Recovery method of waste lithium battery

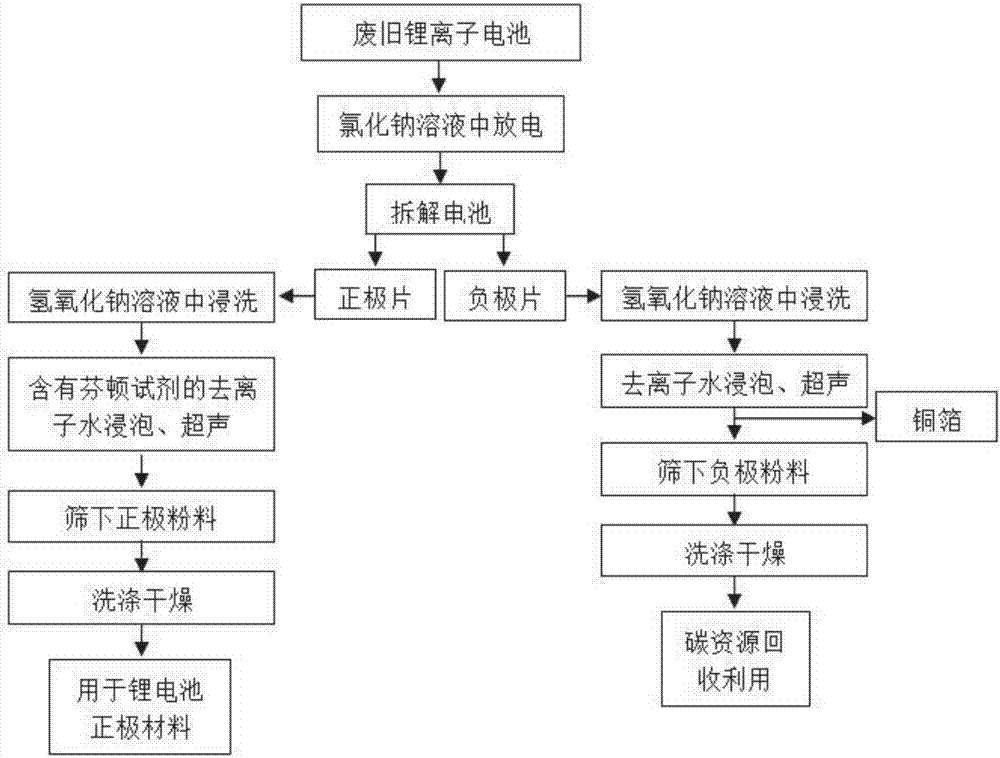

A waste lithium battery and recovery method technology, which is applied in the field of separation and recovery of current collectors and active materials in waste lithium batteries, can solve the problems of complex process, inability to recycle negative electrode materials, sewage, etc., and achieve short process flow and high degree of recycling High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) The lithium cobalt oxide lithium-ion batteries collected are waste batteries of Huawei mobile phones, and these batteries are first placed in a sodium chloride solution for discharge treatment;

[0081] (2) Under the atmosphere full of nitrogen, the battery is cut open, the positive and negative active materials are taken out, respectively placed in 1% sodium hydroxide solution for 25 minutes, and rinsed with deionized water; the electrolyte components must be removed positive and negative electrodes.

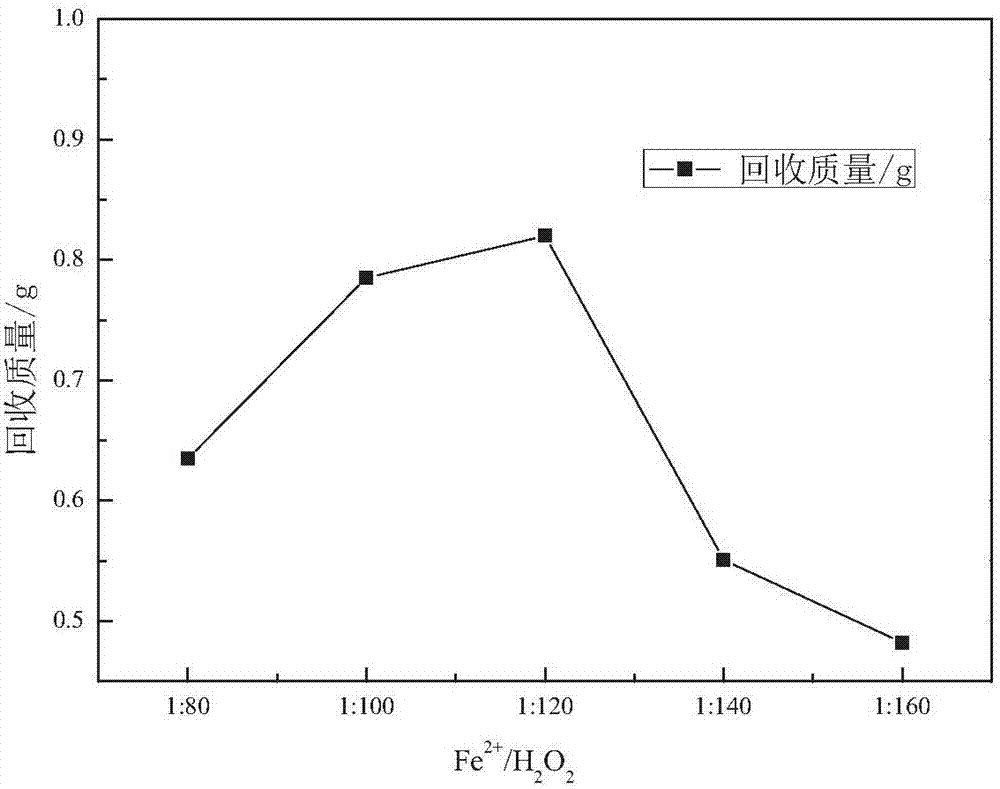

[0082] (3) process the positive electrode sheet (1g) obtained in step (2), and then soak it in an aqueous solution containing Fenton's reagent (Fe 2+ / H 2 o 2 molar ratio of 1:120) in deionized water (Fe 2+ The molar concentration is 0.1mol / L); Then transfer to the reactor with ultrasonic generator, the temperature is adjusted to 65 degrees, and the ultrasonic sound intensity is 40W / cm 2 Shock 1-2h;

[0083] Sieve the positive electrode sheet solution after the ...

Embodiment 2

[0086] Compared with Example 1, the difference is only that the Fe of Fenton's reagent 2+ / H 2 o 2 The mol ratio is 1: 80, and other processing methods are identical with embodiment 1. The recovered mass of the cathode material was 0.635 g.

Embodiment 3

[0088] Compared with Example 1, the difference is only that the Fe of Fenton's reagent 2+ / H 2 o 2 The mol ratio is 1: 100, and other processing methods are identical with embodiment 1. The recovered mass of the cathode material was 0.785 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com