Thin-ore-body shallow hole shrinkage method without sill pillar

A shallow-hole ore retention method and a technology without bottom pillars is applied in the field of mine mining technology, which can solve the problems of investing a lot of manpower, material resources and time, and achieve the effects of improving the recovery rate, reducing labor intensity and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

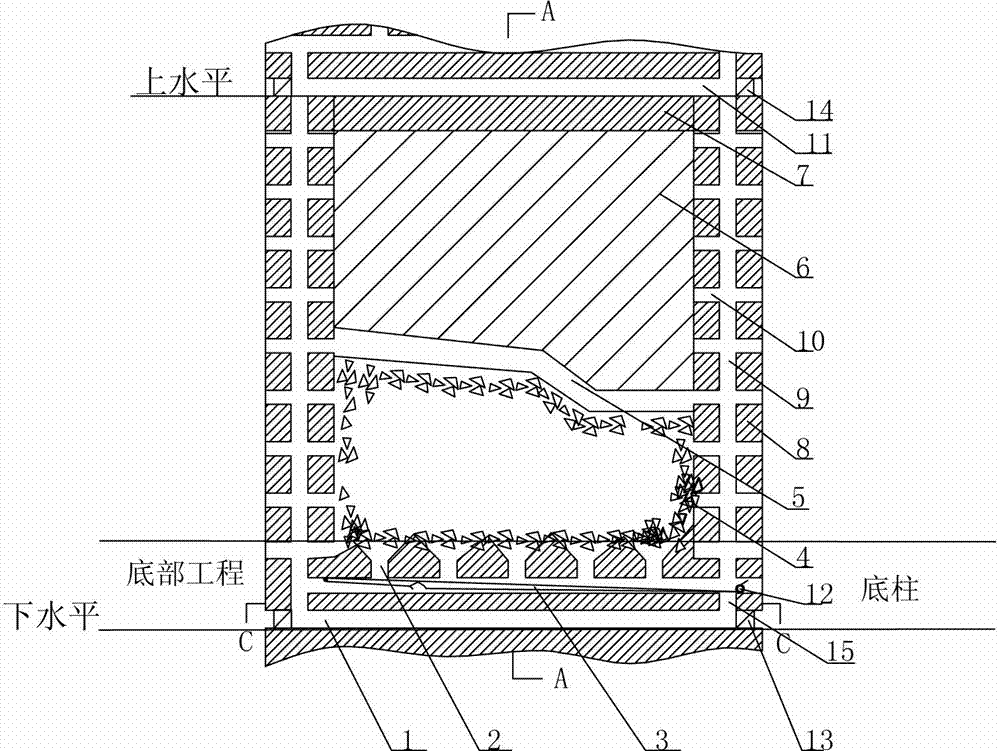

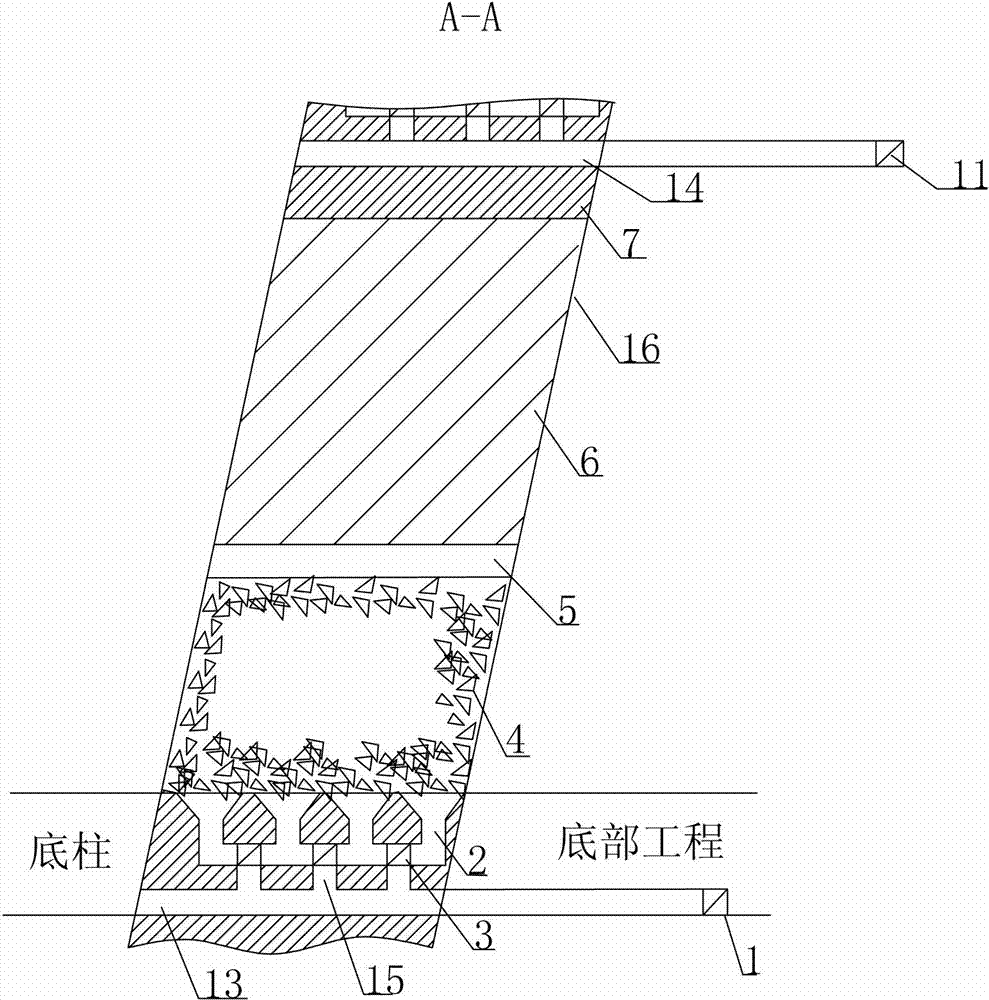

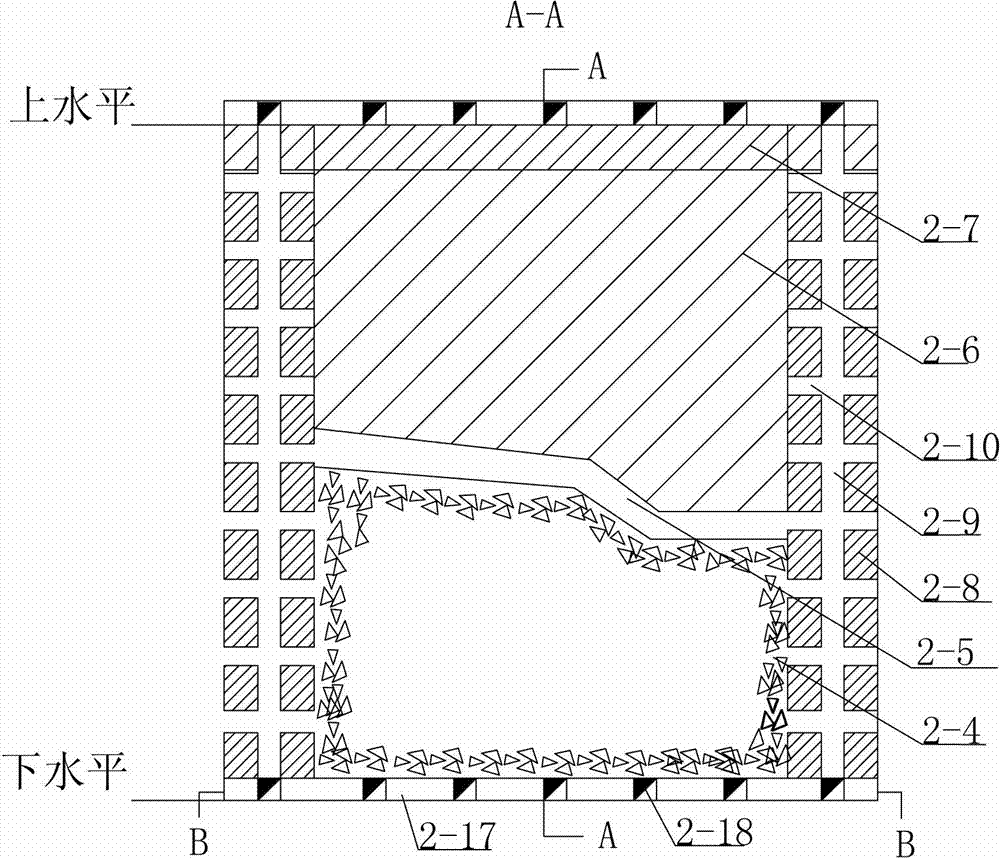

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0036] Including mining quasi-engineering, cutting engineering, mining engineering and mining engineering, it is characterized in that: comprising the following steps:

[0037] The said approval project:

[0038] Such as image 3 , Figure 4 , Figure 5 , at the lower level, at the lower level of a mining house, after the completion of the stage transportation roadway, excavate the forklift out of the ore roadway 2-18 to the ore body every 5-8m, and at the same time from the stage transportation roadway 2-1 to the left and right sides of the mine house Drill into the connecting road 2-19 of the patio at the part of the inter-column 2-8. After excavating into the ore body, excavate the patio 2-9 upwards. Excavate the connecting road 2-10 into the stope from the left and right, excavate 4-5m horizontally at the connecting road 2-10 ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com