Portal machining center combination for large part machining

A technology for processing centers and large parts, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of incomplete cleaning of iron filings, affecting processing efficiency, inconvenient disassembly and assembly, etc., and achieves easy processing and production , high chip removal efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

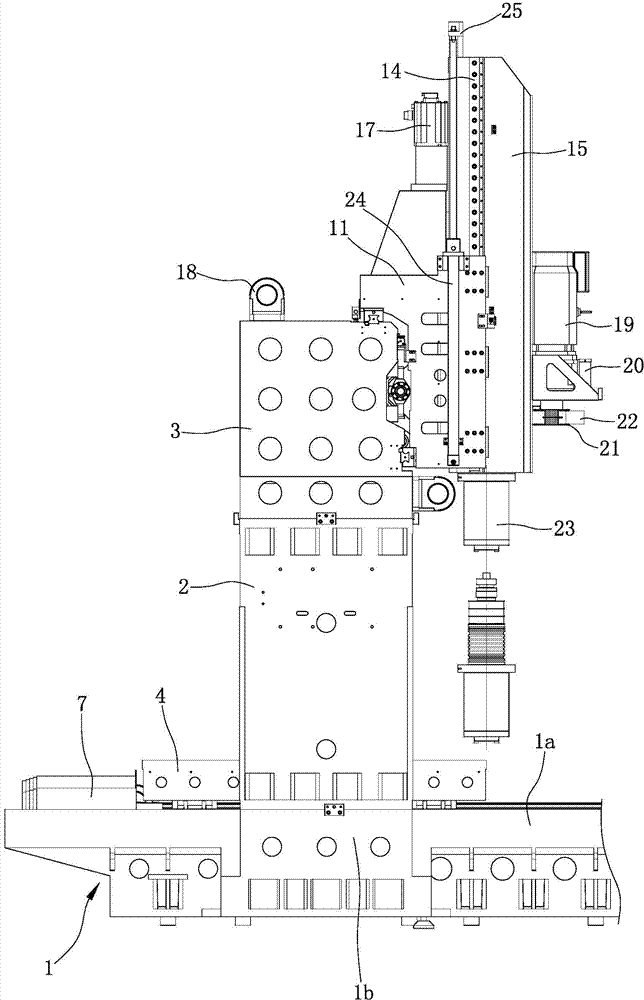

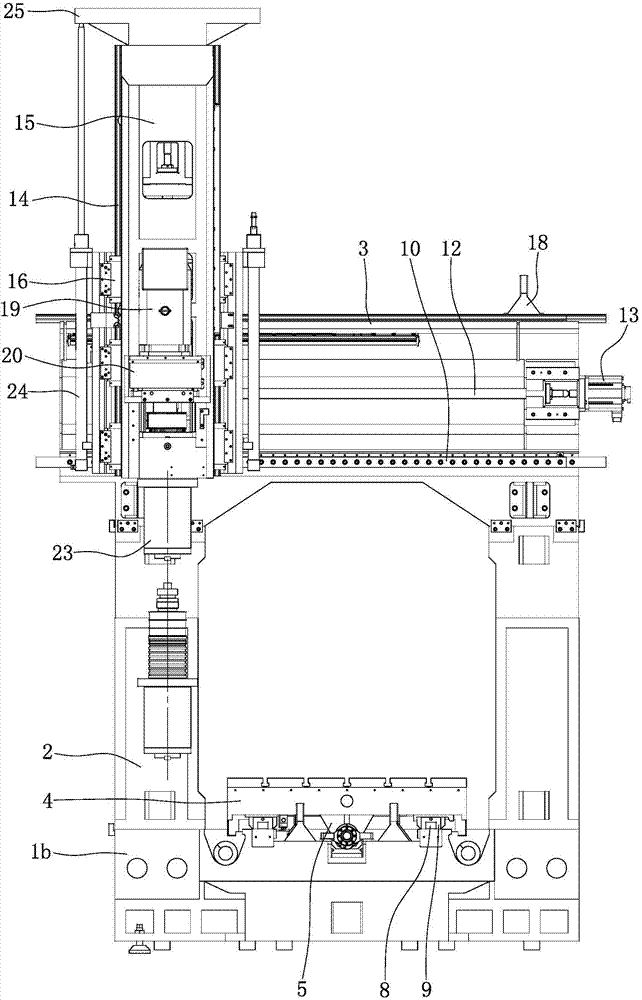

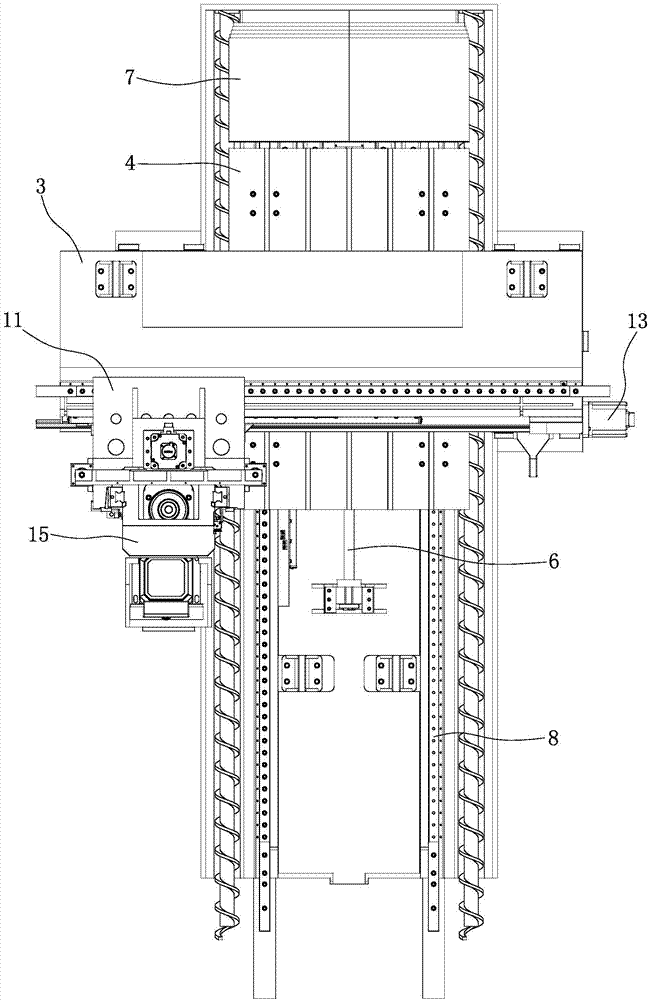

[0030] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, a rectangular support platform 1a is integrally formed on the top of the base 1, and the left and right sides of the top of the support platform 1a are symmetrically provided with chip removal grooves 1c, and the chip removal grooves 1c extend along the front and rear directions. It is "V" shape, and the front end of the chip removal groove 1c penetrates to the front end surface of the support table 1a. A spiral chip conveyor 26 is installed in each chip flute 1c. The spiral chip conveyor 26 is a prior art, and its structure will not be repeated here. During the operation of the screw chip conveyor 26, the iron chips in the chip removal groove 1c can be conveyed from the back to the front.

[0031] Such as Figure 4 , Figure 5 As shown, a support 1b is symmetrically arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com