Recovery device for recovery of heavy metal in scraps of neodymium iron boron by utilizing saponification and extraction

A technology for recycling NdFeB and recycling devices, which is applied in the field of metallurgy and can solve problems such as damaging the environment, wasting resources, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described in conjunction with the following examples.

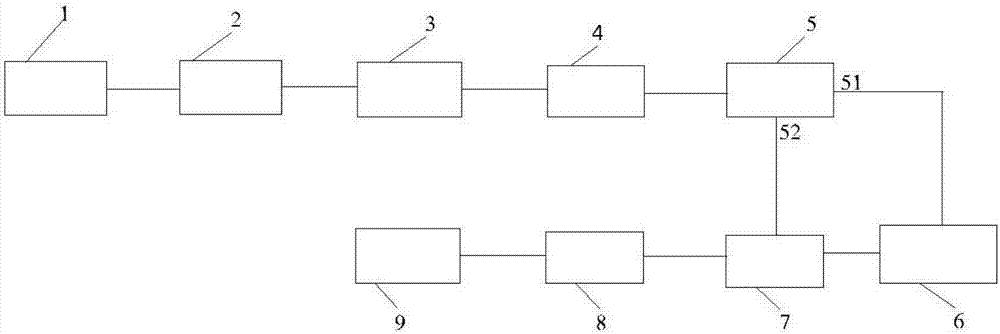

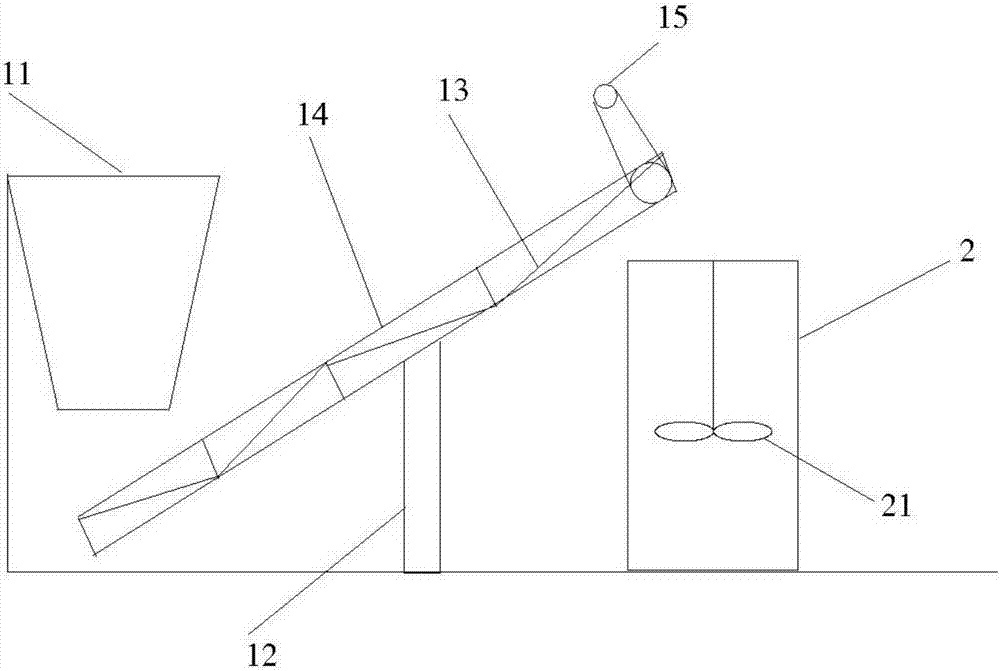

[0028] Such as figure 1 and figure 2 As shown, the feeding system 1 includes a feed hopper 11, a support 12, a conveyor frame 13, a conveyor belt 14 and a motor 15; the conveyor frame 13 is fixed on the frame 12, the conveyor frame 13 is connected to the conveyor belt 14, and the motor 15 is fixed on Conveyor frame 13, motor 15 drives the conveyor belt 14 to rotate; the upper end of the conveyor frame 13 is connected to the input end of the grinding device 2, and the lower end is located below the funnel hole of the feeding funnel 11. The specific feeding funnel 11 adopts a vibrating feeding funnel, neodymium iron The boron waste is put into the feeding hopper 11 and vibrated, and then the motor 15 is used to drive the conveyor belt 14 to rotate to transport the NdFeB waste to the grinding device 2 for grinding. Feeding through the automatic feeding system 1 can improve production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com