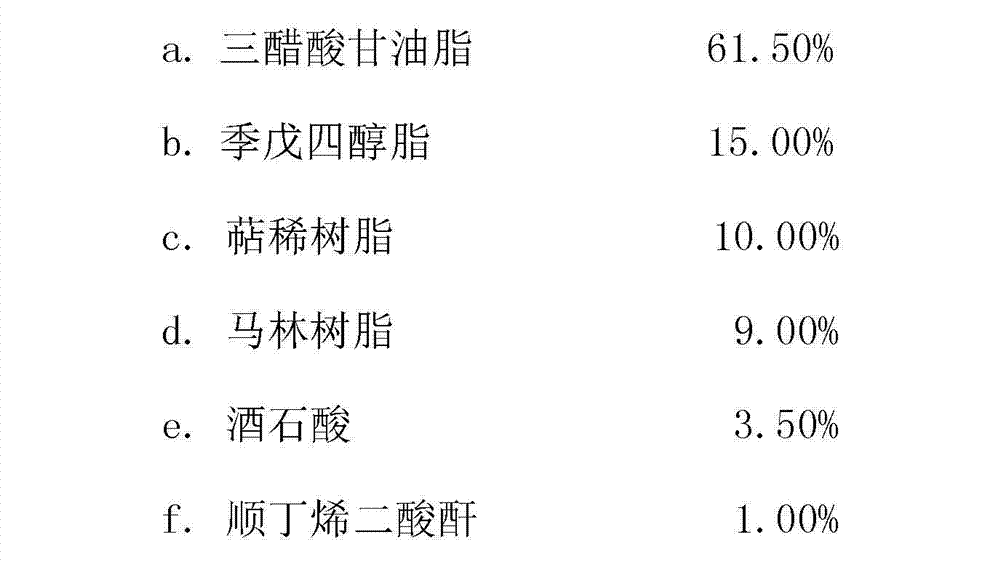

[0037] 4. 3.30 parts of heat-resistant modifier, each component of the heat-resistant modifier is calculated by weight percentage:

[0038]

[0039] 5. 1.0 parts of lubricant, each component of the lubricant is calculated by ...

Embodiment 2

[0048] The formula (parts by weight) of the modified polylactic acid masterbatch of the present invention is as follows:

[0049] 75.0 parts of flaky polylactic acid residue or waste material, 15.3 parts of toughening modifier, 3.5 parts of plasticizer, 4.5 parts of heat-resistant modifier, 1.0 part of lubricant, 0.3 part of nucleating agent, 0.25 part of antioxidant, 0.15 parts of anti-ultraviolet agent, the specific components and mass percentages of the aforementioned materials are the same as in Example 1.

[0050] The performance data of the film prepared by using the above-mentioned modified polylactic acid masterbatch are as follows: tensile strength (MPa)-longitudinal (MD), 32.3MPa; tensile strength (MPa)-transverse (TD), 28.2MPa; elongation at break Elongation (%) - longitudinal direction (MD), 305%; elongation at break (%) - transverse direction (TD), 262%, Vicat softening temperature (°C): 87.

Embodiment 3

[0052] The formula (parts by weight) of the modified polylactic acid masterbatch of the present invention is as follows:

[0053] 75.0 parts of flaky polylactic acid residue or waste material, 13.3 parts of toughening modifier, 5.0 parts of plasticizer, 5.0 parts of heat-resistant modifier, 1.0 part of lubricant, 0.3 part of nucleating agent, 0.25 part of antioxidant, 0.15 parts of anti-ultraviolet agent, the specific components and mass percentages of the aforementioned materials are the same as in Example 1.

[0054] The performance data of the film prepared by using the above-mentioned modified polylactic acid masterbatch are as follows: tensile strength (MPa)-longitudinal (MD), 30.8MPa; tensile strength (MPa)-transverse (TD), 25.9MPa; elongation at break Elongation (%) - longitudinal direction (MD), 282%; elongation at break (%) - transverse direction (TD), 249%, Vicat softening temperature (°C): 88.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com