Method for recovering tellurium from high-tellurium residues

A technology of slag and tellurium slag, applied in the field of non-ferrous metal hydrometallurgy, can solve the problems of difficult oxidation of tellurium metal, unqualified tellurium products, incomplete removal of impurities, etc., and achieve low production cost, no environmental pollution, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

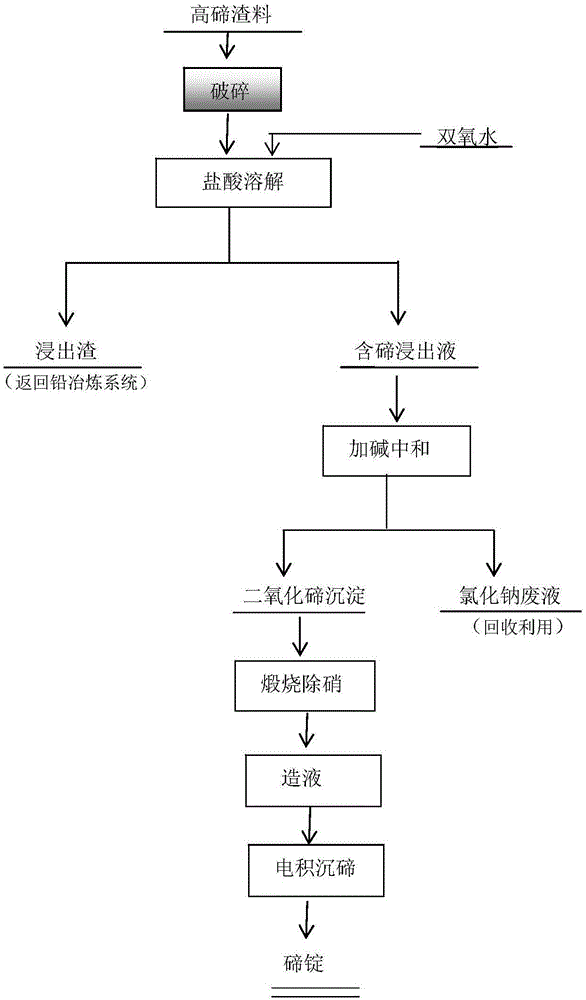

[0032] The flow chart of the method for recovering tellurium from high tellurium slag material in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0033] Crush 5000g of high tellurium slag material (Te 73.18%, 3659g; Pb 0.64%, 32g; Ag 0.055%, 2.75g) to a particle size ≤ 10mm, slowly add 16L of hydrochloric acid and hydrogen peroxide mixed solution prepared in advance into the reaction tank and keep stirring , carry out oxidative leaching; wherein, in the oxidative leaching stage, hydrochloric acid is concentrated hydrochloric acid for industrial use, hydrogen peroxide is industrial hydrogen peroxide with a content of 20% to 40%, the mass ratio of hydrochloric acid to high tellurium slag material is 1.1:1, hydrogen peroxide and high tellurium slag The mass ratio of the material is 1.5:1; the temperature is controlled at 70-80°C, and the liquid-solid separation is carried out after the high-tellurium slag material is completely dissolved to o...

Embodiment 2

[0035] The flow chart of the method for recovering tellurium from high tellurium slag material in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0036]5000g of high tellurium slag material (Te 71.08%, 3554g; Pb 0.79%, 39.5g; Ag 0.062%, 3.1g) was crushed to a particle size ≤ 10mm, and 12L of hydrochloric acid and hydrogen peroxide mixed solution prepared in advance was slowly added to the reaction tank and continuously Stir and carry out oxidation leaching; wherein, in the oxidation leaching stage, hydrochloric acid is industrial concentrated hydrochloric acid, hydrogen peroxide is industrial hydrogen peroxide with a content of 20-40%, the mass ratio of hydrochloric acid to high tellurium slag material is 2.5:1, hydrogen peroxide and high tellurium slag The mass ratio of the slag is 3:1; the temperature is controlled at 70-80°C, and the liquid-solid separation is carried out after the high-tellurium slag is completely dissolved to obtain t...

Embodiment 3

[0038] The flow chart of the method for recovering tellurium from high tellurium slag material in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0039] Break 5000g of high tellurium slag material (Te 70.01%, 3501g; Pb 0.85%, 42.5g; Ag 0.071%, 3.55g) to particle size ≤ 10mm, slowly add 14L of hydrochloric acid and hydrogen peroxide mixed solution prepared in advance into the reaction tank and continuously Stir and carry out oxidation leaching; wherein, in the oxidation leaching stage, hydrochloric acid is concentrated hydrochloric acid for industrial use, hydrogen peroxide is industrial hydrogen peroxide with a content of 20% to 40%, the mass ratio of hydrochloric acid to high tellurium slag material is 2.0:1, hydrogen peroxide and high tellurium slag The mass ratio of the slag is 2.5:1; the temperature is controlled at 50-70°C, and the liquid-solid separation is carried out after the high-tellurium slag is completely dissolved to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com