Production method of deinked pulp and environmentally-friendly white cardboard made of deinked pulp

A production method and technology for deinking pulp, applied in papermaking, pulp bleaching, textiles and papermaking, etc., can solve problems such as unfavorable environmental protection, inability to meet demand, intensified market demand, etc., to improve covering performance, increase recycling, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

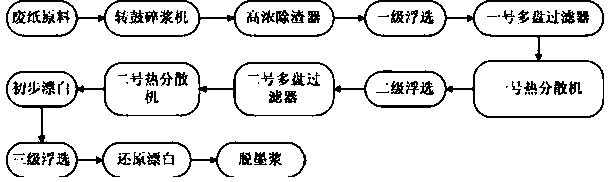

[0051] A method for producing deinked pulp includes the following steps:

[0052] (1) Put the waste paper raw materials into a drum pulper and add water at a temperature of 60°C to crush to obtain a slurry; among them, the drum pulper has a crushing temperature of 50°C during the crushing process, and the crushing pH is 8.5; Waste paper raw materials are composed of US waste 37#, daily waste 3# and office waste paper. The components of waste paper raw materials are measured in parts by weight as follows:

[0053] US waste 37# 38 copies

[0054] Daily waste 3# 40 copies

[0055] Office waste paper 20 copies

[0056] (2) After removing the slag, pass the slurry into the first-level flotation tank, the first multi-disc filter, the first thermal dispersion machine, the second-level flotation tank, the second multi-disc filter and the second disperser in sequence The impurity removal process is carried out to remove organic impurities in the slurry. The energy consumption of the No. 1 ...

Embodiment 2

[0067] A method for producing deinked pulp includes the following steps:

[0068] (2) Put the waste paper raw materials into a drum pulper and add water with a temperature of 63℃ to crush to obtain a slurry; among them, during the crushing process, the drum pulper’s disintegration temperature is 53℃, and the disintegration pH is 8.8; Waste paper raw materials are composed of US waste 37#, daily waste 3# and office waste paper. The components of waste paper raw materials are measured in parts by weight as follows:

[0069] US waste 37# 40 copies

[0070] Daily waste 3# 45 copies

[0071] Office waste paper 25 copies

[0072] (2) After removing the slag, pass the slurry into the first-level flotation tank, the first multi-disc filter, the first thermal dispersion machine, the second-level flotation tank, the second multi-disc filter and the second disperser in sequence The impurity removal process is carried out to remove organic impurities in the slurry. The energy consumption of t...

Embodiment 3

[0083] A method for producing deinked pulp includes the following steps:

[0084] (3) Put the waste paper raw materials into a drum pulper and add water at a temperature of 66℃ to crush to obtain a slurry; among them, during the crushing process, the drum pulper has a disintegration temperature of 56℃ and a disintegration pH of 9.2; Waste paper raw materials are composed of US waste 37#, daily waste 3# and office waste paper. The components of waste paper raw materials are measured in parts by weight as follows:

[0085] US waste 37# 40 copies

[0086] Daily waste 3# 43 copies

[0087] Office waste paper 22 copies

[0088] (2) After removing the slag, pass the slurry into the first-level flotation tank, the first multi-disc filter, the first thermal dispersion machine, the second-level flotation tank, the second multi-disc filter and the second disperser in sequence The impurity removal process is carried out to remove organic impurities in the slurry. The energy consumption of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy consumption | aaaaa | aaaaa |

| Energy consumption | aaaaa | aaaaa |

| Energy consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com