Horizontal magnetic bar filter

A filter and magnetic rod technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increased production cost, reduced flow capacity, increased liquid resistance, etc., to promote recycling and improve service life , the effect of protecting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

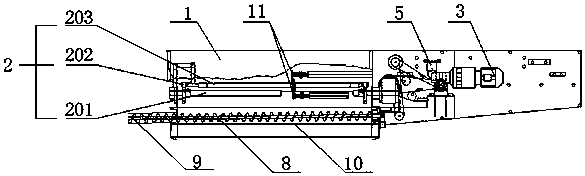

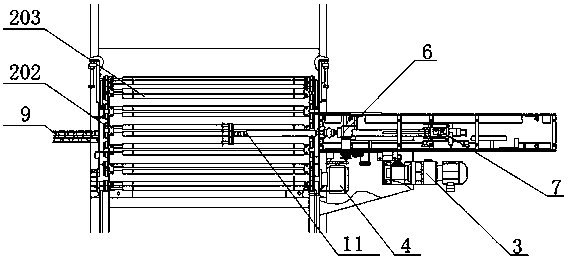

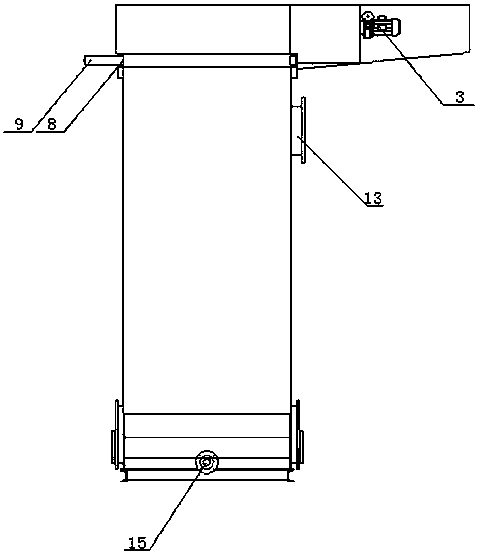

[0020] refer to Figure 1 to Figure 4 A horizontal magnetic rod filter of the present invention will be further described.

[0021] A horizontal magnetic rod filter, comprising a filter main body 1, the filter main body 1 is provided with a transmission device 2, the transmission device 2 includes a transmission shaft 201, a chain 202, a magnetic rod 203, the filter main body The outer side of 1 is provided with frequency conversion speed regulation reducer 3, chain transmission reduction box 4, spring type chain tensioner 5, sewage transmission transmission reduction box 6 and magnetic rod scraping and sewage opening and closing action mechanism 7, and the sewage transmission transmission reduction box 6 is connected There is a screw rod 8, the outer end of the screw rod 8 is provided with an iron powder sludge outlet 9, a groove 10 is provided below the movement track of the magnetic rod scraping rake 11, and the opening and closing action mechanism of the magnetic rod scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com